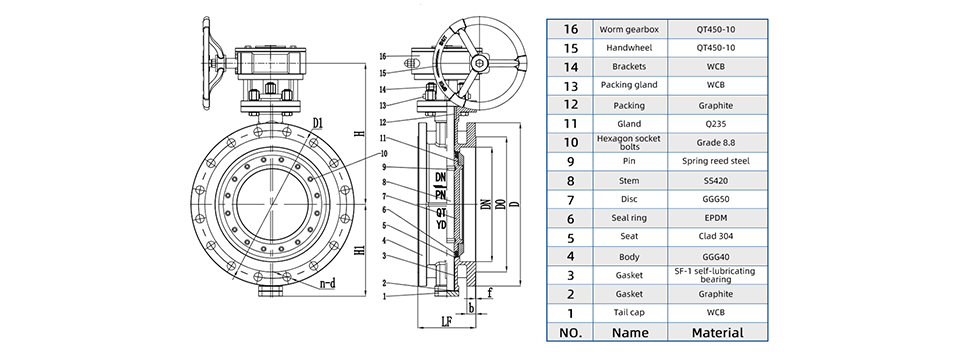

DN2000 Double eccentric butterfly valve

Features:

Size: DN150-DN3200

Pressure Rating: PN16/PN25

Material: Ductile Iron

Design Standard: DIN3352 F4, LIGHT TYPE

Inspection Standard: EN12266

Application medium: Drinking water, sewage, seawater, irrigation or other neutral liquid

Application Temperature: -40°C~150°C

We're here to help:

Easy ways to get the answers you need.

Parameter:

Brief introduction of double eccentric butterfly valve:

D342X, D942X, D342Xs, and D942Xs type rubber sealed butterfly valve adopts double eccentric structure, absorbs the structure and characteristics of similar foreign products, overcomes the defects in the use of the original product, and makes its life more durable and more reliable sealing. Double eccentric butterfly valve is suitable for various pipelines, specially installed in the outlet of the circulating water pump, for cutting off or regulating the flow of the medium, and can inhibit the impact effect produced when the pump starts and stops, without being affected by the flow direction of the medium.

| DN | Main ouler size | Main connection size | |||||||||||||||

| 0.6Mpa | 1.0Mpa | 1.6Mpa | |||||||||||||||

| L | H | H1 | A | B | D | D1 | D2 | n-d | D | D1 | D2 | n-d | D | D1 | D2 | n-d | |

| 50 | 108 | 825 | 306 | 80 | 80 | 140 | 110 | 88 | 4-14 | 165 | 125 | 99 | 4-18 | 165 | 125 | 99 | 4-18 |

| 65 | 112 | 925 | 321 | 80 | 80 | 160 | 130 | 108 | 4-14 | 195 | 145 | 118 | 4-18 | 185 | 145 | 118 | 4-18 |

| 80 | 114 | 100 | 346 | 80 | 80 | 190 | 150 | 124 | 4-18 | 200 | 160 | 132 | 8-18 | 200 | 160 | 132 | 8-18 |

| 100 | 127 | 110 | 37 | 95 | 95 | 210 | 170 | 144 | 4-18 | 220 | 180 | 156 | 8-18 | 220 | 180 | 156 | 8-18 |

| 125 | 140 | 125 | 411 | 95 | 95 | 240 | 200 | 174 | 8-18 | 250 | 210 | 184 | 8-18 | 250 | 210 | 184 | 8-18 |

| 150 | 140 | 1425 | 447 | 95 | 95 | 265 | 225 | 199 | 8-18 | 285 | 240 | 211 | 8-22 | 2B5 | 240 | 211 | 8-2 |

| 200 | 152 | 170 | 607 | 190 | 300 | 320 | 280 | 254 | 8-18 | 340 | 295 | 266 | 8-22 | 340 | 296 | 266 | 12-22 |

| 260 | 165 | 1925 | 688 | 190 | 308 | 376 | 335 | 309 | 12-18 | 396 | 350 | 319 | 12-22 | 405 | 355 | 319 | 12-26 |

| 300 | 178 | 2225 | 742 | 190 | 308 | 440 | 395 | 363 | 12-22 | 445 | 400 | 370 | 12-22 | 480 | 410 | 370 | 12-26 |

| 350 | 190 | 2525 | 797 | 190 | 30B | 490 | 445 | 413 | 12-22 | 505 | 460 | 429 | 16-22 | 520 | 470 | 429 | 16-26 |

| 400 | 216 | 2825 | 930 | 270 | 486 | 540 | 495 | 463 | 16-22 | 565 | 515 | 480 | 16-26 | 580 | 525 | 480 | 16-30 |

| 450 | 222 | 3075 | 975 | 270 | 486 | 566 | 550 | 518 | 16-22 | 615 | 565 | 530 | 20-26 | 640 | 585 | 548 | 20-30 |

| 500 | 229 | 335 | 1065 | 270 | 486 | 645 | 600 | 568 | 20-22 | 670 | 620 | 6R2 | 20-26 | 715 | 650 | 609 | 20-33 |

| 600 | 267 | 390 | 1225 | 457 | 625 | 755 | 705 | 667 | 20-26 | 780 | 725 | 682 | 20-30 | 840 | 770 | 720 | 20-36 |

| 700 | 292 | 4475 | 1343 | 457 | 625 | 860 | 810 | 772 | 24-26 | 895 | 840 | 794 | 24-30 | 910 | 840 | 794 | 24-36 |

| 800 | 318 | 5075 | 1436 | 457 | 625 | 975 | 920 | 878 | 24-30 | 1015 | 950 | 901 | 24-33 | 1025 | 950 | 901 | 24-39 |

| 900 | 330 | 5575 | 1616 | 598 | 853 | 1075 | 1020 | 978 | 24-30 | 115 | 1050 | 1001 | 28-33 | 1125 | 1050 | 1001 | 28-39 |

| 1000 | 410 | 615 | 1711 | 598 | 853 | 1175 | 1120 | 1078 | 28-30 | 1230 | 1160 | 1112 | 28-36 | 1255 | 1170 | 112 | 28-42 |

| 1200 | 470 | 7275 | 1971 | 598 | 853 | 1405 | 1340 | 1295 | 32-33 | 1455 | 1380 | 1328 | 32-39 | 1485 | 1380 | 1328 | 32-48 |

| 1400 | 530 | 8375 | 2218 | 860 | 1345 | 1630 | 1560 | 1510 | 36-36 | 1675 | 1590 | 1530 | 36 -42 | 16865 | 1590 | 1530 | 36-48 |

| 1600 | 600 | 957.5 | 2578 | 880 | 1345 | 1800 | 1760 | 1710 | 40-36 | 1915 | 1820 | 1750 | 40-48 | 1990 | 1820 | 1760 | 40-56 |

| 1800 | 670 | 1067.5 | 2689 | 880 | 1345 | 2045 | 1970 | 1918 | 44-39 | 2115 | 2020 | 1950 | 4448 | 2130 | 2020 | 1960 | 44-56 |

| 2000 | 760 | 1162.5 | 3022 | 952 | 1592 | 2265 | 2180 | 2125 | 48-42 | 2325 | 2230 | 2150 | 48-48 | 2345 | 2230 | 2150 | 48-82 |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

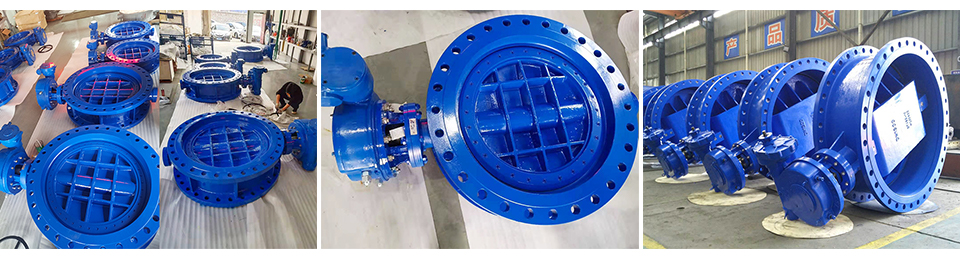

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

Quality Control Process

Standards&Features:

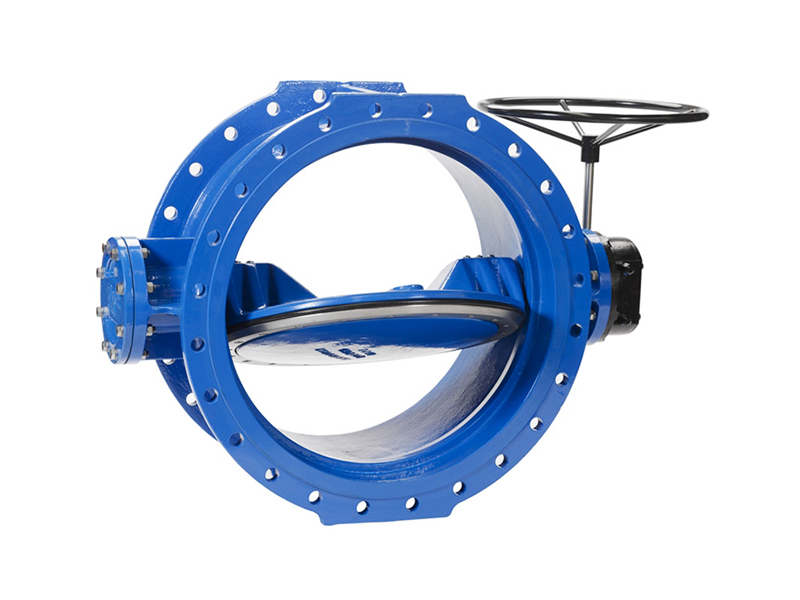

Double Eccentric Butterfly Valve description:

Flange butterfly valve, mounting between flanges PN10/PN16/A150, with gear box.

The range of WEIZIDOM valves can be used for overground installation, in valve chambers and buried systems.butterfly valves in a range of DN 150 to 2000 mm and PN 10, 16 and 25 bar have been designed to isolate the flow of fluid in:

①Potable water supply pipelines and treatment plants.

②Transportation of filtered and recycled water.

③Irrigation distribution networks.

④Water-pumping stations and hydroelectric plants.

⑤Reservoirs.

The range of WEIZIDOM valves can be used for overground installation, in valve chambers and buried systems. It includes a full range of operating accessories and actuators.

WEIZIDOM valves are installed all over the Asia,Africa continent, the Middle East and throughout Europe. They have justifiably acquired a faultless reputation for their durability, reliability and quality worldwide.

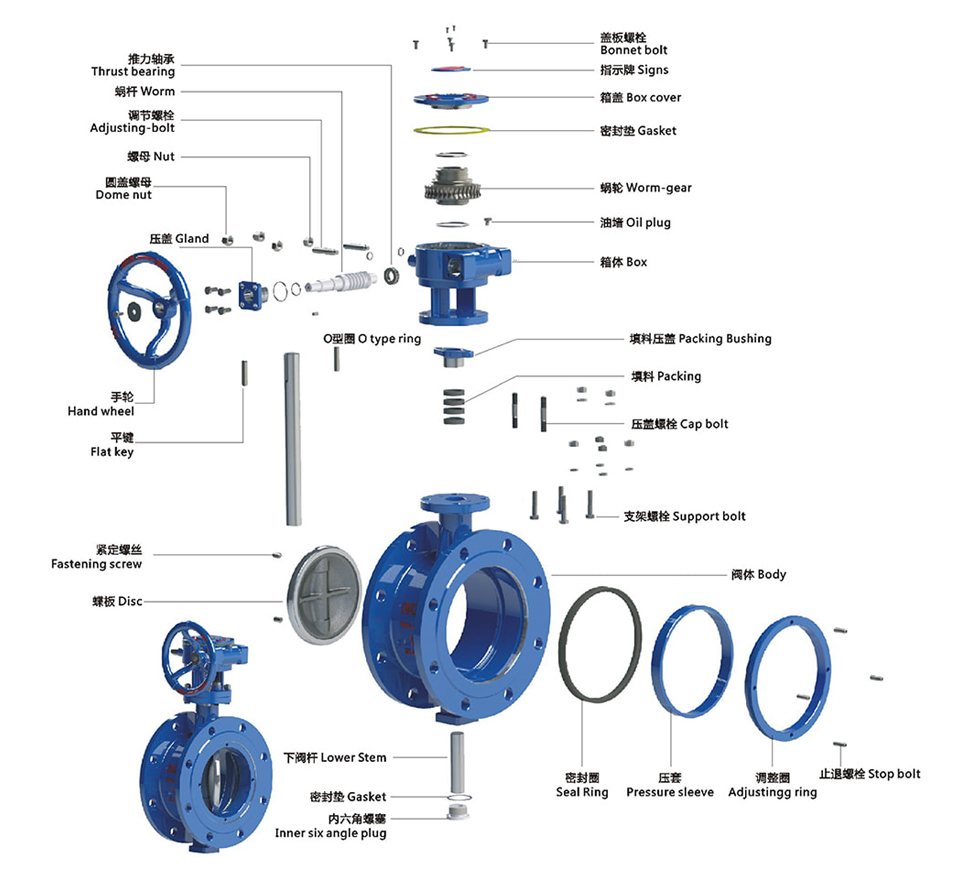

Double Eccentric Butterfly Valve characteristic:

①Body adopts integral casting technology, compact structure, small volume and light weight;

②Disc three ccentic mounting. When closed, disc expands outwards to achieve the best peripheral seal; When opened, disc and seal ring quickly separated, effectively prevent the seal ring wear;

③Sealing ring design is novel, simple and maintenance-free;

④Sealing ring form is multi-level metal hard seal,suitable for harsh working conditions;

⑤Due to the use of three eccentric structure, the operating torque is greatly reduced;

⑥The flow resistance is small, the rated flow coefficient is large, about 3 times that of the same caliber single-seat valve;

⑦Strong self-cleaning ability, long service life;

⑧Standard actuators (pneumatic piston and electric) are interchangeable.

Application:

A Double eccentric butterfly valves is a type of butterfly valve with a unique design that allows for a tighter seal and better performance in high-pressure and high-temperature applications. Some common applications of double eccentric butterfly valves include:

1. Oil and gas industry:

Double eccentric butterfly valves are commonly used in the oil and gas industry for regulating the flow of various fluids and gases, controlling pressure, and isolating different parts of the system.

2. Chemical processing:

Double eccentric butterfly valves are widely used in chemical processing industries for regulating the flow of various chemicals and fluids, controlling pressure, and isolating different parts of the system.

3. Power generation:

Double eccentric butterfly valves are used in power generation plants for regulating the flow of steam and gas, controlling pressure, and isolating different parts of the system.

4. Water treatment:

Double eccentric butterfly valves are used in water treatment plants for regulating the flow of water, controlling pressure, and isolating different parts of the system.

5. HVAC systems:

Double eccentric butterfly valves are also used in heating, ventilation, and air conditioning (HVAC) systems for regulating the flow of air and controlling temperature and humidity.

Please fill in your procurement needs and contact information