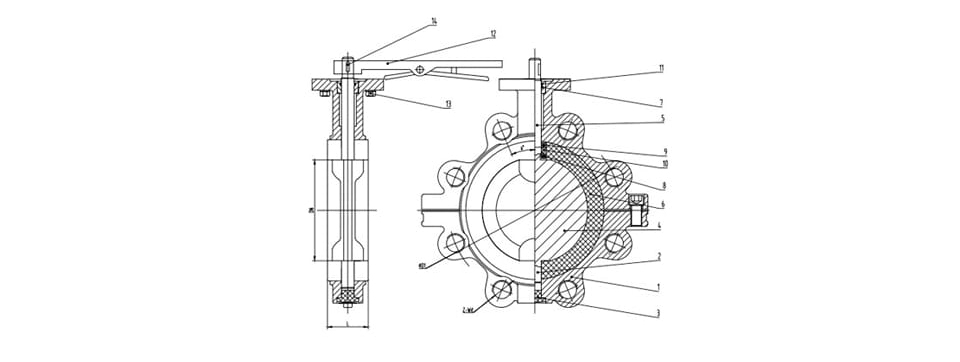

Aluminium handle operated lug butterfly valve

Features:

DN: DN40~DN500

Nominal pressure: PN10, PN16, Class125

Body Materials: Cast Iron, Ductile Iron, WCB , Stainless Steel, Bronze

Seat Materials: NBR, EPDM, VITON, PTFE

Disc Materials: Ductile Iron, WCB, CF8,CF8M, Al-bronze C958

Stem Materials: SS416, SS304, SS316

End Connection: Lug

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is an aluminium handle operated lug butterfly valve?

An aluminum handle operated lug butterfly valve is a type of butterfly valve that features a handle made of aluminum for manual operation. The valve is designed with lugs (protrusions on the valve body) that allow it to be mounted directly onto a pipeline using bolts. The valve is used to regulate the flow of fluid or gas in a pipeline. The valve features a disc that rotates around a central axis to regulate the flow of fluid or gas through the valve.

The aluminum handle is lightweight, durable, and corrosion-resistant, making it an ideal choice for use in a variety of applications. The valve is commonly used in the water treatment, HVAC, and agriculture industries, among others. The lug design of the valve allows for easy installation and removal, making it a popular choice for applications where frequent maintenance is required.

| DN | øD1 | øD2 | øD3 | øD4 | øD5 | øD6 | □T | ød | N-M | A | B | C | D | 4- ød1 |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm | mm |

| 40 | 42.3 | 110 | 86 | 50 | 65 | 12.6 | 9 | 18 | 4-M16 | 212 | 110 | 32 | 32 | 7 |

| 50 | 52.6 | 125 | 100 | 50 | 65 | 12.6 | 9 | 18 | 4-M16 | 273 | 161 | 32 | 43 | 7 |

| 65 | 64.3 | 145 | 120 | 50 | 65 | 12.6 | 9 | 18 | 4-M16 | 296 | 175 | 32 | 46 | 7 |

| 80 | 78.8 | 160 | 127 | 50 | 65 | 12.6 | 9 | 18 | 8-M16 | 308 | 181 | 32 | 46 | 7 |

| 100 | 104 | 180 | 156 | 70 | 90 | 15.77 | 11 | 18 | 8-M16 | 346 | 200 | 32 | 52 | 10 |

| 125 | 123.3 | 210 | 190 | 70 | 90 | 18.92 | 14 | 18 | 8-M16 | 372 | 213 | 32 | 56 | 10 |

| 150 | 155.7 | 240 | 212 | 70 | 90 | 18.92 | 14 | 22 | 8-M20 | 397 | 226 | 32 | 56 | 10 |

| 200 | 202.4 | 295 | 268 | 102 | 125 | 22.1 | 17 | 22 | 8-M20 | 480 | 260 | 45 | 60 | 12 |

| 250 | 250.4 | 350 | 325 | 102 | 125 | 28.45 | 19 | 22 | 12-M20 | 540 | 292 | 45 | 68 | 12 |

| 300 | 301.5 | 400 | 376 | 102 | 125 | 31.6 | 22 | 22 | 12-M20 | 624 | 337 | 45 | 78 | 12 |

| 350 | 333.3 | 460 | 436 | 102 | 125 | 31.6 | 22 | 22 | 16-M20 | 680 | 368 | 45 | 78 | 12 |

| 400 | 389.6 | 515 | 488 | 140 | 175 | 33.15 | 24 | 26 | 16-M24 | 763 | 400 | 51 | 102 | 18 |

| 450 | 440.5 | 565 | 539 | 140 | 175 | 37.95 | 27 | 26 | 20-M24 | 800 | 422 | 51 | 114 | 18 |

| 500 | 491.6 | 620 | 593 | 140 | 175 | 41.12 | 36 | 26 | 20-M24 | 897 | 480 | 57 | 127 | 18 |

WESDOM Advantages

1.WESDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each wesdom product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All wesdom products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

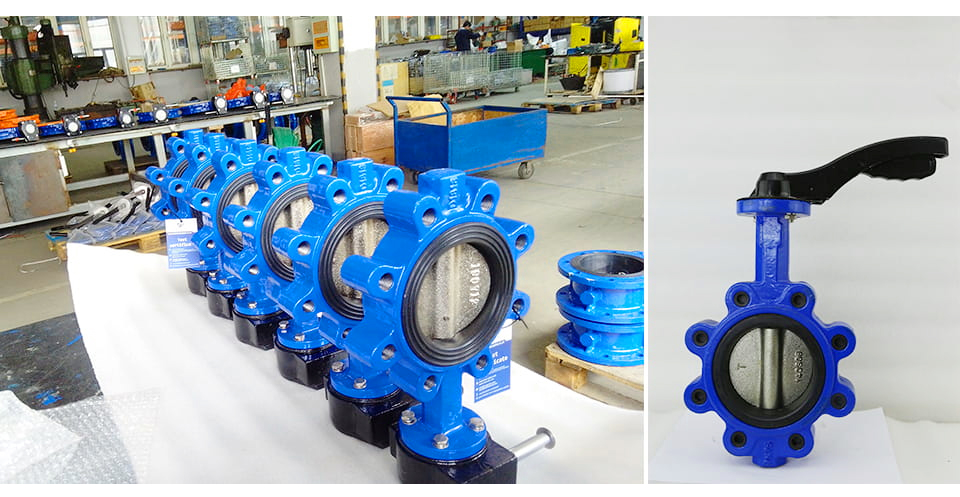

5.WESDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WESDOM has always been noticed all over the world, and trust comes from quality.

6. WESDOM has a strict quality control system

WESDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Body Test:

1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test:

1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test:

On request, any other test can be carried out according to special instruction by client.

Advantages of aluminium handle operated lug butterfly valve:

1. Saves raw materials and installation space

The length of the short structure can save raw materials and installation space and also effectively support the strength of the pipeline.

2. Good sealing performance

The valve block is the correct movement of the gate, extrusion fast, to ensure an effective sealing valve.

3. Good mechanical performance

Triangle support material guarantees the required mechanical properties.

4. Suitable for all working conditions

According to different working conditions, demand design V, triangle, or five corners and other ports in order to meet the needs of various flow regulations.

5. Good flow performance

No groove at the bottom to make sure no slag and full bore flow.

6. Strict implementation of the standard specifications

Wesdom valve strict implementation of the API598 experimental standard, for each product to implement 100% positive and negative double pressure test, guarantee delivery to customers is 100% qualified products.

Case:

WESDOM Group specializes in pipeline fluid systems:

R&D, production and sales of valves, pipe fittings, water meters, flow meters, etc. The products cover cast iron, cast steel, stainless steel, copper, plastics and other materials, which are widely used in hydropower stations, heat, buildings, Water supply and drainage, petroleum, chemical industry, electric power, medical and other fields.

1. There is a professional technical team, and quality is guaranteed

2. Independent factory, more favorable price

3. Extensively trained employees are well-versed in all aspects of flow control technology

Application:

Application of aluminium handle operated lug butterfly valve:

1. Water treatment:

These valves are commonly used in water treatment plants to control the flow of water and other fluids.

2. HVAC systems:

Butterfly valves are used in heating, ventilation, and air conditioning (HVAC) systems to regulate the flow of air and other gases.

3. Agriculture:

These valves are used in agricultural irrigation systems to control the flow of water and other fluids.

4. Chemical processing:

Aluminum handle operated lug butterfly valves are used in the chemical industry to regulate the flow of corrosive liquids and gases.

5. Industrial applications:

These valves are used in various industrial applications to control the flow of fluids and gases.

6. Power generation:

Butterfly valves are used in power plants to regulate the flow of steam and other fluids.

Please fill in your procurement needs and contact information