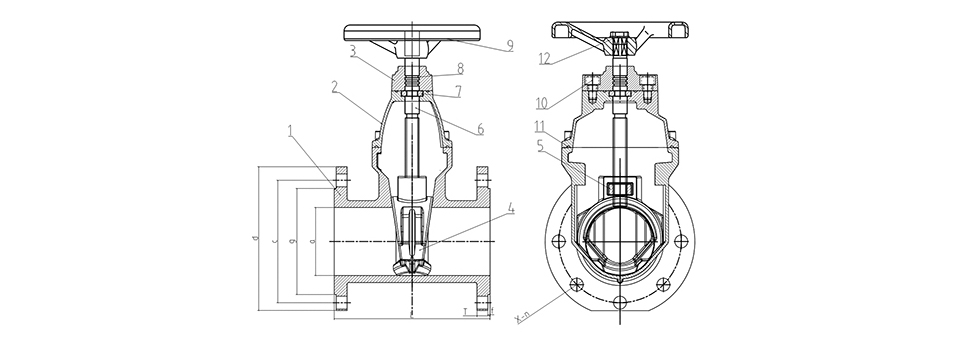

DIN F5 resilient seated gate valve

Features:

Size: DN50-DN300

Pressure Rating: PN16/PN25

Material: Ductile Iron

Design Standard: DIN3352 F5, EN1171

Inspection Standard: DIN3352 F5, EN1171

Application medium: Drinking water、sewage、seawater、irrigation,or other neutral liquid

Application Temperature: -40°C~150°C

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is a resilient seated gate valve?

DIN F5 resilient seated gate valve is a type of gate valve that conforms to the German DIN standard. DIN F5 refers to the valve's face-to-face dimension, which is 200mm. The valve is designed with a resilient seat, which is typically made of materials such as rubber or EPDM.

The resilient seat of the valve provides a tight seal, preventing leaks and minimizing the risk of contamination. The valve's gate is designed to move up and down to control the flow of fluids in a pipeline. When the valve is fully open, the gate is lifted completely out of the flow path, allowing for maximum flow capacity.

DIN F5 resilient seated gate valves are commonly used in water treatment plants, sewage systems, and industrial processes. They are known for their reliability, durability, and ease of use, making them a popular choice for many industries.

|

DN |

L -mm |

d-mm |

c-mm |

x-n |

T-mm |

f-mm |

g-mm |

working pressure |

|||

|

PN10 |

PN16 |

PN10 |

PN16 |

10kg |

16kg |

||||||

|

50 |

250 |

165 |

165 |

125 |

125 |

4-ø19 |

19 |

3 |

99 |

PN10/16 |

|

|

65 |

270 |

185 |

185 |

145 |

145 |

4-ø19 |

19 |

3 |

118 |

||

|

80 |

280 |

200 |

200 |

160 |

160 |

8-ø19 |

19 |

3 |

132 |

||

|

100 |

300 |

220 |

220 |

180 |

180 |

8-ø19 |

19 |

3 |

156 |

||

|

125 |

325 |

250 |

250 |

210 |

210 |

8-ø19 |

19 |

3 |

184 |

||

|

150 |

350 |

285 |

285 |

240 |

240 |

8-ø23 |

19 |

3 |

211 |

||

|

200 |

400 |

340 |

340 |

295 |

295 |

8-ø23 |

12-ø23 |

20 |

3 |

266 |

|

|

250 |

450 |

395 |

405 |

350 |

355 |

12-ø23 |

12-ø26 |

22 |

3 |

319 |

|

|

300 |

500 |

445 |

460 |

400 |

410 |

12-ø23 |

12-ø26 |

24.5 |

4 |

370 |

|

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

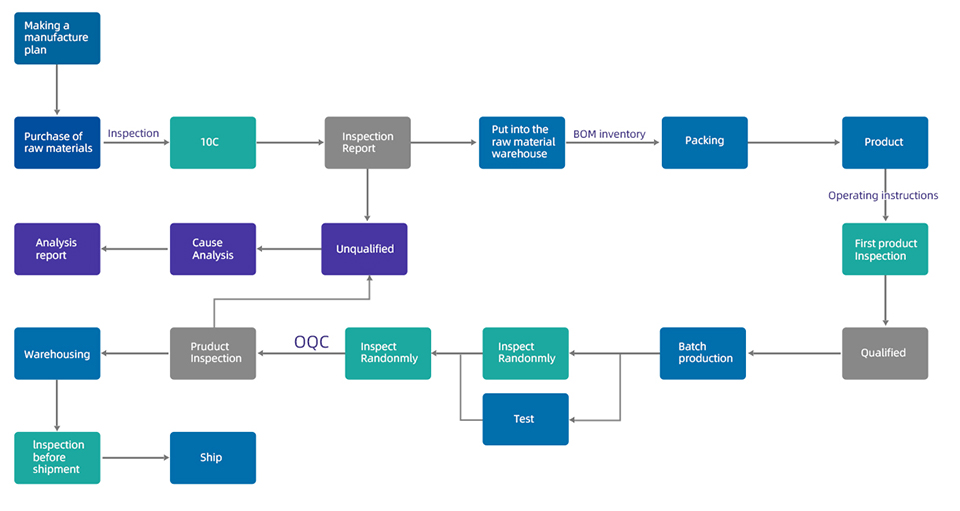

6. WEIZIDOM has a strict quality control system

Quality Control Process

Standards&Features:

|

Design standard |

|

|

Flange drilling standard |

EN1092-2 PN10/PN16 |

|

Face to face standard |

EN558-1 Series 15 |

|

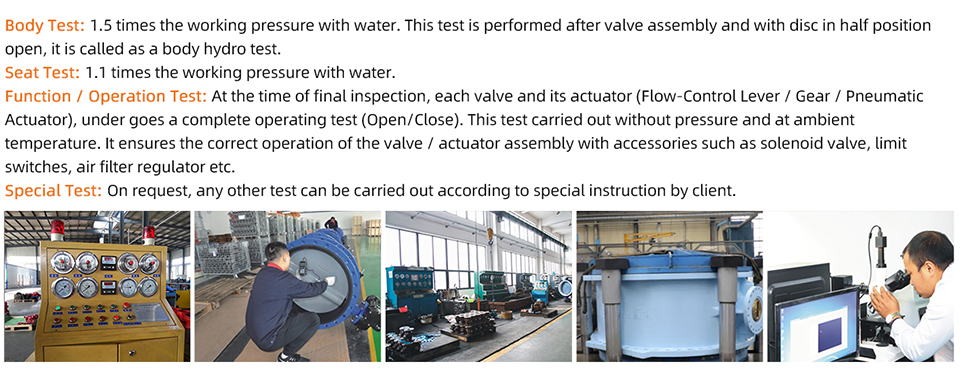

Hydraulic test standard |

EN1074-1 and 2 /EN12266 |

|

|

Seat:1.1*PN(in bar), Body:1.5*PN(in bar) |

Advantages of DIN F5 resilient gate valve:

1. Flat base seat

Traditional gate valves used to have foreign objects such as stone, wood, cement, paper, and other debris in the notch of the valve bottom, then cause water leakage when the valve can not be close tightly. A soft seal gate valve is designed with a flat base, which is in the pipe’s same level, then no more foreign objects fill in, easily to be free-flowing.

2. Overall rubber coating

Using high-quality rubber to overall coat the valve disc both inside and outside, with domestically leading rubber vulcanized technology, the valve is able to maintain accurate geometry size. What’s more, high adhesion between the rubber and valve disc makes the rubber steadily stick with good elastic memory.

3. Corrosion resistance

The valve body is coated with epoxy resin powder, which can prevent the valve from corrosion and rusting, and the valve can be used in the wastewater system. Difficult to break, traditional gate valves are used to cause fracture because of the hit or collision from other objects. The new valve body material is ductile iron, which reduces the fracture situation remarkably.

4. Three “O” ring seals

The stem with a three “O” ring seal design can reduce friction switch, significantly reducing water leakage. Besides, we can replace the valves without stopping the water construction.

5. Helping to drink

Due to the internal body to non-toxic epoxy resin coating, the Inner and outer surfaces of the shutter is completely covered with rubber so it will not appear rust or corrosion, ensure water is available to drink.

6. Body Casting

The body uses precision casting precise geometry, making it possible to ensure the valve seal without any other finishing to the inner of the valve.

7. Lightweight

Body with a ductile cast made, lighter in weight than the conventional valve, about 20% to 30%, easy installation, and maintenance.

Technical Parameters

|

Nominal diameter(mm) |

50~300 |

50~300 |

|

|

Nominal pressure(Mpa) |

1.0 |

1.6 |

|

|

Testing pressure |

Shell(Mpa) |

1.5 |

2.4 |

|

Seal(Mpa) |

1.1 |

1.76 |

|

|

Suitable temperature |

0°C~80°C |

||

|

Suitable medium |

Drinking water、sewage、seawater、irrigation,or other neutral liquid. |

||

Case:

Tanzania Water Project

Main products: Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Customer needs: water project treatment

Client feedback:

The customer sent us the installation pictures of the WEIZIDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WEIZIDOM;

Project pictures:

Application:

DIN F5 resilient seated gate valve is a type of gate valve that is widely used in various industries for controlling the flow of fluids such as water, steam, and gas. The valve has a resilient seat that provides a tight seal even in low-pressure applications. Here are some of the applications of DIN F5 resilient seated gate valve:

1. Water treatment plants:

DIN F5 resilient seated gate valves are commonly used in water treatment plants for regulating the flow of water. These valves provide a tight seal and are resistant to corrosion, making them ideal for use in harsh conditions.

2. HVAC systems:

DIN F5 resilient seated gate valves are used in HVAC systems for regulating the flow of water and other fluids. These valves are preferred due to their high flow rates and excellent sealing capabilities.

3. Industrial applications:

DIN F5 resilient seated gate valves are widely used in various industrial applications such as chemical plants, oil refineries, and power plants. These valves are designed to handle high-pressure and high-temperature applications, making them ideal for use in these industries.

4. Irrigation systems:

DIN F5 resilient seated gate valves are commonly used in irrigation systems for regulating the flow of water. These valves are designed to handle high volumes of water and are resistant to corrosion, making them ideal for use in agricultural applications.

Please fill in your procurement needs and contact information