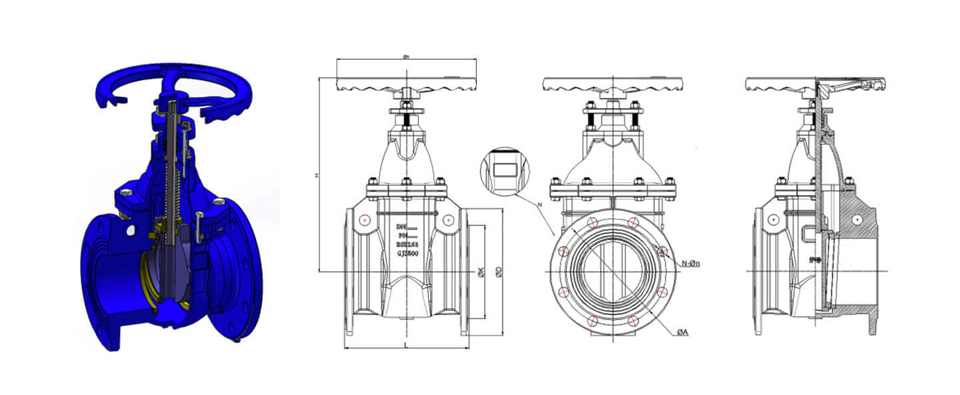

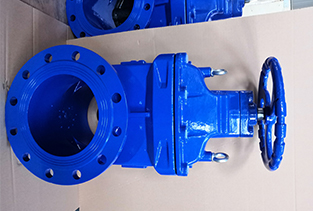

Hard seal gate valve

Features:

Size: 2”~ 12”

Pressure Rating: PN1.0MPa, PN1.6MPa, 150LB

Material: Ductile Iron

Design Standard: DIN3352,MSS SP-70

Inspection Standard: DIN3230,API598

Application medium: water, oil, gas

Application Temperature: 0-120℃

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is a hard seal gate valve?

|

DN |

L |

d |

C |

x-n |

T |

f |

g |

|||

|

50 |

178 |

165 |

125 |

4-18 |

19 |

2 |

99 |

|||

|

65 |

190 |

185 |

145 |

4-18 |

19 |

2 |

118 |

|||

|

80 |

203 |

200 |

160 |

4-18 |

8-18 |

19 |

3 |

132 |

||

|

100 |

229 |

220 |

180 |

8-18 |

19 |

3 |

156 |

|||

|

125 |

254 |

250 |

210 |

8-18 |

19 |

3 |

184 |

|||

|

150 |

267 |

285 |

240 |

8-23 |

19 |

3 |

211 |

|||

|

200 |

292 |

340 |

295 |

8-23 |

12-23 |

21 |

3 |

266 |

||

|

250 |

330 |

395 |

350 |

355 |

12-23 |

12-25 |

22 |

3 |

319 |

|

|

300 |

355 |

445 |

400 |

410 |

12-23 |

12-25 |

25 |

4 |

370 |

|

|

350 |

381 |

515 |

460 |

470 |

16-23 |

16-25 |

25 |

4 |

430 |

|

|

400 |

405 |

580 |

515 |

525 |

16-26 |

16-31 |

28 |

4 |

475 |

|

|

450 |

432 |

650 |

565 |

585 |

20-26 |

20-31 |

29 |

5 |

530 |

|

|

500 |

457 |

670 |

715 |

620 |

650 |

20-26 |

20-34 |

29 |

5 |

580 |

|

600 |

508 |

780 |

810 |

725 |

770 |

20-30 |

20-36 |

38 |

5 |

680 |

WESDOM Advantages

1.WESDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each wesdom product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All wesdom products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WESDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WESDOM has always been noticed all over the world, and trust comes from quality.

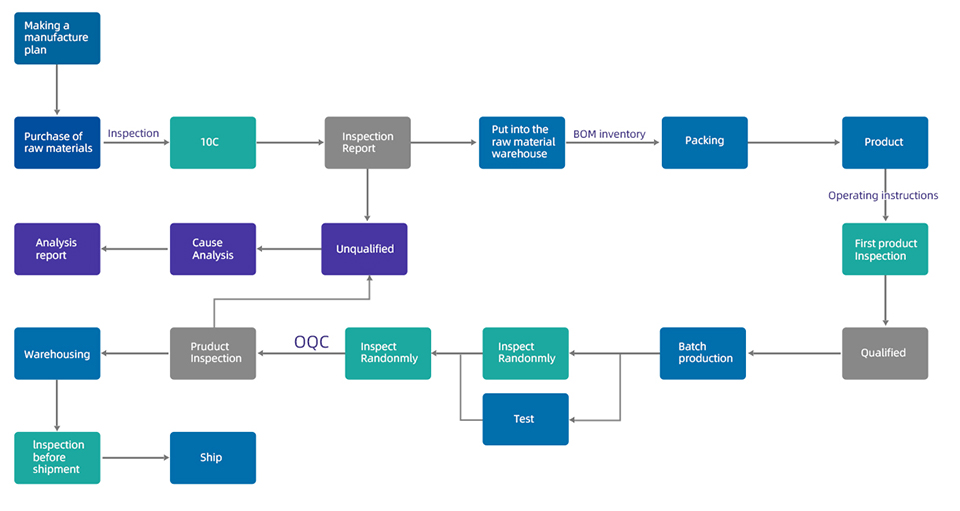

6. WESDOM has a strict quality control system

WESDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

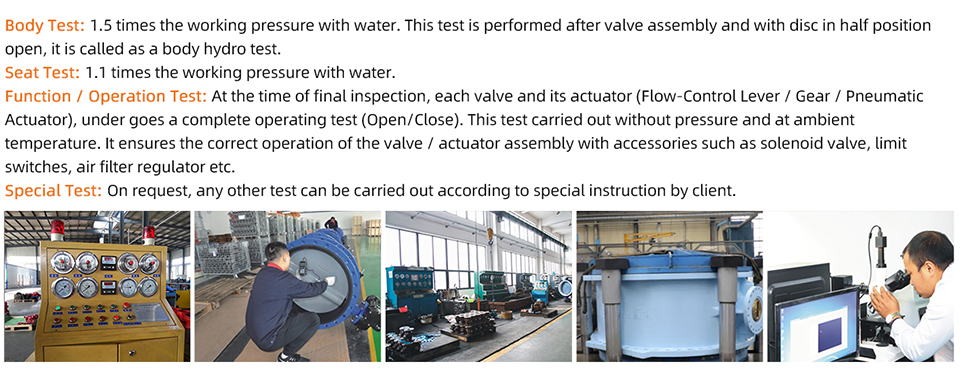

Standards&Features:

Advantages of hard seal gate valve:

1.High durability:

The metal-to-metal seal in hard seal gate valves makes them highly resistant to wear, erosion, and corrosion, providing a longer service life.

2.High temperature resistance:

Hard seal gate valves can withstand high temperatures and are therefore ideal for applications where high-temperature fluids are present.

3.Tight shut-off:

The metal-to-metal seal provides a tight shut-off, preventing any fluid from passing through the valve.

4.Low leakage:

The tight shut-off provided by hard seal gate valves results in low leakage rates, which is important for applications where leakage can be hazardous or costly.

5.Low maintenance:

Hard seal gate valves require minimal maintenance due to their durable construction and metal-to-metal seal, resulting in lower maintenance costs and reduced downtime.

6.Better performance:

Hard seal gate valves provide superior performance compared to soft-seated gate valves in high-pressure and high-temperature applications, making them suitable for a wide range of industrial applications.

The main differences between hard seal gate valves and soft seal gate valves are as follows:

1. Sealing mechanism:

Hard seal gate valves use a metal-to-metal seal between the gate and the valve seat, while soft seal gate valves use a soft material such as rubber or elastomer to create a seal between the gate and the valve seat.

2. Operating torque:

Hard seal gate valves require more operating torque compared to soft seal gate valves due to the metal-to-metal seal, which can result in longer closing times and increased wear on the valve components.

3. Leakage rate:

Hard seal gate valves provide a tighter shut-off compared to soft seal gate valves, resulting in lower leakage rates.

4. Temperature and pressure resistance:

Hard seal gate valves are better suited for high-temperature and high-pressure applications compared to soft seal gate valves, which may deform or fail under extreme conditions.

5. Maintenance requirements:

Hard seal gate valves require more maintenance compared to soft seal gate valves due to the metal-to-metal seal, which can wear over time and require replacement.

Overall, hard seal gate valves offer better durability, temperature, pressure resistance, and tighter shut-off than soft seal gate valves but require more maintenance and operating torque. Soft seal gate valves are generally less expensive and require less maintenance but may not be suitable for high-temperature or high-pressure applications. The choice between hard and soft seal gate valves depends on the application requirements and operating conditions.

Case:

A customer in Pakistan purchases check valves, gate valves, pipe fittings, etc.

Main products: check valve, gate valve, pipe fittings, etc.

client feedback:

We have worked with WESDOM many times and have been very satisfied each time. We are very willing to maintain a long-term cooperative relationship with WESDOM.

Project pictures:

Application:

Application of hard seal gate valve:

Hard seal gate valves are used in a wide range of industrial applications where high-pressure and high-temperature fluids need to be controlled and shut off. Some common applications of hard seal gate valves include:

1. Oil and gas industry:

Hard seal gate valves are commonly used in the oil and gas industry for controlling the flow of crude oil, natural gas, and other fluids in pipelines, refineries, and offshore drilling platforms.

2. Power generation:

Hard seal gate valves are used in power plants to control the flow of steam, gas, and other fluids in boilers, turbines, and other equipment.

3. Chemical processing:

Hard seal gate valves are used in chemical processing plants to control the flow of corrosive and abrasive fluids in pipelines, reactors, and other equipment.

4. Water treatment:

Hard seal gate valves are used in water treatment plants for controlling the flow of water, wastewater, and chemicals in pipelines, pumps, and other equipment.

5. Mining:

Hard seal gate valves are used in mining operations for controlling the flow of water, slurries, and other fluids in pipelines, pumps, and other equipment.

Overall, hard seal gate valves are well-suited for applications with high pressures, high temperatures, and corrosive or abrasive fluids, making them an essential component in many industrial processes.

Please fill in your procurement needs and contact information