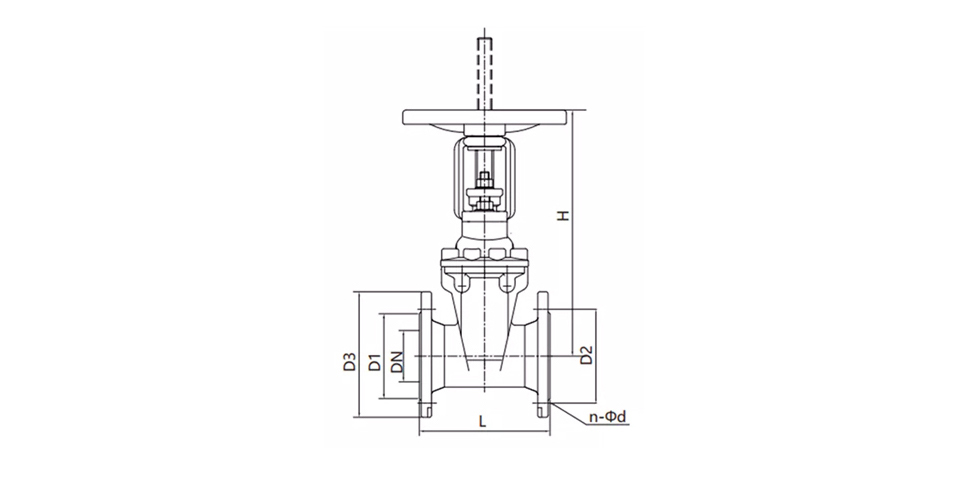

BS5163 rising stem soft seal gate valve

Features:

Size: DN50-DN300

Pressure Rating: PN16/PN25

Material: Ductile Iron/Cast Iron

Design Standard: BS 5163

Inspection Standard: EN558

Application medium: Drinking water or other neutral liquid

Application Temperature: -10C°-80C°

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is a rising stem gate valve?

A rising stem gate valve is a fluid control valve that effectively controls the flow of fluid in a pipeline. Gate valves have the advantages of fast fluid shut-off, simplicity, reliability, and ease of maintenance. The gate valve has a flat, rectangular, or trapezoidal-shaped valve plate and is free to move within the grooves of the gate body to control the fluid in the pipeline by raising and lowering the valve plate. The rising stem gate valve is a fluid control valve that has a distinct trajectory of action, so called because the actuator such as a lever or handwheel rises and falls distinctly when opening and closing the valve.

|

DN |

L(F4) |

L(BS) |

D1 |

D2 |

D3 |

H |

N-øD |

|

|

|

|

|

|

|

|

|

PN10 |

PN16 |

|

50 |

150 |

178 |

99 |

125 |

165 |

220 |

4-ø19 |

4-ø19 |

|

65 |

170 |

190 |

118 |

145 |

185 |

240 |

4-ø19 |

4-ø19 |

|

80 |

180 |

203 |

132 |

160 |

200 |

290 |

8-ø19 |

8-ø19 |

|

100 |

190 |

229 |

156 |

180 |

220 |

330 |

8-ø19 |

8-ø19 |

|

125 |

200 |

254 |

184 |

210 |

250 |

375 |

8-ø19 |

8-ø19 |

|

150 |

210 |

267 |

211 |

240 |

285 |

420 |

8-ø23 |

8-ø23 |

|

200 |

230 |

292 |

266 |

295 |

340 |

500 |

8-ø23 |

12-ø23 |

|

250 |

250 |

330 |

319 |

355 |

405 |

610 |

12-ø23 |

12-ø28 |

|

300 |

270 |

356 |

370 |

410 |

460 |

720 |

12-ø23 |

12-ø28 |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

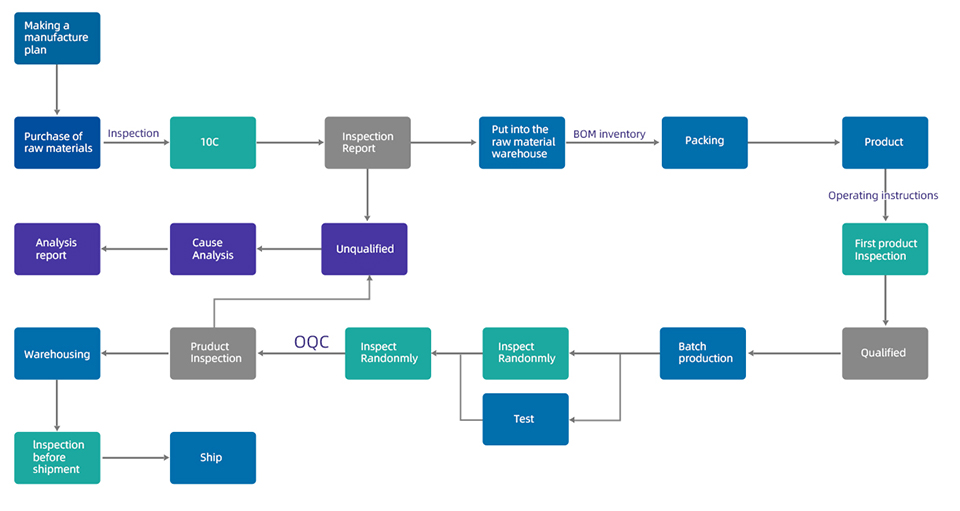

6. WEIZIDOM has a strict quality control system

Quality Control Process

Standards&Features:

Rising stem gate valves have the following advantages:

Easy to install and maintain:

The relatively simple structure of the rising stem gate valve makes it easier to install and maintain.

Low flow resistance:

The valve does not have any internal protrusions, and the resistance of the flow pipe is relatively small.

Good sealing:

The sealing surface is flat and the sealing performance is good, there will be no air leakage, liquid leakage, and so on.

Wide range of applications:

The rising stem gate valve is suitable for a variety of media, temperatures, pressure, pipe diameter, and other occasions.

High reliability:

As it is the gate plate lifting to control the fluid flow, it will not be eroded or polluted by the medium and has a long service life.

Difference of non-rising stem gate valve and rising stem gate valve:

1. The stem of the rising stem gate valve is exposed and can be seen, while the stem of the non-rising stem gate valve is in the valve body and cannot be seen.

2. The rising stem gate valve is driven by the threaded drive of the stem and the steering wheel, thus driving the gate up and down; the non-rising stem gate valve is driven by the rotation of the stem at a fixed point to drive the gate up and down, and the steering wheel and the stem are connected together in a relatively immobile manner when switching.

3. The transmission thread of the non-rising stem gate valve is located inside the valve body, in the process of opening and closing the valve, the stem only does rotational movement in situ, and the naked eye cannot judge the opening and closing state of the valve; while the transmission thread on the stem of the rising stem gate valve is exposed on the outside of the valve body, which can intuitively judge the opening and closing of the gate and its position.

4. The height of the non-rising stem gate valve is small and the installation space is relatively small; the height of the rising stem gate valve is larger when it is fully open and requires a larger installation space.

5. The stem of the rising stem gate valve is outside the valve body, which is conducive to maintenance and lubrication; the stem of the non-rising stem gate valve is threaded inside the valve body, which makes maintenance and lubrication difficult, and the stem is susceptible to direct erosion by the medium, and the valve is easily damaged. In the scope of use, the rising stem gate valve is more extensive.

Case:

Tanzania Water Project

Main products: Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client feedback:

The customer sent us the installation pictures of the WEIZIDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WEIZIDOM;

Project pictures:

Application:

With the advantages of simple structure, good sealing performance, low flow resistance, and easy operation, rising stem gate valves are widely used in various industrial fields, such as chemical, petroleum, natural gas, water treatment, and power industries.

Common applications include:

1. Drainage pipes in sewage treatment systems.

2. Water supply pipes in fire hydrant systems.

3. Pipeline control in industrial production processes.

4. Fluid control in the automotive industry.

5. Gas piping control in the metallurgical industry.

6. Pipeline control in the oil and gas industry.

Please fill in your procurement needs and contact information