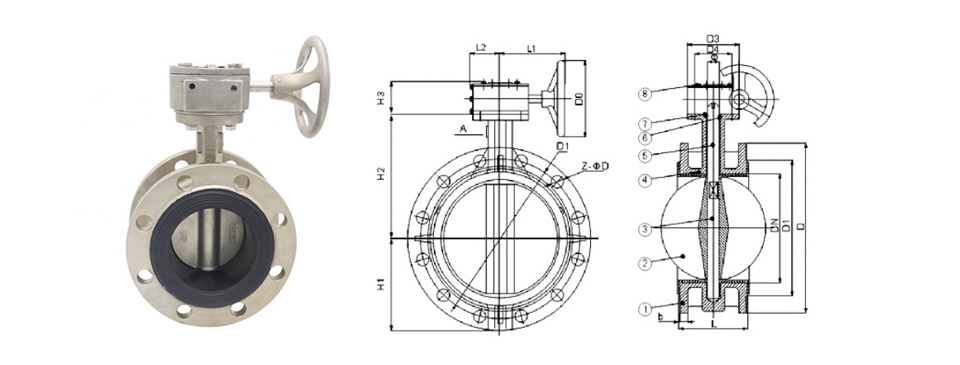

Stainless steel flanged butterfly valve

Features:

Size: 2”~40”

Pressure Rating: PN10, PN16, CL150, JIS 5K/10K

Material: SS304, SS316

Design Standard: EN 593, MSS SP67, API 609, BS5155

Inspection Standard: API 598, ISO 5208, EN 12266

Application medium: water, oil and gas

Application Temperature: -10 °C to 150°C

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is stainless steel butterfly valve?

A stainless steel butterfly valve is a type of valve that is made of stainless steel and consists of a circular disc or vane that is mounted on a shaft. The disc can be rotated to control the flow of fluid or gas through the valve. The valve is called a butterfly valve because the shape of the disc resembles the wings of a butterfly.

Stainless steel butterfly valves are commonly used in industries such as food and beverage, pharmaceutical, and chemical processing, where high levels of hygiene and corrosion resistance are required. Stainless steel is an ideal material for these applications because it is resistant to corrosion and can withstand high temperatures and pressures.

Stainless steel butterfly valves can be operated manually, electrically, or pneumatically, depending on the application. They are known for their quick response times, low pressure drop, and ease of installation and maintenance, which makes them a popular choice for many industries.

|

DN |

L |

L1 |

D |

D1 |

D3 |

D4 |

H1 |

H2 |

H3 |

b |

Z-ød |

|||

|

PN10 |

PN16 |

PN10 |

PN16 |

PN10 |

PN16 |

|||||||||

|

50 |

108 |

160 |

165 |

1665 |

125 |

125 |

70 |

50 |

83 |

130 |

60 |

18 |

4–18 |

4–18 |

|

65 |

112 |

160 |

186 |

185 |

145 |

145 |

70 |

50 |

93 |

140 |

60 |

18 |

4–18 |

4–18 |

|

80 |

114 |

160 |

200 |

200 |

160 |

160 |

70 |

50 |

100 |

150 |

60 |

20 |

8–18 |

8–18 |

|

100 |

127 |

160 |

220 |

220 |

180 |

180 |

90 |

70 |

110 |

165 |

60 |

20 |

8–18 |

8–18 |

|

125 |

140 |

160 |

250 |

250 |

210 |

210 |

90 |

70 |

123 |

180 |

60 |

22 |

8–18 |

8–18 |

|

150 |

140 |

160 |

285 |

285 |

240 |

240 |

90 |

70 |

143 |

200 |

60 |

22 |

8–22 |

8–22 |

|

200 |

152 |

210 |

340 |

340 |

295 |

295 |

125 |

125 |

171 |

230 |

72 |

24 |

8–22 |

12–22 |

|

250 |

165 |

210 |

390 |

405 |

350 |

355 |

125 |

125 |

203 |

270 |

72 |

24 |

12–22 |

12–26 |

|

300 |

178 |

210 |

440 |

460 |

400 |

410 |

150 |

140 |

230 |

320 |

75 |

26 |

12–22 |

12–26 |

|

350 |

190 |

210 |

50 |

520 |

460 |

470 |

150 |

140 |

260 |

350 |

75 |

26 |

16–22 |

16–26 |

|

400 |

216 |

320 |

565 |

580 |

515 |

525 |

175 |

165 |

300 |

390 |

126 |

28 |

16–26 |

16–30 |

|

450 |

222 |

320 |

615 |

640 |

565 |

585 |

175 |

165 |

335 |

428 |

126 |

30 |

20–26 |

20–30 |

|

500 |

229 |

320 |

670 |

715 |

620 |

650 |

210 |

254 |

373 |

450 |

126 |

32 |

20–26 |

20–33 |

|

600 |

267 |

340 |

780 |

840 |

725 |

770 |

210 |

254 |

430 |

520 |

127 |

34 |

20–30 |

20–36 |

|

700 |

292 |

380 |

895 |

910 |

840 |

840 |

300 |

254 |

470 |

600 |

167 |

36 |

24–30 |

24–36 |

|

800 |

318 |

380 |

1015 |

1025 |

950 |

950 |

300 |

254 |

523 |

662 |

167 |

36 |

24–30 |

24–39 |

|

900 |

330 |

400 |

1115 |

1125 |

1050 |

1050 |

300 |

254 |

589 |

710 |

193 |

40 |

28–33 |

28–39 |

|

1000 |

410 |

400 |

1230 |

1255 |

116 |

1170 |

300 |

254 |

656 |

780 |

193 |

42 |

28–36 |

28–42 |

|

1200 |

471 |

440 |

1405 |

1485 |

1340 |

1390 |

300 |

254 |

732 |

840 |

205 |

46 |

32–37 |

32–49 |

|

1400 |

530 |

440 |

1630 |

1685 |

1560 |

1590 |

300 |

254 |

840 |

905 |

212 |

50 |

36–37 |

36–49 |

WESDOM Advantages

1.WESDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each wesdom product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All wesdom products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WESDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WESDOM has always been noticed all over the world, and trust comes from quality.

6. WESDOM has a strict quality control system

WESDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Standard Test :

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature. It ensures the correct operation of the valve / actuator assembly with accessories such as solenoid valve, limit switches, air filter regulator etc.

Special Test: On request, any other test can be carried out according to special instruction by client.

Advantages of stainless steel butterfly valve!

1. Corrosion resistance

Stainless steel is highly resistant to corrosion, making it ideal for use in harsh environments where other materials may corrode or degrade.

2. Hygiene

Stainless steel is easy to clean and sanitize, making it suitable for applications in the food and beverage, pharmaceutical, and other industries where hygiene is critical.

3. Durability

Stainless steel is a strong and durable material that can withstand high temperatures and pressures, making it suitable for use in a wide range of applications.

4. Quick response time

Butterfly valves can be operated very quickly, which makes them suitable for applications where rapid response is required.

5. Easy to install and maintain

Butterfly valves are relatively easy to install and maintain, which can help to reduce downtime and maintenance costs.

6. Versatility

Stainless steel butterfly valves are available in a range of sizes and can be used for a variety of applications, from small-scale residential plumbing to large-scale industrial processes.

Case:

Pakistan Sewage Treatment Plant Project

Main products: Flanged Butterfly Valves and Gate Valves

This case is an old customer from Pakistan. Because he has purchased valve products from WESDOM many times, he has very high trust and evaluation on WESDOM. He needs a lot of butterfly valves and gate valve products in the sewage treatment plant project which he is responsible for. They sent the requirements to the businessman of WESDOM's international trade department without hesitation. Of course, WESDOM still returns this old customer in Pakistan with high-quality products and preferential prices;

After that, the customer also sent us the installation pictures of the WESDOM product in the working condition project, and feedback that the quality is still very good, and will maintain a long-term cooperative relationship with WESDOM;

Project pictures:

Application:

Stainless steel butterfly valves are commonly used in various industrial and commercial applications where reliable and efficient flow control is required in corrosive or high-temperature environments. Some of the common applications of stainless steel butterfly valves include:

1. Food and Beverage Processing:

Stainless steel butterfly valves are used in food and beverage processing plants for controlling the flow of liquids and gases. They are commonly used in applications such as fermentation tanks, bottling lines, and storage tanks.

2. Chemical Processing:

Stainless steel butterfly valves are used in chemical processing plants for controlling the flow of chemicals and other fluids. They are commonly used in applications such as mixing tanks, reactors, and distillation columns.

3. Pharmaceutical Industry:

Stainless steel butterfly valves are used in the pharmaceutical industry for controlling the flow of liquids and gases. They are used in drug manufacturing, sterile processing, and research and development applications.

4. Oil and Gas Industry:

Stainless steel butterfly valves are commonly used in the oil and gas industry for controlling the flow of liquids and gases. They are used in applications such as pipelines, refineries, and storage tanks.

5. Water Treatment Systems:

Stainless steel butterfly valves are widely used in water treatment systems to control water flow and other fluids. They are commonly used in applications such as water distribution systems, water treatment plants, and pumping stations.

Please fill in your procurement needs and contact information