- Gate valve

-

- DIN f4 di flange resilient epdm gate valveDN450-1200 Resilient Seated Gate ValveDIN F5 Non-rising stem Resilient gate valveDIN F5 Socket connection soft seal gate valveUnderground cap soft seal gate valveBS5163 Rising stem Resilient soft seal gate valveBrass Threaded Gate ValveHard seal gate valveAPI Slab Gate ValveStainless Steel Gate ValveStainless Steel Knife Gate ValvePneumatic gate valve Control valveSoft Seal Gate ValveExtension stem gate valveNon rising stem Groove Soft Sealing Gate ValveRising stem Forged steel gate valveAPI carbon steel gate valveThreaded Gate ValveDin rising Stem And Non-Rising Stem Gate ValveUL-FM Rising stem flanged fire fighting system gate valveANSI Cast Iron Gate ValveBritish Standard Soft-Sealing Gate Valve

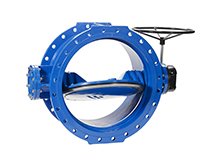

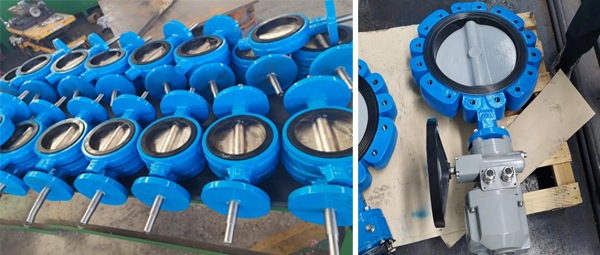

- Butterfly valve

-

- DN2000 Double Eccentric Butterfly ValveFlange butterfly valveLug butterfly valveWafer Butterfly Valve With HandleWorm Gear Operated Wafer Butterfly ValveWafer lined fluorine butterfly valvestainless steel wafer butterfly valveStainless Steel Flanged Butterfly ValveEccentric soft sealing flange butterfly valveElectric three-eccentric metal hard seal butterfly valvePneumatic Flanged Butterfly ValvePneumatic Wafer Butterfly ValveThree eccentric metal seals wafer butterfly valveULC butterfly valve reportInflatable Butterfly ValveHigh Performance Butterfly ValveGrooved butterfly valvesElectric soft sealing wafer butterfly valveDouble flange fluorine lined butterfly valveHandle Aluminum Butterfly ValveWorm Gear Aluminum Butterfly ValveFull PTFE lined wafer butterfly valveOne stem no-pin wafer butterfly valveMulti standard Aluminum handle wafer butterfly valveMulti standard soft seat aluminum lever coated discwafer type butterfly valveResilient Seated Butterfly ValveMulti standard soft seat wafer type butterfly valveWafer PTFE seat butterfly valveWorm Gear Operated Lug Butterfly ValveStainless Steel wafer Butterfly ValvePneumatic Wafer Butterfly ValveWafer Type Metal Seat Butterfly ValveLug type manual wafer butterfly valve without pinAluminium Handle Lug Butterfly ValveWorm Gear Operated Flange Butterfly ValveLever Operated Flange Butterfly ValveButterfly valve stemButterfly valve discButterfly valve seat

- Ball valve

-

- High platform flange ball valveCast Iron Ball ValveSS Thread Ball ValvesThree Piece Type Ball ValveAPI Ball ValveStainless Steel 3PC Ball ValvePTFE Seat Flanged Ball ValveForge Steel Fully Welded Ball ValveMetal Seat Ball Valvesfixed ball valveFlange connection ball valve3PC Type Ball Valve With Internal Thread Q11F/H-1000WOGThree Way Ball ValveANSI API Cast Steel And Stainless Steel Flange Ball valveTwo-PCS Type Thread Ball Valve

- Globe Valve

-

- API Carbon Steel Globe ValveBellows Globe ValveStainless steel flange globe valveStainless steel thread S type globe valveStainless steel thread B type globe valveCast Steel Globe ValvePiston Globe ValveWCB Carbon Steel Globe Check Valveelectric motorized control stainless steel SS316 globe valveBrass Globe ValveCryogenic Globe valveHT200 Globe ValveThreaded Stainless Steel Globe ValveGG25 Globe ValveANSI API Cast Steel And Stainless Steel Globe valve

- Check valve

-

- DN800 Slow Closing Check ValveDN800 Rubber Disc Check ValveButterfly Buffering Check Valvecheck valve with counter weightSilent Check ValveStainless Steel flange Check ValveSwing Check ValveSingle Chip Check Valve H74WStainless Steel Wafer Check ValveSwing Start Check ValveFoot check valveAPI Swing Check ValveWCB Swing Check ValveCheck ValveLifting Check ValveBottom ValveHammer Diminish Noises Check ValveWafer Check ValveDuctile Iron Check Valve

- Water Meter

-

- Vertical Type Water MetersStainless steel threaded water meterPiston water meterPlastic water meterMore flow rotor dry water meterspiral vane flange water meterCI wotlman water meter with pulse outputLXCLG(R) Vertical removable element woltman cold (hot) water meterSingle flow rotor dry water meterPrepaid Token Water MeterElectromagnetic flowmeterRotary Piston Liquid Sealed Water MeterRotary Piston Liquid Sealed Water Meter

- Air valve

-

- Double ball exhaust valveDoubleair Air Valve SaudiDoubleair Air Valve Southeast AsiaDoubleair Air Valve South AmericaDouble Air ValveThreaded Air ValveSingle Air ValveTriple Functions Air ValveAutomatic Air Release ValveAutomatic release valveAutomatic exhaust valveComposite Exhaust Air ValveBrass exhaust valveDouble Ball Air Valve

- Pipe Repair & Coupling

-

- Flexible Multi-Function Pipe Coupling ZFJ-SSS Semi-Circle Pipe Repair Clamp SJW-HDuctile Iron Band Repair ClampStainless Steel Band Repair ClampDouble-Section Pipe Repair CouplingFolding Type Pipe RepairSingle-Section Multi-Function Pipe Coupling MF-SGear-Ring Type Multi-Function Pipe Coupling GR-SZBW Damping Corrugated Hose

- Dismantling Joint

-

- VSSJAFC(CC2F) Detachable Flange Transmission JointVSSJA-2(B2F) Double Flange Limited Expansion JointVSSJA-1(BF) Single Flange Limited Expansion JointVSSJA(AF) Flange Loose Expansion JointJGD-B Threaded Rubber JointZBW Damping Corrugated HoseKXT-S Flexible Dual-Spherical Rubber JointKXT Rubber Soft JointFlange Adaptor

How to choose the valve?

How to choose the valve?

Firstly, we have to master the performance of the medium, flow characteristics, as well as temperature, pressure, flow rate, flow and other performance, and then, combined with the process, operation, safety factors to choose the corresponding type, structure form, model specifications of the valve.

Choose valve according to flow characteristics

The valve opening and closing parts and the shape of the valve flow channel make the valve have certain flow characteristics. This must be taken into account when selecting valves.

(1) cut off or switch on the medium

Usually choose small flow resistance, flow channel for straight - through valve. This kind of valve has gate valve, globe valve, plunger valve. Downward closed valve, because of the tortuous flow channel, flow resistance is higher than other valves, so less selection. However, in situations where high flow resistance is allowed, closed valves can also be used.

(2) control flow valve

Valves that can easily adjust flow are usually selected. Such as regulating valve, throttle valve, plunger valve, because its seat size and the stroke of the firmware is directly proportional. Rotary (such as plug, ball, butterfly) and flexed (clip, diaphragm) valves can also be used for throttling control, but usually only in a limited range of valve sizes. In most cases, the globe valve is usually throttled by changing the disc shape. It should be noted that it is unreasonable to achieve throttling by changing the opening height of gate or globe valves. Because the medium in the pipeline is in the throttling state, the flow rate is very high, the sealing surface is easy to be scoured and worn, and the cutting sealing function is lost. Similarly, it is unreasonable to use the throttle valve as the cutting device.

(3) reversing shunt valve

According to the reversing shunt needs, this valve can have two or more channels, suitable for the selection of plug valves and ball valves. Most of the valves used for reversing shunt use this kind of valve. In some cases, other types of valves, with two or more properly connected to each other, may also be used as reversing shunt for the medium.

(4) Medium valve with suspended particles

If the medium with suspended particles, the most suitable for the use of its opening and closing parts along the sealing surface sliding with wiping valve, such as flat gate valve

Choose valve according to connection mode

There are many types of connection between valve and pipeline, among which the main thread, flange and welding connection.

1. Threaded connection

This connection is usually made by machining the inlet and outlet ends of the valve into a tapered or straight pipe thread to a tapered pipe threaded joint or pipe. Sealant, sealing tape, or packing can be used to block large leak channels because of the potential for such connections. If the body material is weldable, threaded connections can also be sealed. If the material of the connecting parts is allowed to be welded, but the expansion coefficient is very different, or the operating temperature varies greatly, the threaded connection part must be sealed welding only, the threaded connection valve is mainly the nominal diameter of the valve in the following 50mm. If the size is too large, the connection is difficult to install and seal.

To facilitate installation and removal of threaded valves, couplings are available in appropriate locations in the piping system. Valves with nominal sizes up to 50mm May use a sleeve joint as a joint with threads connecting the two connected parts.

2. Flange connection

Flanged valve, its installation and disassembly are more convenient, but more bulky than thread connection, the corresponding price is also high. Therefore, it can be applied to all kinds of diameter and pressure pipe connection. However, when the temperature exceeds 350℃, the load on the bolts will be significantly reduced due to the creep relaxation of bolts, gaskets and flanges, which may cause leakage to flanges with high stress.

3. Weld connection

This connection is suitable for a wide range of pressures and temperatures and is more reliable than flange connections when used in more demanding conditions. However, welded valves are difficult to disassemble and reinstall, so their use is limited to applications where they usually operate reliably for long periods of time, or where conditions are harsh and temperatures are high. Such as thermal power stations, nuclear engineering, ethylene engineering on the pipeline.

Welded valves with nominal sizes up to 50mm usually have a welded socket to accept pipe with flat end. Because the socket welding between the socket and the pipe to form a gap, so it is possible to make the gap by some medium corrosion, at the same time, the vibration of the pipe will make the joint fatigue, so the use of socket welding is limited to a certain extent.

In the nominal condition is larger, the use of harsh conditions, high temperature occasions, the valve body is often used groove butt welding connection, at the same time, there are strict requirements on the weld.

Choose valve according to medium performance

Many media have a certain degree of corrosion, and the same medium, with the change of temperature, pressure and concentration, its corrosion is different. Therefore, the valve suitable for the medium should be selected according to the corrosion resistance of the material.

(1) cast iron valve

①Gray cast iron valve is suitable for water, steam, petroleum products, ammonia, can work in the vast majority of alcohol, aldehyde, ether, ketone, ester and other medium with low corrosion. It is not suitable for hydrochloric acid, nitric acid and other media, but can be used in concentrated sulfuric acid, this is because concentrated sulfuric acid can produce a layer of passivation film on its metal surface, to prevent concentrated sulfuric acid corrosion of cast iron.

② Nodular cast iron valve corrosion resistance is strong, can work in a certain concentration of sulfuric acid, nitric acid, phosphoric acid, acid salt, but not resistant to acid, strong alkali, hydrochloric acid and ferric chloride hot solution corrosion. Use to avoid sudden heat, sudden cold, otherwise it will break.

③ The alkali resistance of austenitized nodular cast iron valve is stronger than that of gray cast iron and nodular cast iron valve. It is used in sparse acid, dilute hydrochloric acid and caustic alkali as well as seawater. The austenitized nodular cast iron valve is an ideal valve material.

(2) carbon steel valve

The corrosion resistance of carbon steel valve is similar to that of gray cast iron, and slightly inferior to that of gray cast iron.

(3) stainless steel valve

Stainless steel valve excellent gas resistance. It can withstand nitric acid and other oxidizing media, but also alkali, water, salt organic acid and other organic compounds corrosion. But it is not resistant to sulfuric acid, hydrochloric acid and other non-fluorinated acid corrosion, also is not resistant to drying hydrogen chloride, oxidizing chloride and oxalic acid, lactic acid and other organic acids.

Stainless steel containing 2% ~ 4% molybdenum, such as Cr18Nil2Mo2Ti, its corrosion resistance is better than chrome-nickel stainless steel, it is better than chrome-nickel stainless steel in non-oxidizing acid and hot organic acid, chloride corrosion resistance than chrome-nickel stainless steel, corrosion resistance is good. Stainless steel containing titanium and yue has a strong resistance to crystal corrosion. Containing high chromium, high nickel stainless steel, its corrosion resistance is higher than ordinary stainless steel, can be used to deal with sulfuric acid, phosphoric acid, mixed acid, sulfuric acid, organic acid, alkali, salt solution, hydrogen sulfide, etc., and even can be used in some concentrations of high temperature occasions. But not resistant to concentrated or hot hydrochloric acid, wet fluorine, chlorine, bromine, iodine, aqua regia corrosion.

(4) copper valve

Copper valve has good corrosion resistance to water, seawater, various salt solutions and organic matter. It has good corrosion resistance to sulfuric acid, phosphoric acid, acetic acid and dilute hydrochloric acid without oxygen or oxidant, and has good resistance to alkali. But it is not resistant to the corrosion of nitric acid, concentrated sulfuric acid and other oxidizing acids, and it is not resistant to the corrosion of molten metal, sulfur and sulfide. Avoid contact with ammonia, which can cause stress corrosion cracking of steel and copper alloys. Attention should be paid to the selection of copper alloy, different grades, its corrosion resistance has a certain difference.

(5) aluminum valve

Strong oxidation of concentrated nitric acid corrosion resistance, resistance to organic acids and solvents. But in reducing medium, strong acid, strong base corrosion resistance. The more pure aluminum is, the better it is against corrosion, but its strength decreases and can only be used for very low pressure valves or valve linings.

(6) titanium valve

Titanium is an active metal and can form an oxide film with good corrosion resistance at room temperature. It can withstand the corrosion of seawater, various chloride and hypochlorite, wet chlorine, oxidizing acid, organic acid, alkali, etc. But it is not resistant to more pure reducing acid, such as sulfuric acid, hydrochloric acid corrosion, but resistance to oxidizing acid corrosion. Titanium valve has good resistance to hole erosion. But in red smoke nitric acid, chloride, methanol and other media will produce stress corrosion.

(7) Zirconium valve

Zirconium also belongs to the active metal, it can generate close oxide film, it has good corrosion resistance to nitric acid, chromic acid, alkali, molten alkali, salt liquid, urea, seawater, but not resistant to oxygen fluoric acid, concentrated sulfuric acid, aqua regia corrosion, also not resistant to wet oxygen and metal oxide chloride corrosion.

(8) Ceramic valve

Valve is given priority to with silicon dioxide fusion sintering, such as zirconia, alumina, silicon nitride, etc., in addition to have extremely high wear resistance, heat resistance, insulation performance, also has the very high corrosion resistant ability, in addition to no oxygen fluorine acid resistance, silicic acid and alkali, hot nitric acid, sulfuric acid, hydrochloric acid, aqua regia, salt solution and organic solvent media. This kind of valve used other materials, when choosing, should consider the corrosion resistance of other materials.

(9) glass valve

Silicon dioxide based valve made of fusion sintering, its corrosion resistance and ceramic valve is the same.

(10) Enamel valve

Silicon dioxide is melted and coated on ferrous metal products with the same corrosion resistance as ceramic valves.

(11) GLASS fiber reinforced plastic valve

The corrosion resistance of FRP, with its adhesive and epoxy resin FRP can be used in hydrochloric acid, phosphoric acid, dilute sulfuric acid and some organic acids phenolic FRP corrosion resistance is better FRP has better alkali resistance, acid resistance and comprehensive corrosion resistance.

(12) Plastic valve

Plastic has a certain corrosion resistance, with different types of plastic, its corrosion resistance varies greatly.

①Nylon, also known as polyamide, is a thermoplastic plastic, has good corrosion resistance. It can resist the corrosion of dilute acid, salt and alkali, and has good corrosion resistance to hydrocarbon, ketone, ether, ester and oil. But not resistant to strong acid, oxidizing acid, phenol and formic acid corrosion.

②Polyvinyl chloride (PVC) is thermoplastic and has excellent corrosion resistance. Resistant to acid, alkali, salt, organic matter, not resistant to concentrated nitric acid, fuming sulfuric acid, acetic anhydride, ketone, halogenated, aromatic and other corrosion.

③Polyethylene has excellent corrosion resistance, it on hydrochloric acid, dilute sulfuric acid. Non-oxidizing acids such as hydrofluoric acid, dilute nitric acid, alkali, salt solution and organic solvent at room temperature all have good corrosion resistance. But not resistant to concentrated nitric acid, sulfuric acid and other strong oxidant corrosion.

④Polypropylene is a thermoplastic material, its corrosion resistance is similar to polyethylene, slightly better than polyethylene. It can withstand most organic acid, inorganic acid, alkali, salt, but to concentrated nitric acid, fuming sulfuric acid and other strong oxidizing acid corrosion resistance.

⑤Phenolic plastics can resist the corrosion of hydrochloric acid, dilute sulfuric acid, phosphoric acid and other non-oxidizing acid and salt solution. But not resistant to nitric acid, chromic acid and other strong oxidizing acid, alkali and two organic solvents corrosion.

⑥ Chlorinated polyether, also known as polychlorine-alkali, is linear, high crystallinity of thermoplastic department, it has excellent corrosion resistance, second only to fluorine plastic. It is capable of concentrated sulfuric acid, concentrated nitric acid outside all kinds of acid, alkali, salt and most organic solvents corrosion, but not resistant to liquid chlorine, fluorine, bromine corrosion.

⑦Polytrifluorovinyl chloride it and other fluorine plastics, has excellent corrosion resistance and other properties, corrosion resistance slightly lower than ptfe. It has good corrosion resistance to organic acid, inorganic acid, alkali, salt and a variety of organic solvents. Certain solvents containing halogens and oxygen that cause them to swell at high temperatures. It is not resistant to high temperature fluorine, chloride, molten alkali, concentrated nitric acid, aromatic, 'fuming nitric acid, molten alkali metal, etc.

⑧Polytetrafluoroethylene has very excellent corrosion resistance, it in addition to molten metal lithium, potassium, sodium, chlorine trifluoride, oxygen trifluoride at high temperature, high flow rate of liquid ammonia, almost all chemical medium corrosion.

⑨Due to the low strength of plastic, many valves are made of metal material and lined with plastic. Plastic lined valves have different corrosion resistance depending on the plastic lining. The corrosion resistance of the plastic lining is the same as that of the corresponding plastic in the plastic valve, but when choosing, the corrosion resistance of other materials used in the plastic lining valve should be considered.

⑩Rubber-lined valves rubber is soft, so many valves are lined with rubber to improve the corrosion resistance and sealing performance of the door. The corrosion resistance of rubber varies greatly with different types of rubber. After vulcanized natural rubber can withstand the corrosion of non-oxidizing acid, alkali, salt, but not resistant to strong oxidants, such as nitric acid, chromic acid, concentrated sulfuric acid corrosion, also not resistant to petroleum products and some organic solvents corrosion. As a result, natural rubber was gradually replaced by synthetic rubber. NBR in synthetic rubber has good mechanical resistance, but it is not resistant to the corrosion of fluorinated acid, aromatic hydrocarbon, ester, ketone, ether and other strong solvents; Fluorine rubber has excellent corrosion resistance, can withstand all kinds of acid, alkali, salt, petroleum products, hydrocarbons, etc., but the solvent resistance is not as good as fluorine plastics; Polyether rubber can be used in water, oil, ammonia, alkali and other media.

Lead is an active metal but is often used as a lining for special valves because it is soft. The corrosion product film of lead is a strong protective layer. It is a famous material resistant to sulfuric acid. It has high corrosion resistance in phosphoric acid, chromic acid, carbonic acid and neutral solution, sea water and other media, but it is not resistant to alkali and hydrochloric acid corrosion, and is not suitable for working in their corrosion products.

To learn more about valve selection expertise, consult our online technical staff.