Full PTFE lined butterfly valve wafer type

Features:

Size: 2''- 44''/DN50-DN1200

Pressure: 5K/10K/150LB

Body Materials: CI/DI/WCB/CF3/ CF3M/CF8/ CF8M

Seat Materials: NBR/EPDM/PTFE

Disc Materials: DI/WCB/CF3/ CF3M/CF8/CF8M/ C954

Stem Materials: 45#/410/ 2Cr13/Cr13/304/316stainless steel

Operate Manual, Worm gear, Pneumatic, Electric-Motorized

We're here to help:

Easy ways to get the answers you need.

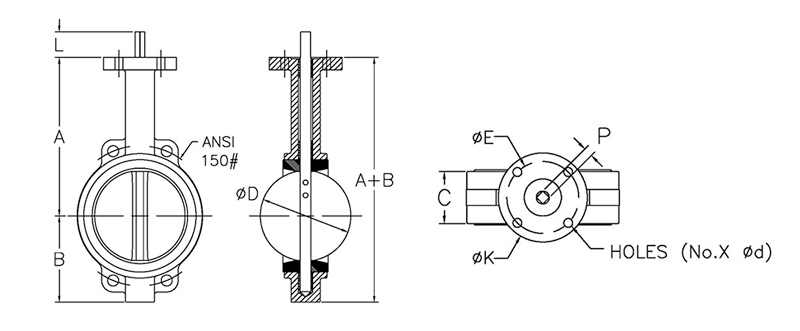

Parameter:

A lined fluorine butterfly valve is a type of valve that is designed for use in highly corrosive environments. It features a body and disc lined with a fluorine-based material, such as PTFE (polytetrafluoroethylene) or FEP (fluorinated ethylene propylene), providing excellent resistance to chemical attack. The valve operates by rotating the disc to control the flow of fluid through the valve. The lined fluorine butterfly valve is commonly used in chemical processing, oil and gas, and other industries with aggressive chemicals.

| DN | Size | L | A | B | D | C | H | ISO5211 | n-ød PN10 | n-ødPN16 |

| 100 | 4" | 127 | 155 | 114 | 220 | 180 | 225 | F07 | 8-ø19 | 8-ø19 |

| 125 | 5" | 140 | 170 | 125 | 250 | 210 | 240 | F07 | 8-ø19 | 8-ø19 |

| 150 | 6" | 140 | 190 | 143 | 285 | 240 | 260 | F07 | 8-ø23 | 8-ø23 |

| 200 | 8" | 152 | 205 | 170 | 340 | 295 | 305 | F10 | 8-ø23 | 12-ø23 |

| 250 | 10" | 165 | 235 | 198 | 405 | 355 | 335 | F10 | 12-ø23 | 12-ø28 |

| 300 | 12" | 178 | 280 | 223 | 460 | 410 | 380 | F10 | 12-ø23 | 12-ø28 |

| 350 | 14" | 190 | 310 | 279 | 520 | 470 | 410 | F10 | 16-ø23 | 16-ø28 |

| 400 | 16" | 216 | 340 | 300 | 580 | 525 | 480 | F14 | 16-ø26 | 16-ø31 |

| 450 | 18" | 222 | 375 | 345 | 640 | 585 | 530 | F14 | 20-ø26 | 20-ø31 |

| 500 | 20" | 229 | 430 | 355 | 705 | 650 | 600 | F14 | 20-ø26 | 20-ø34 |

| 600 | 24" | 267 | 500 | 410 | 840 | 770 | 676 | F16 | 20-ø30 | 20-ø36 |

| 700 | 28 | 292 | 560 | 478 | 910 | 840 | 740 | F25 | 24-ø30 | 24-ø36 |

| 800 | 32 | 318 | 620 | 529 | 1020 | 950 | 800 | F25 | 24-ø33 | 24-ø39 |

| 1000 | 40 | 410 | 735 | 657 | 1225 | 1170 | 1045 | F25 | 28-ø36 | 28-ø42 |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

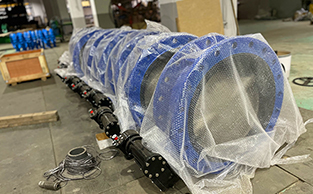

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Advantage of lined fluorine butterfly valve !

1. Excellent chemical resistance

The fluorine-based lining material provides exceptional resistance to a wide range of aggressive chemicals, making them ideal for use in highly corrosive environments.

2. Low friction

The smooth surface of the lining material reduces the friction between the valve components, minimizing wear and extending the valve’s lifespan.

3. Lightweight

The use of non-metallic materials in the valve construction makes it lightweight and easy to install and maintain.

4. Low torque operation

The design of the valve allows it to operate with minimal torque, reducing the cost and complexity of actuation systems.

5. Versatile

Lined fluorine butterfly valves can be used in a wide range of applications, including chemical processing, oil and gas, and water treatment.

6. Cost-effective

Compared to other types of valves designed for use in corrosive environments, lined fluorine butterfly valves are often more cost-effective, making them an attractive option for many industries.

Application:

A full PTFE (polytetrafluoroethylene) lined butterfly valve is a type of valve that has a PTFE lining on the wetted parts of the valve, including the disc, stem, and seat. This lining provides excellent chemical resistance and is ideal for applications where corrosive or abrasive fluids are being transported. Some common applications of full PTFE lined butterfly valves include:

1. Chemical processing plants

Full PTFE lined butterfly valves are commonly used in chemical processing plants to control the flow of various corrosive chemicals.

2. Pharmaceutical industry

These valves are used in the pharmaceutical industry to regulate the flow of various fluids and chemicals used in the manufacturing of drugs.

3. Water treatment plants

Full PTFE lined butterfly valves are used in water treatment plants to regulate the flow of water and other fluids.

4. Petrochemical industry

These valves are used in the petrochemical industry to regulate the flow of various liquids and gases.

5. Food and beverage industry

Full PTFE lined butterfly valves are commonly used in the food and beverage industry to regulate the flow of various fluids like water, juice, milk, etc.

6. Mining industry

These valves are used in the mining industry to control the flow of corrosive and abrasive fluids during the extraction and processing of minerals.

7. Power generation industry

Full PTFE lined butterfly valves are used in power generation plants to regulate the flow of steam, water, and other fluids in the turbines and other equipment.

Please fill in your procurement needs and contact information