Cast iron gate valve

Features:

Product model: Z41H-150LBC

Inside Nominal Diameter: DN50-200

Nominal Pressure: PN1.6/2.5mpa

Applicable temperature: ≤425℃

Applicable media: Water .Oil .Gas

Body material : Cast iron

Connecting type : Flange

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is cast iron gate valve?

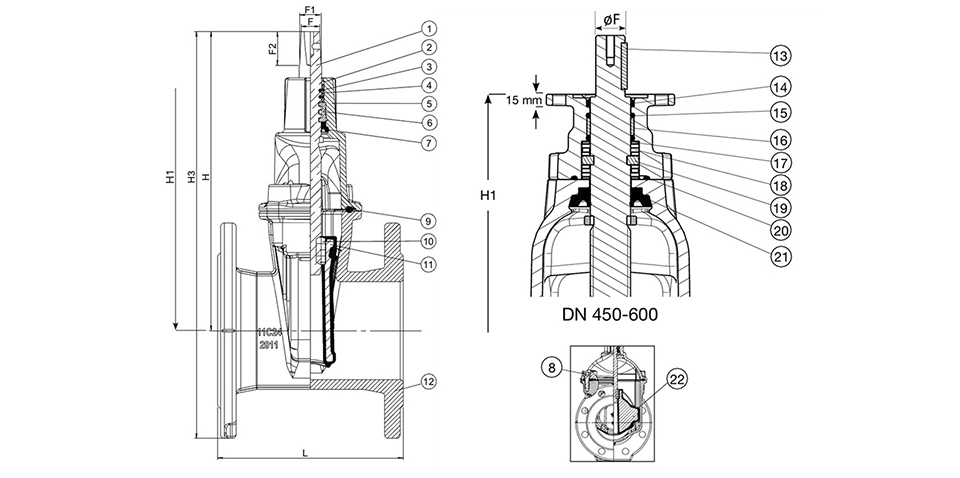

A cast iron gate valve is a type of gate valve made from cast iron material. Cast iron is a strong and durable material commonly used to manufacture valves, pipes, and fittings. The gate valve controls the flow of fluids by using a gate or wedge that moves up and down to open or close the valve.

The cast iron gate valve consists of a valve body, bonnet, gate, stem, and other internal components. The gate is the part that moves up and down to control the flow of fluids. The stem is connected to the gate and is used to move the gate up and down. The valve body is the outer casing that encloses the valve's internal components. The bonnet is the cover that is attached to the valve body and provides access to the internal components for maintenance and repair.

Cast iron gate valves are commonly used in industries such as water supply, wastewater treatment, and irrigation systems. They are preferred over other types of valves due to their durability, strength, and resistance to corrosion. Cast iron gate valves are also used in residential and commercial applications, such as plumbing systems and HVAC systems.

| ANSI GATE VALVE MAIN SPECIFICATONS& CONNECTING SIZE | ||||||||||||||

| DN | DN | SIZE(mm) | ||||||||||||

| OR | d | L | LJ | D | D1 | D2 | b | Z-d | W | H | ||||

| PN | mm | in | ZA40 | ZA540 | ZA940 | |||||||||

| Class150 | 25 | 1 | 25 | 127 | 140 | 108 | 79.5 | 51 | 11.5 | 4--15 | 120 | 200 | - | 330 |

| PN2.0MPa | 32 | 1 ;1/4 | 32 | 140 | 153 | 117 | 89 | 64 | 13 | 4--15 | 140 | 235 | - | 375 |

| 40 | 1 ;1/2 | 38 | 165 | 178 | 127 | 98.5 | 73 | 14.5 | 4--15 | 180 | 285 | - | 435 | |

| 50 | 2 | 51 | 178 | 191 | 152 | 120.5 | 92 | 16 | 4--19 | 180 | 390 | - | 610 | |

| 65 | 2 ;1/2 | 64 | 190 | 203 | 178 | 139.5 | 105 | 17.5 | 4--19 | 200 | 435 | - | 655 | |

| 80 | 3 | 76 | 203 | 216 | 190 | 152.5 | 127 | 19.5 | 4--19 | 200 | 515 | - | 680 | |

| 100 | 4 | 102 | 229 | 242 | 229 | 190.5 | 157 | 24 | 8--19 | 250 | 595 | - | 750 | |

| 125 | 5 | 127 | 254 | 267 | 254 | 216 | 186 | 24 | 8--22 | 250 | 725 | - | 820 | |

| 150 | 6 | 152 | 267 | 280 | 279 | 241.5 | 216 | 25.5 | 8--22 | 300 | 780 | - | 900 | |

| 200 | 8 | 203 | 292 | 305 | 343 | 298.5 | 270 | 29 | 8--22 | 300 | 975 | 1010 | 1060 | |

| 250 | 10 | 254 | 330 | 343 | 406 | 362 | 324 | 30.5 | 12--25 | 350 | 1150 | 1190 | 1250 | |

| 300 | 12 | 305 | 356 | 369 | 483 | 432 | 381 | 32 | 12--25 | 400 | 1380 | 1420 | 1500 | |

| 350 | 14 | 337 | 381 | 394 | 533 | 476 | 413 | 35 | 12--29 | 400 | 1540 | 1580 | 1750 | |

| 400 | 16 | 387 | 406 | 419 | 597 | 540 | 470 | 37 | 16-29 | 500 | 1740 | 1780 | 1950 | |

| 450 | 18 | 438 | 432 | 445 | 635 | 578 | 533 | 40 | 16-32 | 500 | 1950 | 1990 | 2150 | |

| 500 | 20 | 489 | 457 | 470 | 699 | 635 | 584 | 43 | 20-32 | 600 | 2180 | 2220 | 2350 | |

| 600 | 24 | 591 | 508 | 521 | 813 | 749.5 | 692 | 48 | 20-32 | 650 | 2560 | 2600 | 2710 | |

| Class300 | 25 | 1 | 25 | 165 | 178 | 124 | 89 | 51 | 17.5 | 4--19 | 140 | 215 | - | 370 |

| PN5.0MPa | 32 | 1 ;1/4 | 32 | 178 | 191 | 133 | 98.5 | 64 | 19.5 | 4--19 | 180 | 255 | - | 420 |

| 40 | 1 ;1/2 | 38 | 190 | 203 | 156 | 114.5 | 73 | 21 | 4--20 | 200 | 320 | - | 480 | |

| 50 | 2 | 51 | 216 | 232 | 165 | 127 | 92 | 22.5 | 8--19 | 200 | 425 | - | 650 | |

| 65 | 2 ;1/2 | 64 | 241 | 257 | 190 | 149 | 105 | 25.5 | 8--22 | 250 | 460 | - | 700 | |

| 80 | 3 | 76 | 283 | 299 | 210 | 168.5 | 127 | 29 | 8--22 | 300 | 540 | - | 740 | |

| 100 | 4 | 102 | 305 | 321 | 254 | 200 | 157 | 32 | 8--22 | 300 | 630 | - | 795 | |

| 125 | 5 | 127 | 381 | 397 | 279 | 235 | 186 | 35 | 8--22 | 350 | 760 | - | 850 | |

| 150 | 6 | 152 | 403 | 419 | 318 | 270 | 216 | 37 | 12--22 | 350 | 825 | - | 990 | |

| 200 | 8 | 203 | 419 | 435 | 381 | 330 | 270 | 41.5 | 12--25 | 400 | 1020 | 1055 | 1150 | |

| 250 | 10 | 254 | 457 | 473 | 445 | 387.5 | 324 | 48 | 16-29 | 450 | 1200 | 1240 | 1350 | |

| 300 | 12 | 305 | 502 | 518 | 521 | 451 | 381 | 51 | 16-32 | 500 | 1425 | 1465 | 1560 | |

| Class600 | 25 | 1 | 25 | 216 | 216 | 124 | 89 | 51 | 17.5 | 4--19 | 180 | 215 | - | 420 |

| PN10.0MPa | 32 | 1 ;1/4 | 32 | 229 | 229 | 133 | 98.5 | 64 | 21 | 4--19 | 180 | 270 | - | 480 |

| 40 | 1 ;1/2 | 38 | 241 | 241 | 156 | 114.5 | 73 | 22.5 | 4--22 | 200 | 345 | - | 550 | |

| 50 | 2 | 51 | 292 | 295 | 165 | 127 | 92 | 25.5 | 8--19 | 250 | 470 | - | 680 | |

| 65 | 2 ;1/2 | 64 | 330 | 333 | 190 | 149 | 105 | 29 | 8--22 | 250 | 520 | - | 750 | |

| 80 | 3 | 76 | 356 | 359 | 210 | 168.5 | 127 | 32 | 8--22 | 300 | 570 | - | 820 | |

| 100 | 4 | 102 | 432 | 435 | 273 | 216 | 157 | 38.5 | 8--25 | 300 | 700 | - | 870 | |

| 125 | 5 | 127 | 508 | 511 | 330 | 266.5 | 186 | 44.5 | 8--29 | 350 | 780 | - | 950 | |

| 150 | 6 | 152 | 559 | 562 | 356 | 292 | 216 | 48 | 12--29 | 400 | 850 | 890 | 1100 | |

WESDOM Advantages

1.WESDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each wesdom product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All wesdom products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WESDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WESDOM has always been noticed all over the world, and trust comes from quality.

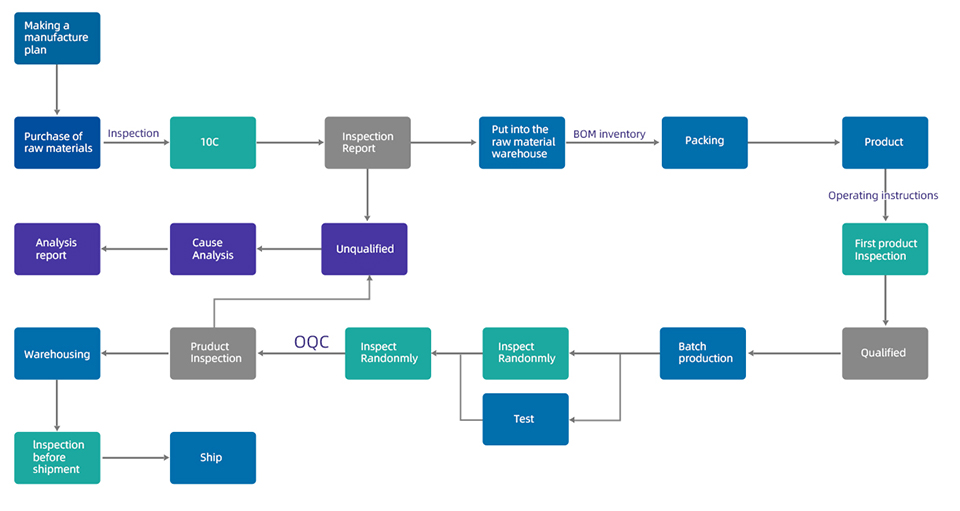

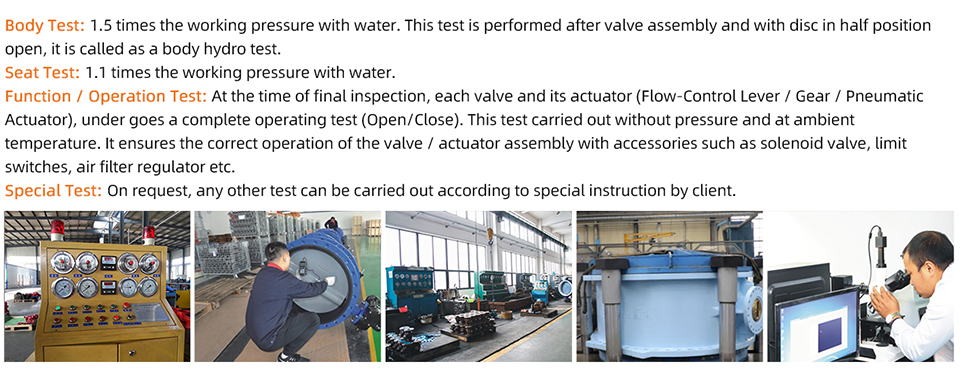

6. WESDOM has a strict quality control system

WESDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Advantages of cast iron gate valve:

Cast iron gate valves offer several advantages over other types of valves. Some of the main advantages of cast iron gate valves include:

1. Durability:

Cast iron is a strong and durable material that can withstand high pressures and temperatures. Cast iron gate valves are designed to last for many years with minimal maintenance, making them a reliable and cost-effective choice for industrial and residential applications.

2. Corrosion Resistance:

Cast iron is naturally resistant to corrosion, making cast iron gate valves ideal for use in environments with high levels of moisture, chemicals, and other corrosive substances. This makes them ideal for use in water supply, wastewater treatment, and irrigation systems.

3. High Flow Capacity:

Cast iron gate valves have a large flow capacity, which means they can handle large volumes of fluids with minimal pressure drop. This makes them ideal for use in applications that require high flow rates, such as water supply systems and HVAC systems.

4. Tight Shut-Off:

Cast iron gate valves are designed to provide a tight shut-off, which means they can effectively control the flow of fluids and prevent leaks. This makes them ideal for use in applications where safety is a top priority, such as in fire protection systems.

5. Easy to Install:

Cast iron gate valves are relatively easy to install, making them a popular choice for residential and commercial plumbing systems. They are also easy to maintain and repair, which helps to extend their lifespan and reduce maintenance costs.

Case:

Tanzania Water Project

Water project of a factory in Tanzania

Main products: Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client feedback:

The customer sent us the installation pictures of the WESDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WESDOM;

Project pictures:

Application:

Application of cast iron gate valve:

Cast iron gate valves are commonly used in a variety of industrial and residential applications due to their durability, strength, and resistance to corrosion. Here are some common applications of cast iron gate valves:

1. Water Supply Systems:

Cast iron gate valves are widely used in water supply systems for controlling the flow of water in pipelines, treatment plants, and distribution systems. They are preferred over other types of valves due to their durability, corrosion resistance, and ability to handle high flow rates.

2. Wastewater Treatment:

Cast iron gate valves are also used in wastewater treatment plants for controlling the flow of sewage and other fluids in pipelines and treatment systems. They are preferred over other types of valves due to their ability to handle corrosive and abrasive fluids.

3. Fire Protection Systems:

Cast iron gate valves are commonly used in fire protection systems for controlling the flow of water and other fire suppression agents. They are preferred over other types of valves due to their ability to provide a tight shut-off, preventing leaks and ensuring reliable operation during emergencies.

4. HVAC Systems:

Cast iron gate valves are used in heating, ventilation, and air conditioning (HVAC) systems for controlling the flow of hot and cold water, steam, and other fluids. They are preferred over other types of valves due to their durability, corrosion resistance, and ability to handle high flow rates.

5. Plumbing Systems:

Cast iron gate valves are commonly used in residential and commercial plumbing systems for controlling the flow of water and other fluids. They are preferred over other types of valves due to their durability, ease of installation, and ability to handle high flow rates.

Please fill in your procurement needs and contact information