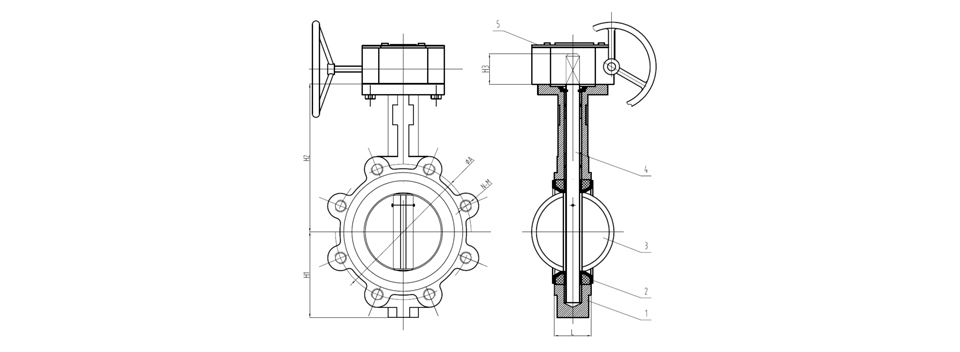

Lug butterfly valve

Features:

Size: 2”~24”

Pressure Rating: PN10/PN16, 150LB

Material: Ductile Iron, WCB, Stainless Steel

Design Standard: BS 5155,EN593, API 609

Inspection Standard: EN12266, API 598,GB/T 13927-92

Application medium: Water, Sewage, Gas

Application Temperature: -10℃~120'℃

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is a lug butterfly valve?

The driving method of the lug butterfly valve can be used by manual, worm-gear, pneumatic, and electric. The connection method can be used for flanges and clamps. Structural forms can be used for single eccentric, middle line, double eccentric, triple eccentric. Seal structure can choose soft seal, hard seal, and the pressure range PN0.1-10Mpa. The nominal diameter is DN40 ~ 2000mm. The material can choose cast steel and stainless steel. Due to the extensive range of valves, the same valve has different combinations in different occasions and working conditions .

The disc of the wafer lug butterfly valve is installed in the diameter direction of the pipe. In the cylindrical channel of the butterfly valve body, the disc rotate around the axis, and the rotation angle is between 0°and 90°. When rotating to 90°, the valve is fully open.

| DN | A | B | C | D | ISO5211 | n-ød | K | E | D1 | N-M | ||

| PN10 | PN16 | PN10 | PN16 | |||||||||

| 50 | 161 | 80 | 42 | 52.9 | F07 | 4-09 | 90 | 70 | 125 | 125 | 4-M16 | 4-M16 |

| 65 | 175 | 89 | 44.7 | 64.5 | F07 | 4-ø9 | 90 | 70 | 145 | 145 | 4-M16 | 4-M16 |

| 80 | 181 | 95 | 45.2 | 78.8 | F07 | 4-ø9 | 90 | 70 | 160 | 160 | 8-M16 | 8-M16 |

| 100 | 200 | 114 | 52 | 104 | F07 | 4-ø9 | 90 | 70 | 180 | 180 | 8-M16 | 8-M16 |

| 125 | 213 | 127 | 55.4 | 123.3 | F07 | 4-ø9 | 90 | 70 | 210 | 210 | 8-M16 | 8-M16 |

| 150 | 226 | 139 | 55.8 | 155.1 | F07 | 4-ø9 | 90 | 70 | 240 | 240 | 8-M20 | 8-M20 |

| 200 | 260 | 175 | 60.6 | 202.5 | F10 | 4-ø12 | 125 | 102 | 295 | 295 | 8-M20 | 12-M20 |

| 250 | 292 | 203 | 65.6 | 250.5 | F10 | 4-ø12 | 125 | 102 | 355 | 355 | 12-M20 | 12-M24 |

| 300 | 337 | 242 | 76.9 | 301.6 | F10 | 4-ø12 | 125 | 102 | 410 | 410 | 12-M20 | 12-M24 |

| 350 | 368 | 267 | 76.5 | 333.3 | F10 | 4-ø12 | 125 | 102 | 470 | 470 | 16-M20 | 16-M24 |

| 400 | 400 | 309 | 86.5 | 389.6 | F14 | 4-ø18 | 197 | 140 | 525 | 525 | 16-M24 | 16-M27 |

| 450 | 422 | 328 | 102 | 440.5 | F14 | 4.ø18 | 197 | 140 | 585 | 585 | 20-M24 | 20-M27 |

| 500 | 480 | 361 | 127 | 4916 | F14 | 4-ø18 | 197 | 140 | 650 | 650 | 20-M24 | 20-M30 |

| 600 | 562 | 459 | 152 | 592.5 | F14 | 4-ø18 | 197 | 140 | 770 | 770 | 20-M27 | 20-M33 |

| 700 | 624 | 520 | 163 | 695 | F25 | 8-ø18 | 300 | 254 | 840 | 840 | 24-M27 | 24-M33 |

| 750 | 660 | 539 | 167 | 745 | F25 | 8-ø 18 | 300 | 254 | 900 | 900 | 24-M30 | 24-M33 |

| 800 | 672 | 591 | 188 | 795 | F25 | 8-ø18 | 300 | 254 | 950 | 950 | 24-M30 | 24-M36 |

| 900 | 720 | 656 | 203 | 865 | F25 | 8-ø18 | 300 | 254 | 1050 | 1050 | 28-M30 | 28-M36 |

| 1000 | 800 | 721 | 216 | 965 | F25 | 8-ø18 | 300 | 254 | 1160 | 1170 | 28-M33 | 28-M39 |

| 1200 | 941 | 864 | 276 | 1180 | F30 | 8-ø22 | 350 | 298 | 1380 | 1390 | 32-M36 | 32-M45 |

WESDOM Advantages

1.WESDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each wesdom product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All wesdom products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WESDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WESDOM has always been noticed all over the world, and trust comes from quality.

6. WESDOM has a strict quality control system

WESDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Advantages of the lug butterfly valve:

1. The thickness of valve body wall is up to standard

The valve body wall thickness meets the requirement of GB 26640, the thickness is up to the standard, and the pressure strength is guaranteed.

2. Valve body/valve plate is made of QT450-10 material

Valve body valve plate is made of qt450-10 material with spheroidization rate above grade 3, tensile strength of 450Mpa and elongation of >10%.

3. Good sealing and long service life of valve seat

The valve seat is made of imported rubber material, with more than 50% rubber content; Elongation at break greater than 350%, valve sealing reliable, long life.

4. Soft back with wide side seat

Soft backrest wide side valve seat, is advantageous to the valve installation, in the pipeline and flange boss contact surface is wide, sealing performance is reliable. Life is longer than a hard back and easy to remove and replace.

5. No pin structure to avoid corrosion

Butterfly plate and valve shaft adopt through shaft without pin structure to avoid leakage caused by hole mounting pin and accelerated corrosion caused by coating damage.

6. Valve body is sprayed with Aksu epoxy powerd

The valve body is sprayed with world-renowned Aksu epoxy resin powder, which has stronger adhesion and better environmental tolerance after melting and curing.

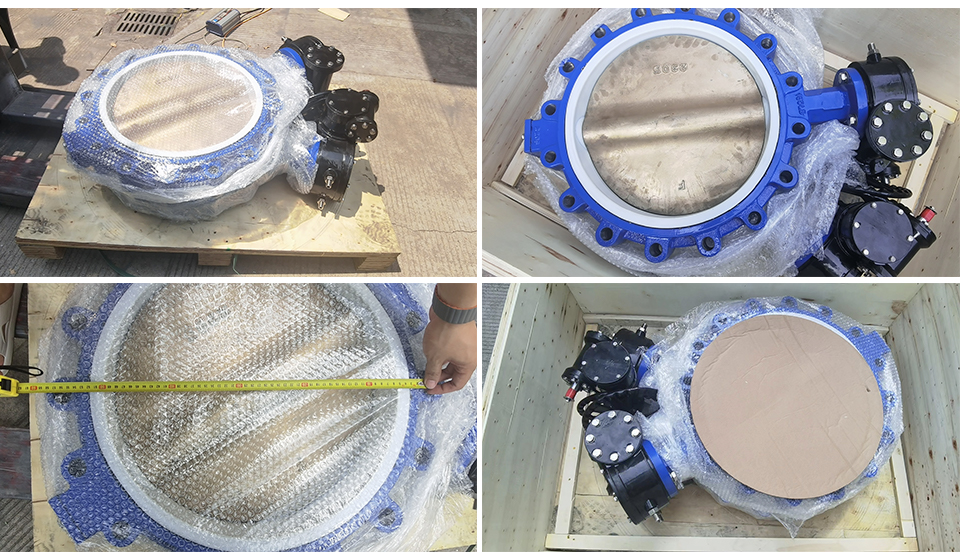

Case:

Tanzania Water Project

Main products: Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client feedback:

The customer sent us the installation pictures of the WESDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WESDOM;

Project pictures:

Application:

Some of the common applications of lug butterfly valves include:

1. HVAC Systems:

Lug butterfly valves are used in heating, ventilation, and air conditioning (HVAC) systems for controlling the flow of air and water. They are commonly used in applications such as cooling towers, air handling units, and heat exchangers.

2. Water Treatment Systems:

Lug butterfly valves are widely used in water treatment systems for controlling the flow of water and other fluids. They are commonly used in applications such as water distribution systems, water treatment plants, and pumping stations.

3. Chemical Processing:

Lug butterfly valves are used in chemical processing plants for controlling the flow of chemicals and other fluids. They are commonly used in applications such as mixing tanks, reactors, and distillation columns.

4. Food and Beverage Processing:

Lug butterfly valves are used in food and beverage processing plants for controlling the flow of liquids and gases. They are commonly used in applications such as fermentation tanks, bottling lines, and storage tanks.

5. Petrochemical Industry:

Lug butterfly valves are commonly used in the petrochemical industry for controlling the flow of liquids and gases. They are used in applications such as oil and gas pipelines, refineries, and storage tanks.

Please fill in your procurement needs and contact information