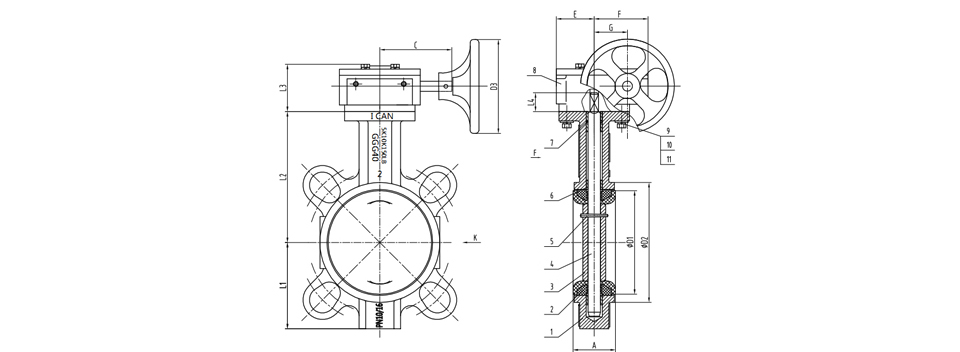

Worm gear operated butterfly valve

Features:

Size: 2~8"(DN50~DN200)

Pressure Rating: PN10, PN16, JIS5K,JIS10K,JIS16K

Material: Cast Iron, Ductile Iron, WCB , Stainless Steel, Bronze

Design Standard: BS 5155,EN593, API 609, JIS B2064

Inspection Standard: BS 6755, EN12266, API 598, FIS B2003-87, GB/T 13927-92,M

Application medium: water, oil, gas

Operate: Manual, Worm gear, Pneumatic, Electric-Motorized

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is wafer butterfly valve?

A wafer butterfly valve is a type of butterfly valve that is designed to be installed between two flanges using bolts or studs. This type of valve is called a "wafer" valve because it is very thin and has the same face-to-face dimensions as the flanges it is mounted between, making it more compact and lighter in weight than other types of valves.

Wafer butterfly valves consist of a disc that rotates around a shaft to control the flow of fluid in a pipeline. When the valve is closed, the disc is perpendicular to the flow, blocking the passage of fluid. When the valve is open, the disc rotates parallel to the flow, allowing fluid to pass through the valve.

Wafer butterfly valves are commonly used in limited space and weight applications, such as in HVAC systems, water treatment plants, and food and beverage processing industries. They are also used in applications requiring quick and easy installation and removal, such as in emergency shut-off systems.

| DN | D | D1 | MØ | L | A | B | N-Ø2 | f | F1 | F2 | F3 |

| 100 | 220 | 180 | M16 | 52 | 100 | 185 | 4-10 | 5 | 90 | 70 | 15.8 |

| 125 | 250 | 210 | M16 | 56 | 123 | 191 | 4-10 | 5 | 90 | 70 | 18.9 |

| 150 | 285 | 240 | M20 | 56 | 135 | 206 | 4-10 | 5 | 90 | 70 | 18.9 |

| 200 | 340 | 295 | M20 | 60 | 163 | 239 | 4-12 | 5 | 125 | 102 | 22.2 |

| 250 | 395 | 350 | M20 | 68 | 198 | 272 | 4-12 | 8 | 125 | 102 | 28.5 |

| 300 | 445 | 400 | M20 | 78 | 226 | 317 | 4-14 | 8 | 150 | 125 | 31.6 |

| 350 | 505 | 460 | M20 | 78 | 265 | 333 | 4-14 | 8 | 150 | 125 | 31.6 |

| 400 | 565 | 515 | M24 | 88 | 290 | 362 | 4-18 | 10 | 210 | 140 | 33 |

WEIZIDOM Advantages

1.WEIZIDOMpatent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

Quality Control Process

Standards&Features:

Wafer butterfly valves offer several advantages over other types of valves, including:

1. Compact and Lightweight:

The wafer butterfly valve is thin and has the same face-to-face dimensions as the flanges it is mounted between, making it more compact and weightier than other valves. This makes it easier to install and saves space.

2. Easy to Install and Remove:

Wafer butterfly valves are easy to install and remove since they only require a few bolts or studs to hold them in place. This makes them ideal for emergency repairs or quick valve replacement.

3. Low Pressure Drop:

The streamlined design of the wafer butterfly valve results in a low pressure drop across the valve, reducing energy consumption and lowering operating costs.

4. Cost-Effective:

Wafer butterfly valves are cost-effective compared to other types of valves, making them ideal for use in applications where cost is a major consideration.

5. Versatile:

Wafer butterfly valves can be used in a wide range of applications, including HVAC systems, water treatment plants, and food and beverage processing industries, among others.

6.Easy to Operate:

Wafer butterfly valves are easy to operate since they require only a quarter-turn to open or close, making them ideal for applications requiring a frequent operation.

Case:

Tanzania Water Project

Main products: Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client feedback:

The customer sent us the installation pictures of the WEIZIDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WEIZIDOM;

Project pictures:

Application:

Application of wafer butterfly valve:

1. HVAC Systems:

Wafer butterfly valves are used in heating, ventilation, and air conditioning (HVAC) systems for controlling the flow of air and water. They are commonly used in applications such as cooling towers, air handling units, and heat exchangers.

2. Water Treatment Systems:

Wafer butterfly valves are widely used in water treatment systems for controlling the flow of water and other fluids. They are commonly used in applications such as water distribution systems, water treatment plants, and pumping stations.

3. Chemical Processing:

Wafer butterfly valves are used in chemical processing plants for controlling the flow of chemicals and other fluids. They are commonly used in applications such as mixing tanks, reactors, and distillation columns.

4. Food and Beverage Processing:

Wafer butterfly valves are used in food and beverage processing plants for controlling the flow of liquids and gases. They are commonly used in applications such as fermentation tanks, bottling lines, and storage tanks.

5. Oil and Gas Industry:

Wafer butterfly valves are commonly used in the oil and gas industry for controlling the flow of liquids and gases. They are used in applications such as pipelines, refineries, and storage tanks.

Please fill in your procurement needs and contact information

.jpg)

.jpg)