Flange butterfly valve

Features:

Size: 2”~54”

Pressure Rating: PN10, PN16, CL150

Material: Ductile Iron, WCB, Stainless Steel

Design Standard: BS 5155,EN593, API 609

Inspection Standard: EN12266, API 598,GB/T 13927-92

Application medium: Water, Sewage, Gas

Application Temperature: -10℃~150℃NBR0-70℃,EPDM0-120'℃,PTFE 0-150℃

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is a flanged butterfly valve?

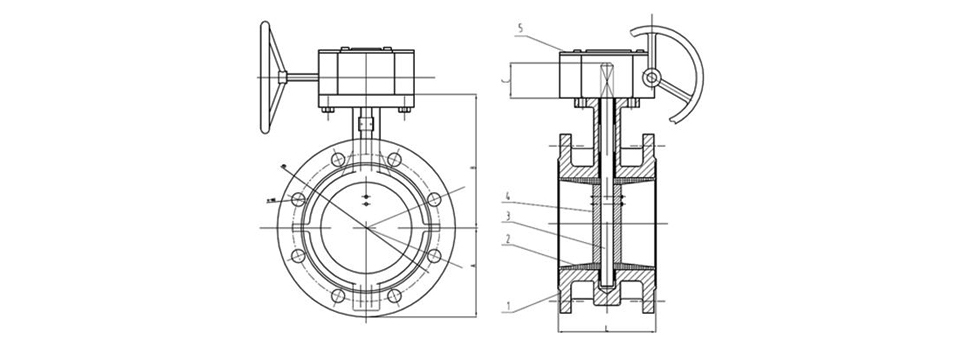

The flange butterfly valve is a type of butterfly valve, which refers to the butterfly valve connected to the flange connection. It is a very versatile valve, as well as another type of butterfly valve with a clamp connection. Compared with other types of valves, such as flange gate valve, flange globe valve and flange ball valve, flange butterfly valve structure is very simple, only flanged body, stem, disc, seat, driving device and so on a few parts.

In addition, compared to other valves, the flange butterfly valve has a smaller size and lighter weight, which is more suitable for making large diameter valve. With the improvement of manufacturing technology, the flange butterfly valve can be used in more and more working conditions, not only can be used to adjust the flow, but also can be used to cut the flow, gradually began to replace the flange gate valve, globe valve, ball valve and other applications in the pipeline system.

|

SIZE |

A |

B |

C |

L |

ANSI 150B |

DIN PN 10 |

DIN PN 16 |

JIS 10K |

Top Flange |

|||||||

|

mm |

in |

øK |

N-ød |

øK |

N-ød |

øK |

N-ød |

øK |

N-ød |

øD |

øD1 |

N-øG |

||||

|

65 |

2 1/2" |

72 |

136 |

32 |

112 |

139.7 |

4-ø19 |

145 |

4-ø18 |

145 |

4-ø18 |

140 |

4-ø19 |

77 |

57 |

4-ø7 |

|

80 |

3" |

88 |

146 |

32 |

114 |

152.4 |

4-ø19 |

160 |

8-ø18 |

160 |

8-ø18 |

150 |

8-ø19 |

65 |

50 |

4-ø7 |

|

100 |

4" |

96.5 |

158 |

32 |

127 |

190.5 |

4-ø19 |

180 |

8-ø18 |

180 |

8-ø18 |

175 |

8-ø19 |

90 |

70 |

4-ø10 |

|

125 |

5" |

115 |

179 |

32 |

140 |

215.9 |

8-ø19 |

210 |

8-ø18 |

210 |

8-ø18 |

210 |

8-ø23 |

90 |

70 |

4-ø10 |

|

150 |

6" |

126 |

197 |

32 |

140 |

241.3 |

8-ø22.4 |

240 |

8-ø22 |

240 |

8-ø22 |

240 |

8-ø23 |

90 |

70 |

4-ø10 |

|

200 |

8" |

161 |

230 |

45 |

152 |

298.4 |

8-ø22.4 |

295 |

8-ø22 |

295 |

12-ø22 |

290 |

12-ø23 |

115 |

89 |

4-ø14 |

|

250 |

10" |

199 |

271 |

45 |

165 |

361.9 |

12-ø25.4 |

350 |

12-ø22 |

355 |

12-ø26 |

355 |

12-ø25 |

115 |

89 |

4-ø14 |

|

300 |

12" |

215 |

305 |

45 |

178 |

431.8 |

12-ø25.4 |

400 |

12-ø22 |

410 |

12-ø26 |

400 |

16-ø25 |

140 |

108 |

4-ø14 |

|

350 |

14" |

261 |

350 |

45 |

190 |

476.2 |

12-ø28.4 |

460 |

16-ø22 |

470 |

16-ø26 |

445 |

16-ø25 |

140 |

108 |

4-ø14 |

|

400 |

16" |

290 |

381 |

51 |

216 |

539.7 |

16-ø28.4 |

515 |

16-ø26 |

525 |

16-ø30 |

510 |

16-ø27 |

197 |

159 |

4-ø21 |

|

450 |

18" |

307 |

392 |

51 |

222 |

577.8 |

16-ø31.8 |

565 |

20-ø26 |

585 |

20-ø30 |

565 |

20-ø27 |

197 |

159 |

4-ø21 |

|

500 |

20" |

340 |

441 |

57 |

229 |

635 |

20-ø31.8 |

620 |

20-ø26 |

650 |

20-ø33 |

620 |

20-ø27 |

197 |

159 |

4-ø21 |

|

600 |

24" |

396 |

500 |

70 |

267 |

749.3 |

20-ø35.1 |

725 |

20-ø30 |

770 |

20-ø36 |

730 |

24-ø33 |

276 |

216 |

4-ø22 |

|

700 |

28" |

496 |

567 |

66 |

292 |

863.6 |

28-ø35.1 |

840 |

24-ø30 |

840 |

24-ø36 |

840 |

24-ø33 |

300 |

254 |

8-ø18 |

|

800 |

32" |

543 |

641 |

66 |

318 |

977.9 |

28-ø41.1 |

950 |

24-ø33 |

950 |

24-ø39 |

950 |

28-ø33 |

300 |

254 |

8-ø18 |

|

900 |

36" |

584 |

692 |

118 |

330 |

1085.8 |

32-ø41.1 |

1050 |

28-ø33 |

1050 |

28-ø33 |

1050 |

28-ø33 |

300 |

254 |

8-ø18 |

|

1000 |

40" |

638 |

735 |

142 |

410 |

1200.2 |

38-ø41.1 |

1160 |

28-ø36 |

1170 |

28-ø42 |

1270 |

28-ø39 |

300 |

254 |

8-ø18 |

|

1200 |

48" |

763 |

917 |

150 |

470 |

1422.4 |

44-ø41.1 |

1380 |

32-ø39 |

1390 |

32-ø48 |

1380 |

32-ø39 |

350 |

298 |

8-ø22 |

|

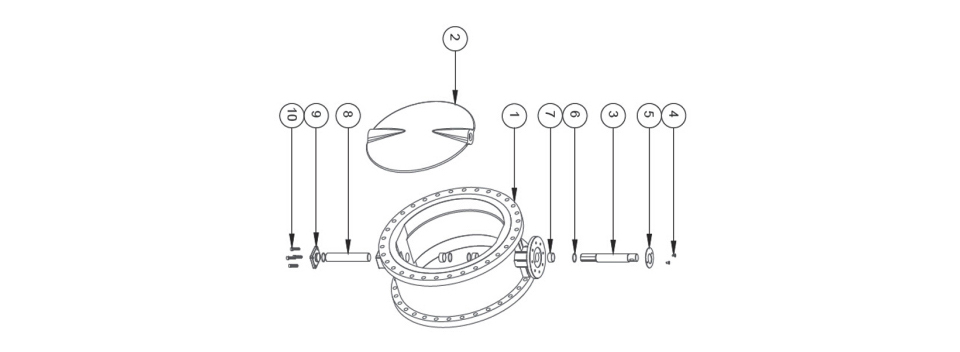

NO. |

Part name |

Material |

|

1 |

Body |

ASTM A536 65-45-12, WCB, CF8M |

|

2 |

Disc |

ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 |

|

3 |

Stem |

SS420,SS431 |

|

4 |

Screw |

SS304 |

|

5 |

Retainer |

SS201 |

|

6 |

Weather seal |

NBR |

|

7 |

Bearing |

RPTFE with Graphite on I.D. |

|

8 |

Lower Stem |

SS420, SS431 |

|

9 |

Bottom cover |

Same as body |

|

10 |

Bolt |

SS304 |

|

11 |

Screw |

SS304 |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

Quality Control Process

Standards&Features:

Advantages of the flanged butterfly valve:

1.Electrostatic powder thermal spraying process valve body

Using electrostatic powder thermal spraying process, spraying thickness 250μm. Body heated at 200°C for 3 hours, powder cured at 180°C for 2 hours. After natural cooling, surface adhesion is 2 times higher than ordinary powder, more environmental protection.

2.PE heat shrinkable plastic packaging technology

Individually wrapped with heat shrinkable film and built-in desiccant. Isolation of air dust, easy storage and avoid moisture corrosion.

3.Good sealing performance

The seat adopts high specification ethylene propylene diene rubber, so that the rebounding and pulling force of the butterfly valve is stable and reliable, and there is no leakage of more than 10,000 times.

4.QT450-10 material

The body and disc are made of QT450-10 material, the ball rate is above 3, the mechanical properties are completely up to standard. The tensile strength is 450MPa, the extension rate is more than 10%, and it is not easy to break or freeze.

5.Solid valve body

The valve body is solid, the same caliber weight is heavier than other manufacturers.

Case:

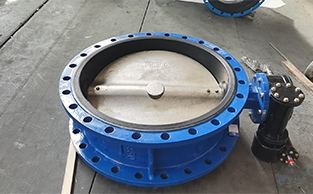

Pakistan Sewage Treatment Plant Project

Main products: Flanged Butterfly Valves and Gate Valves

This case is an old customer from Pakistan. Because he has purchased valve products from WEIZIDOM many times, he has very high trust and evaluation on WEIZIDOM. He needs a lot of butterfly valves and gate valve products in the sewage treatment plant project which he is responsible for. They sent the requirements to the businessman of WEIZIDOM's international trade department without hesitation. Of course, WEIZIDOM still returns this old customer in Pakistan with high-quality products and preferential prices;

After that, the customer also sent us the installation pictures of the WEIZIDOM product in the working condition project, and feedback that the quality is still very good, and will maintain a long-term cooperative relationship with WEIZIDOM;

Project pictures:

Application:

DI flange butterfly valves are commonly used in various industrial and commercial applications where reliable and efficient flow control is required. Some of the common applications of DI flange butterfly valves include:

1. Water Treatment Systems:

DI flange butterfly valves are widely used in water treatment systems for controlling the flow of water and other fluids. They are commonly used in applications such as water distribution systems, water treatment plants, and pumping stations.

2. HVAC Systems:

DI flange butterfly valves are used in heating, ventilation, and air conditioning (HVAC) systems for controlling the flow of air and water. They are commonly used in applications such as cooling towers, air handling units, and heat exchangers.

3. Chemical Processing:

DI flange butterfly valves are used in chemical processing plants for controlling the flow of chemicals and other fluids. They are commonly used in applications such as mixing tanks, reactors, and distillation columns.

4. Food and Beverage Processing:

DI flange butterfly valves are used in food and beverage processing plants for controlling the flow of liquids and gases. They are commonly used in applications such as fermentation tanks, bottling lines, and storage tanks.

5. Marine Industry:

DI flange butterfly valves are used in marine applications for controlling the flow of seawater, fuel, and other fluids. They are commonly used in applications such as ballast systems, bilge systems, and seawater cooling systems.

Please fill in your procurement needs and contact information