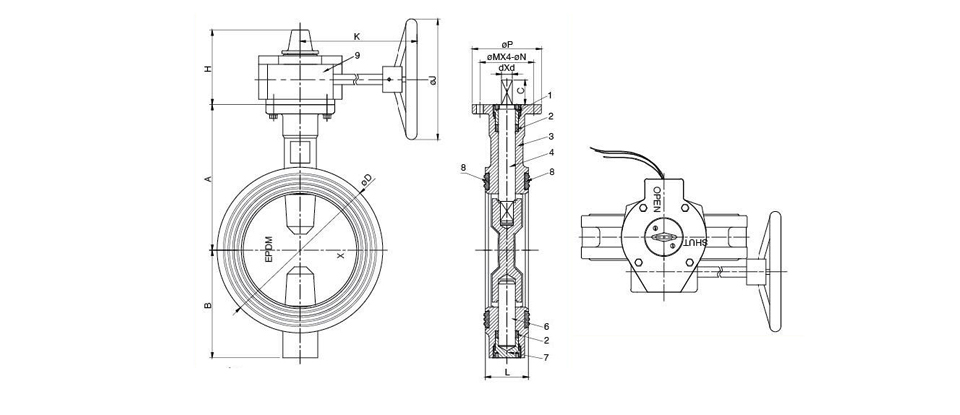

Wafer butterfly valve ULC approved

Features:

Size: 2", 2½", 3", 4", 5", 6", 8", 10", 12"

Pressure Rating: 300psi

Approvals: UL, ULC, FM

Design Standard: API 609

Top Flange Standard: ISO5211 / 1

Disc: EPDM Rubber Encapsulated Ductile Iron Wedge

Application: Indoor & Outdoor Use, Fire inflow water, drain pipe, high-rising building fire fighting system, industrial factory building fire protection system

We're here to help:

Easy ways to get the answers you need.

Parameter:

ULC butterfly valve refers to a type of butterfly valve that meets the safety and performance standards of the Underwriters Laboratories of Canada (ULC), which is a certification and testing organization accredited by the Standards Council of Canada.

A ULC butterfly valve is designed to provide reliable and safe operation. It is tested and evaluated according to ULC standards to ensure it meets the highest safety and performance requirements. These valves are commonly used in various industries and applications, including HVAC, water treatment, chemical processing, and oil and gas.

ULC butterfly valves are typically made of high-quality materials like stainless steel, carbon steel, or ductile iron. They are available in various sizes and configurations to meet different application requirements. They operate by rotating a disc inside the valve body to control the flow of fluid. The ULC certification confirms that an independent third-party organization has tested and evaluated the valve to ensure it meets the highest safety and quality standards.

WESDOM Advantages

1.WESDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each wesdom product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All wesdom products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WESDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WESDOM has always been noticed all over the world, and trust comes from quality.

6. WESDOM has a strict quality control system

WESDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

The advantages of ULC butterfly valves are:

1. High level of safety:

ULC butterfly valves meet strict safety standards and are tested to ensure they can withstand various conditions, making them a reliable and safe choice for many applications.

2. Versatile:

ULC butterfly valves are available in a range of sizes and configurations, making them suitable for different applications.

3. Easy to install and maintain:

Butterfly valves are relatively easy to install and maintain, which can save time and money in the long run.

4. Cost-effective:

ULC butterfly valves are generally more cost-effective than other types of valves, making them a popular choice for many industries.

5. Good flow control:

Butterfly valves offer good flow control, with a low-pressure drop and high flow capacity.

6. Durable:

ULC butterfly valves are typically made of high-quality materials, which can withstand harsh conditions and provide long-lasting performance.

7.Energy efficient:

The low-pressure drop and high flow capacity of butterfly valves make them energy-efficient, reducing operating costs and environmental impact.

Pressure:

In all types of butterfly valves, the disk has an embedded stem so that it can be rotated, typically with a wheel. The disk can then be turned with regards to this central stem, making it face along or against the flow of liquid. Because of this, the stem is always available in the middle of the opening, no matter what angle the disk itself is in. The pressure in the liquid then receives a drop whenever it passes through the UL FM butterfly valves, which gives it a secondary purpose in liquid regulation.

Installation procedures:

The different types of butterfly valves typically have one major difference: the way they are installed. A wafer butterfly valve uses a set of nuts and bolts to connect the valve to two flanges. This system uses the same nuts and bolts to connect both flanges to the UL/FM butterfly valves. Although this is the most common type of installation, the wafer butterfly valve poses one disadvantage, because it makes maintenance a bit extensive. Instead of simply disconnecting one side of the pipes and using the valve to close the other side while maintenance is done, the installation will require that the whole liquid flow be stopped at an earlier valve for one side of the pipes to be checked.

Specifications:

The UL FM approved butterfly valves have a working temperature of -20 to +110 degrees Celsius (with an equivalent of -4 to +230 in Fahrenheit). They follow a face to face standard of ASME B16.1, and have a nominal pressure of 300 PSI, equivalent to 21 bar. The top coupling flange of all the butterfly valves is of ISO 5211. The whole butterfly valve is made according to certified and standardized designs. It is design according to the API 609 standard, while it is tested according to the API 598 standard.

The UL FM approved butterfly valves also come in different sizes to make sure that every user gets the perfect fit with existing piping systems. This is to make sure that safety is of the highest priority. Along with having different sizes, the UL/FM butterfly valves are checked and certified to uphold this priority on safety. This is to ensure that wherever the wafer butterfly valves are used, there will be no safety issues whatsoever.

Application:

ULC butterfly valves are designed and certified to meet the standards set by the Underwriters Laboratories of Canada (ULC). These valves are widely used in various industries for regulating the flow of fluids and gases in fire protection systems. Some common applications of ULC butterfly valves include:

1. Fire protection systems:

ULC butterfly valves are commonly used in fire protection systems for controlling the flow of water and other fire suppression agents. These valves are designed to provide reliable performance even under extreme conditions, such as high temperatures and pressures.

2. HVAC systems:

ULC butterfly valves are also used in heating, ventilation, and air conditioning (HVAC) systems for regulating the flow of air and controlling temperature and humidity. These valves are designed to provide reliable performance and tight sealing, which is essential for maintaining a comfortable and safe indoor environment.

3. Water treatment:

ULC butterfly valves are used in water treatment plants for regulating the flow of water, controlling pressure, and isolating different parts of the system. These valves are designed to provide reliable performance, even in harsh environments, such as those found in wastewater treatment plants.

Please fill in your procurement needs and contact information