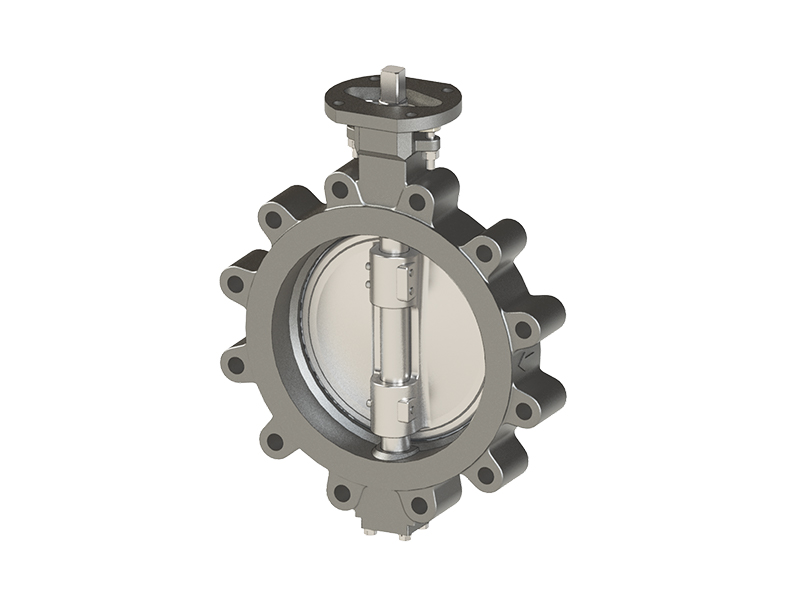

High performance butterfly valve

Features:

Size: NPS 2 to 66 / DN 50 to 1500

Testing Standard: API 598

Face to Face: API 609, ISO 5752

Body Style: Wafer, Lug, Double Flanged

Temperature Range: -62°F to 500°F (-52°C to 260°C)

Applications: High Pressure, High Temperature, Critical Service

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is high performance butterfly valve?

The high performance butterfly valve (also known as a double offset butterfly valve) features an innovative design that offers rugged reliability and extremely easy maintenance in the field. Independent and long service life capability, with zero leakage shutoff.

A high-performance butterfly valve is a type of valve that is designed for high-pressure and high-temperature applications. It typically features a metal seat and a metal disc mounted on a shaft, which can be rotated to control fluid flow through the valve. The design of a high-performance butterfly valve allows for precise control of flow rates, and it is often used in industries such as oil and gas, chemical processing, and power generation. These valves are also known for their durability and reliability, and they are often preferred over other types of valves because of their low cost, ease of operation, and low maintenance requirements.

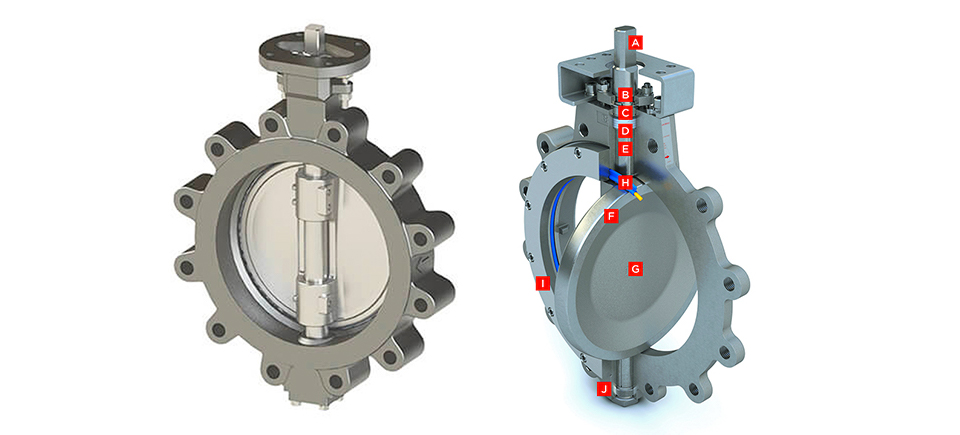

|

A. Stem |

The high-strength, one piece stem is Stainless Steel. The valve stem is standardized for interchangeability of wesdom actuators. |

|

B. Blow-out Proof Stem |

A retaining ring is installed between the machined stem groove and gland retainer step. |

|

C. Adjustable Stem Packing |

The stem packing system features easy access to adjusting hex head nuts without requiring removal of the actuator. |

|

D. Stem Seal |

The stem seal system provides constant compression for a positive seal around the stem. PTFE packing seals the stem and a carbon fiber anti–extrusion ring contains the packing. Flexible graphite rings are available for high temperature applications and are standard on fire safe valves. |

|

E. Stem Bearings |

Top and bottom bearings, consisting of a 316 Stainless Steel shell with a TFE/glass fabric liner bearing surface securely support the stem. The stem bearings provide excellent resistance to corrosion and distortion from high temperatures and mechanical loading forces. |

|

F. Taper Pins |

Taper pins are precision fit into reamed holes. |

|

G. Disc |

The disc has been engineered to maximize flow and minimize resistance providing a high Cv. Stainless Steel is standard. |

|

H. Internal Travel Stop |

Designed to prevent travel of the disc and minimizing possible seat damage, therefore extending the service life of the seat. |

|

I. Resilient Seat |

Energizer encapsulated in RTFE |

|

J. Full-faced Seat Retainer |

Retainer is firmly attached by bolts located outside of sealing area, protecting the bolts from corrosion. |

|

K. Body |

All body styles offer bi-directional sealing as standard to full ASME Class 150, 300 or 600 ratings. Extended neck allows for 2" of pipeline insulation and easy access to stem packing adjustments and actuator mounting. |

Standards&Features:

Advantages of High-performance butterfly valve:

1. Cost-effective:

High-performance butterfly valves are typically more affordable than other types of valves, making them a cost-effective option for many applications.

2. Precise flow control:

Butterfly valves are known for their ability to provide precise flow control, which is essential in many industries.

3. Low pressure drop:

Butterfly valves have a low-pressure drop, which means that they can be used in applications where pressure is a concern.

4. Quick operation:

Butterfly valves can be operated quickly, making them ideal for applications where fast response times are required.

5. Low maintenance:

Butterfly valves are relatively low maintenance, which can help reduce overall operating costs.

6. Corrosion-resistant:

High-performance butterfly valves are often made of materials that are resistant to corrosion, making them ideal for use in harsh environments.

7. Easy installation:

Butterfly valves are easy to install and can be installed quickly, which can help reduce downtime during installation and maintenance.

8. Compact design:

Butterfly valves have a compact design, which means that they take up less space than other types of valves.

Application:

High-performance butterfly valves are designed to provide better performance and reliability than standard butterfly valves. They are widely used in various industries for regulating the flow of fluids and gases in high-temperature and high-pressure applications. Some common applications of high-performance butterfly valves include:

1. Oil and gas industry:

High-performance butterfly valves are commonly used in the oil and gas industry for regulating the flow of various fluids and gases, controlling pressure, and isolating different parts of the system.

2. Chemical processing:

High-performance butterfly valves are widely used in chemical processing industries for regulating the flow of various chemicals and fluids, controlling pressure, and isolating different parts of the system.

3. Power generation:

High-performance butterfly valves are used in power generation plants for regulating the flow of steam and gas, controlling pressure, and isolating different parts of the system.

4. Water treatment:

High-performance butterfly valves are used in water treatment plants for regulating the flow of water, controlling pressure, and isolating different parts of the system.

5. HVAC systems:

High-performance butterfly valves are also used in heating, ventilation, and air conditioning (HVAC) systems for regulating the flow of air and controlling temperature and humidity.

Please fill in your procurement needs and contact information