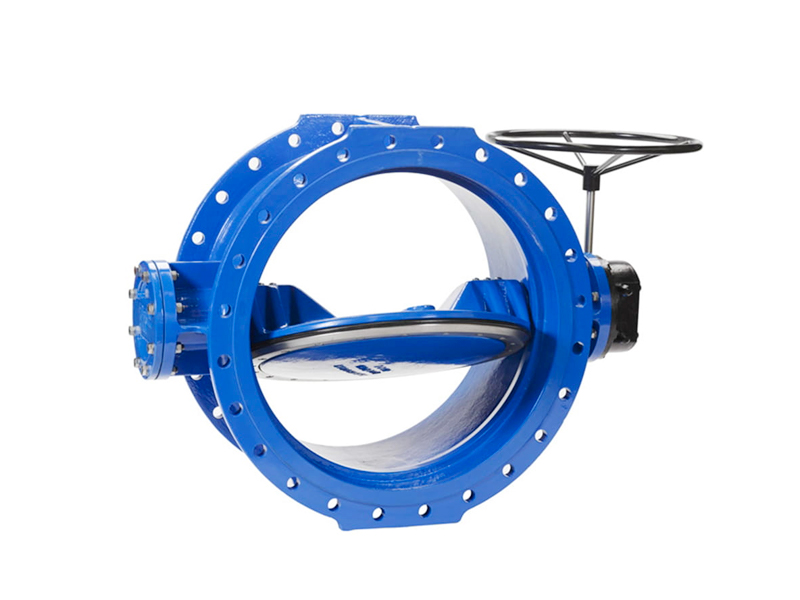

Three eccentric flange butterfly valve

Features:

Size Range: 2"-48"

Deaign standard: API 609

Test inspection: API598

Working temperature: 304/316 seat: -73-+450℃

Pressure: CLASS 150-CLASS 900

Suitable medium: Water, Oil and gasFresh water / Sea water / Salts water / Steam / Gas / Air etc

We're here to help:

Easy ways to get the answers you need.

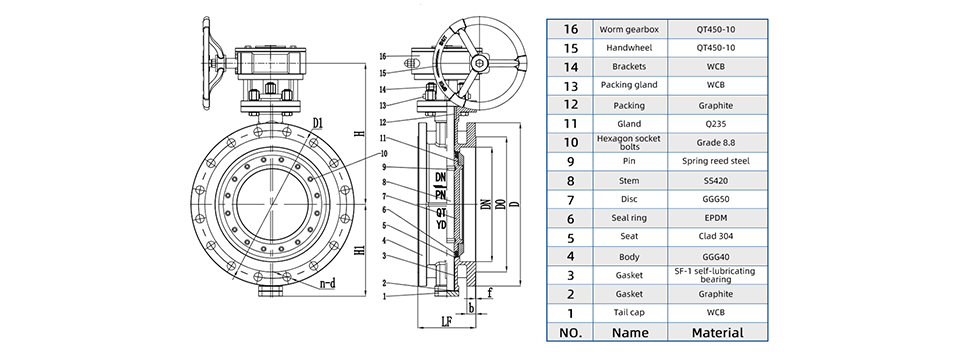

Parameter:

Brief introduction of three eccentric butterfly valve:

This series of butterfly valves is a new generation of patented products which is independently researched and developed by our company, no pin connection is through a valve rod milling flat straight connected with the butterfly plate matched, with countersunk head bolt is fixed, is more convenient in assembly, firmer connection security. Use triple eccentric sealing structure, no mechanical wear, can achieve zero leakage, with bidirectional sealing function superior, is used as the best device in oil, chemical industry, metallurgy, electric power, building materials, food, medicine, water supply, and drainage, gas delivery of different media, such as adjust, cut off or connected to the fluid flow.

WEIZIDOM valves are installed all over Asia, Africa continent, the Middle East, and throughout Europe. They have justifiably acquired a faultless reputation for their durability, reliability, and quality worldwide.

| DN | Main ouler size | Main connection size | |||||||||||||||

| 0.6Mpa | 1.0Mpa | 1.6Mpa | |||||||||||||||

| L | H | H1 | A | B | D | D1 | D2 | n-d | D | D1 | D2 | n-d | D | D1 | D2 | n-d | |

| 50 | 108 | 825 | 306 | 80 | 80 | 140 | 110 | 88 | 4-14 | 165 | 125 | 99 | 4-18 | 165 | 125 | 99 | 4-18 |

| 65 | 112 | 925 | 321 | 80 | 80 | 160 | 130 | 108 | 4-14 | 195 | 145 | 118 | 4-18 | 185 | 145 | 118 | 4-18 |

| 80 | 114 | 100 | 346 | 80 | 80 | 190 | 150 | 124 | 4-18 | 200 | 160 | 132 | 8-18 | 200 | 160 | 132 | 8-18 |

| 100 | 127 | 110 | 37 | 95 | 95 | 210 | 170 | 144 | 4-18 | 220 | 180 | 156 | 8-18 | 220 | 180 | 156 | 8-18 |

| 125 | 140 | 125 | 411 | 95 | 95 | 240 | 200 | 174 | 8-18 | 250 | 210 | 184 | 8-18 | 250 | 210 | 184 | 8-18 |

| 150 | 140 | 1425 | 447 | 95 | 95 | 265 | 225 | 199 | 8-18 | 285 | 240 | 211 | 8-22 | 2B5 | 240 | 211 | 8-2 |

| 200 | 152 | 170 | 607 | 190 | 300 | 320 | 280 | 254 | 8-18 | 340 | 295 | 266 | 8-22 | 340 | 296 | 266 | 12-22 |

| 260 | 165 | 1925 | 688 | 190 | 308 | 376 | 335 | 309 | 12-18 | 396 | 350 | 319 | 12-22 | 405 | 355 | 319 | 12-26 |

| 300 | 178 | 2225 | 742 | 190 | 308 | 440 | 395 | 363 | 12-22 | 445 | 400 | 370 | 12-22 | 480 | 410 | 370 | 12-26 |

| 350 | 190 | 2525 | 797 | 190 | 30B | 490 | 445 | 413 | 12-22 | 505 | 460 | 429 | 16-22 | 520 | 470 | 429 | 16-26 |

| 400 | 216 | 2825 | 930 | 270 | 486 | 540 | 495 | 463 | 16-22 | 565 | 515 | 480 | 16-26 | 580 | 525 | 480 | 16-30 |

| 450 | 222 | 3075 | 975 | 270 | 486 | 566 | 550 | 518 | 16-22 | 615 | 565 | 530 | 20-26 | 640 | 585 | 548 | 20-30 |

| 500 | 229 | 335 | 1065 | 270 | 486 | 645 | 600 | 568 | 20-22 | 670 | 620 | 6R2 | 20-26 | 715 | 650 | 609 | 20-33 |

| 600 | 267 | 390 | 1225 | 457 | 625 | 755 | 705 | 667 | 20-26 | 780 | 725 | 682 | 20-30 | 840 | 770 | 720 | 20-36 |

| 700 | 292 | 4475 | 1343 | 457 | 625 | 860 | 810 | 772 | 24-26 | 895 | 840 | 794 | 24-30 | 910 | 840 | 794 | 24-36 |

| 800 | 318 | 5075 | 1436 | 457 | 625 | 975 | 920 | 878 | 24-30 | 1015 | 950 | 901 | 24-33 | 1025 | 950 | 901 | 24-39 |

| 900 | 330 | 5575 | 1616 | 598 | 853 | 1075 | 1020 | 978 | 24-30 | 115 | 1050 | 1001 | 28-33 | 1125 | 1050 | 1001 | 28-39 |

| 1000 | 410 | 615 | 1711 | 598 | 853 | 1175 | 1120 | 1078 | 28-30 | 1230 | 1160 | 1112 | 28-36 | 1255 | 1170 | 112 | 28-42 |

| 1200 | 470 | 7275 | 1971 | 598 | 853 | 1405 | 1340 | 1295 | 32-33 | 1455 | 1380 | 1328 | 32-39 | 1485 | 1380 | 1328 | 32-48 |

| 1400 | 530 | 8375 | 2218 | 860 | 1345 | 1630 | 1560 | 1510 | 36-36 | 1675 | 1590 | 1530 | 36 -42 | 16865 | 1590 | 1530 | 36-48 |

| 1600 | 600 | 957.5 | 2578 | 880 | 1345 | 1800 | 1760 | 1710 | 40-36 | 1915 | 1820 | 1750 | 40-48 | 1990 | 1820 | 1760 | 40-56 |

| 1800 | 670 | 1067.5 | 2689 | 880 | 1345 | 2045 | 1970 | 1918 | 44-39 | 2115 | 2020 | 1950 | 4448 | 2130 | 2020 | 1960 | 44-56 |

| 2000 | 760 | 1162.5 | 3022 | 952 | 1592 | 2265 | 2180 | 2125 | 48-42 | 2325 | 2230 | 2150 | 48-48 | 2345 | 2230 | 2150 | 48-82 |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

The difference between a three-eccentric metal hard seal butterfly valve and a double eccentric butterfly valve:

The main difference between a three-eccentric metal hard seal butterfly valve and a double eccentric butterfly valve is in their design and functionality.

1. Reduced friction and increased valve life:

A double eccentric butterfly valve has two points of contact between the disc and the valve seat, creating a seal when the valve is closed. This design reduces the amount of torque required to operate the valve and increases the valve's service life. However, the double eccentric design is prone to wear and tear over time, which can cause leaks and reduce the efficiency of the valve.

2. Less prone to leakage:

On the other hand, a three-eccentric metal hard seal butterfly valve has three points of contact between the disc and the valve seat, which creates a seal that is not subject to wear and tear. This design allows the valve to maintain a tight seal even after prolonged use, which reduces the risk of leaks and enhances the efficiency of the valve.

3. Better suited to high flow, high pressure, and corrosive service conditions:

Another difference between the two types of valves is in their applications. Double eccentric butterfly valves are typically used in applications where moderate to high flow rates are required, while three-eccentric metal hard seal butterfly valves are used in applications where high flow rates, high pressure, and/or abrasive or corrosive fluids are present.

The advantages of a three-eccentric metal hard seal butterfly valve include:

1. Tight seal:

The three-eccentric design of the valve creates a seal that is not subject to wear and tear, providing a tight seal that minimizes the risk of leaks and contamination.

2. High flow capacity:

The valve's disc is designed to rotate around the shaft, allowing for high flow rates and low-pressure drops, making it ideal for applications requiring high flow capacity.

3. Low torque:

The three-eccentric design of the valve reduces the amount of torque required to operate the valve, making it easier to use and more efficient than other types of valves.

4. Long service life:

The metal hard seal and three-eccentric design of the valve make it highly durable, with a long service life that reduces the need for frequent replacements.

5. Corrosion-resistant:

The valve is made of high-quality materials such as stainless steel or titanium, making it highly resistant to corrosion and suitable for use with corrosive fluids.

6. Remote operation:

The electric actuator on the valve allows for remote operation of the valve, making it ideal for applications where manual operation of the valve is not practical or safe.

Case:

Tanzania Water Project

Main products: Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client feedback:

The customer sent us the installation pictures of the WEIZIDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WEIZIDOM;

Project pictures:

Application:

Three eccentric flange butterfly valves are widely used in various industries for regulating the flow of fluids and gases in high-temperature and high-pressure applications. Some common applications of three eccentric flange butterfly valves include:

1. Oil and gas industry:

Three eccentric flange butterfly valves are commonly used in the oil and gas industry for regulating the flow of various fluids and gases, controlling pressure, and isolating different parts of the system.

2. Chemical processing:

Three eccentric flange butterfly valves are widely used in chemical processing industries for regulating the flow of various chemicals and fluids, controlling pressure, and isolating different parts of the system.

3. Power generation:

Three eccentric flange butterfly valves are used in power generation plants for regulating the flow of steam and gas, controlling pressure, and isolating different parts of the system.

4. Water treatment:

Three eccentric flange butterfly valves are used in water treatment plants for regulating the flow of water, controlling pressure, and isolating different parts of the system.

5. HVAC systems:

Three eccentric flange butterfly valves are also used in heating, ventilation, and air conditioning (HVAC) systems for regulating the flow of air and controlling temperature and humidity.

Please fill in your procurement needs and contact information