Inflatable seat butterfly valve

Features:

Size: DN50-DN1000

Seat Material: EPDM, NBR, FRM, PTFE

Nuts Material: Stainless steel

Screw Material: SS304

Stem Material: SS420, SS431

Application medium: Dust, Bulk materials, Slurry, Chemical Powder, Cement, Quartz Sand, Fly Ash, Ceramics, etc.

Body Material: ASTM A536 65-45-12, WCB, CF8M

We're here to help:

Easy ways to get the answers you need.

Parameter:

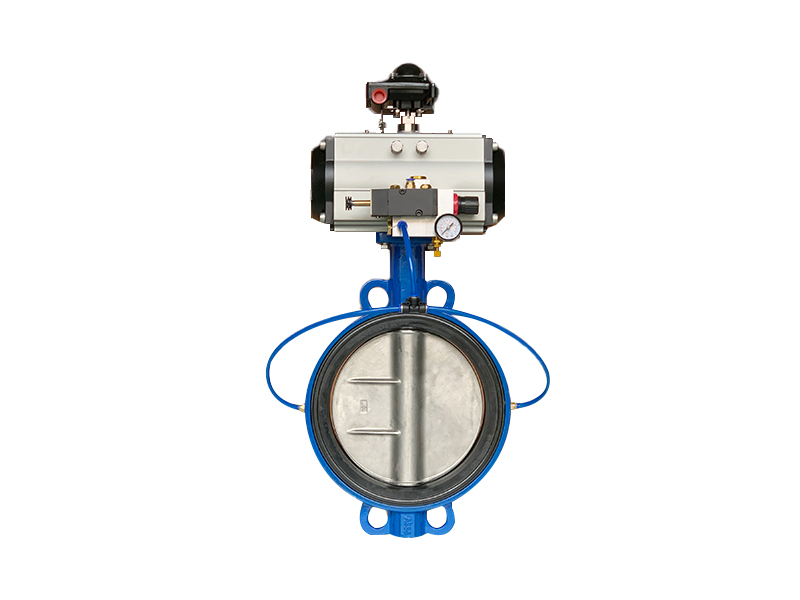

What is inflatable seat butterfly valve?

An inflatable butterfly valve, also known as an air-operated butterfly valve, is a type of valve that uses air pressure to operate. The valve consists of a butterfly disc mounted on a shaft inside a valve body. The disc is connected to an inflatable seal or bladder that is inflated or deflated with air pressure to open or close the valve. When the seal is inflated, it presses against the valve body and closes off the flow of fluid. The disc rotates when the seal is deflated to allow fluid to flow through the valve.

Inflatable butterfly valves are commonly used in applications requiring a tight, leak-proof seal, such as in water treatment, wastewater treatment, and chemical processing. They are often used when other valves may not provide a tight enough seal or may be prone to leakage. Inflatable butterfly valves are also useful in situations where manual or mechanical operation of valves is not feasible, such as in remote locations or hazardous environments. The air-operated system allows for easy and remote operation of the valve, making it a popular choice in many industries.

The inflatable seat butterfly valve is an innovative and reliable solution for controlling and regulating fluid flow in various industrial applications.

|

Part name |

Material |

|

Body |

ASTM A536 65-45-12, WCB, CF8M |

|

Disc |

ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 |

|

Seat |

EPDM,NBR,FRM.PTFE |

|

Stem |

SS420,SS431 |

|

Lower Stem |

SS420,SS431 |

|

Retalner |

Nylon for DN50-DN300, SS304 for DN350-DN2000 |

|

Bearing |

RPTFE with Graphite on I.D. |

|

Weather seal |

NBR |

|

Nuts |

Stainless steel |

|

Plug |

Steel galvanized for DN50-DN300, Cover plate for |

|

Screw |

SS304 |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Advantages of inflatable butterfly valve!

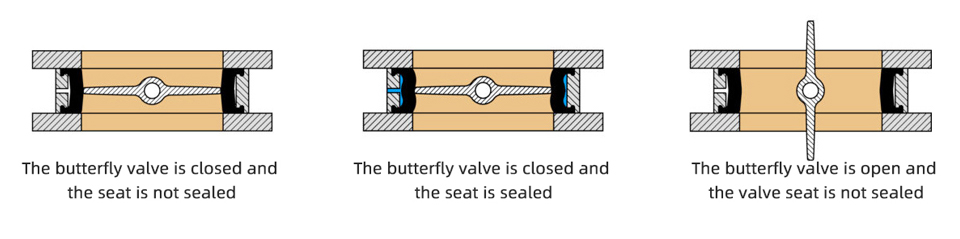

1. Inflatable Seat Design

The inflatable seat design provides excellent sealing performance and reduces wear and tear on the valve components, ensuring long service life and low maintenance costs.

2. Wide Range of Sizes

Available in sizes ranging from DN50 to DN1000, the inflatable seat butterfly valve can accommodate a variety of pipeline diameters and flow rates.

3. Various Material Options

The valve is made from a selection of high-quality materials, including ASTM A536 65-45-12, WCB, CF8M for the body, and material options like Nylon-coated ASTM A536 65-45-12, CF8, CF8M, 2507, and 1.4462 for the disc. This ensures compatibility with different media and operating

conditions.

4. Multiple Seat Materials

The seat materials can be chosen from EPDM, NBR, FRM, or PTFE, providing flexibility and compatibility with various fluids and operating temperatures.

5. Stainless Steel Components

The valve’s stem, lower stem, retainer, nuts, and screws are made from corrosion-resistant stainless steel for durability and long-lasting performance.

6. Reliable, built to last

Before delivery, we make 100% test for each product to ensure its quality.

Features of inflatable seat butterfly valve:

The unique design of the expansion butterfly valve uses gas pressure to extend the valve seat toward the valve disc to provide a smooth distribution of pressure to the seal at all times. Since only momentary contact occurs between the valve disc and the valve seat during the opening and closing of the valve, the valve disc is only slightly bumped. On the contrary, for the general butterfly valve, the collision caused by the valve disc rubbing the valve seat will reduce the performance and life of the valve.

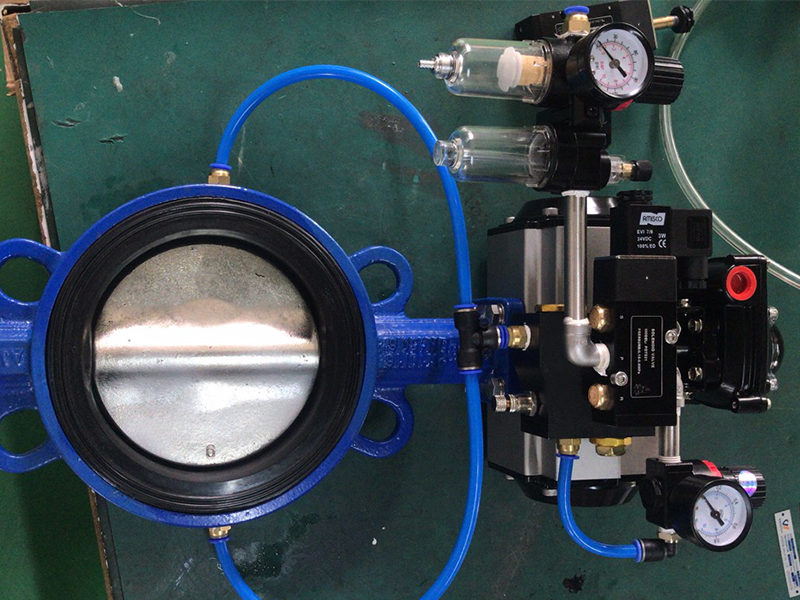

Case:

Pakistan Sewage Treatment Plant Project

Main products: Flanged Butterfly Valves and Gate Valves

This case is an old customer from Pakistan. Because he has purchased valve products from WEIZIDOM many times, he has very high trust and evaluation on WEIZIDOM. He needs a lot of butterfly valves and gate valve products in the sewage treatment plant project which he is responsible for. They sent the requirements to the businessman of WEIZIDOM's international trade department without hesitation. Of course, WEIZIDOM still returns this old customer in Pakistan with high-quality products and preferential prices;

After that, the customer also sent us the installation pictures of the WEIZIDOM product in the working condition project, and feedback that the quality is still very good, and will maintain a long-term cooperative relationship with WEIZIDOM;

Project pictures:

Application:

An inflatable seat butterfly valve is typically used in applications where the flow of fluid needs to be controlled. Some common applications include:

1. Water treatment plants

Inflatable seat butterfly valves are used in water treatment plants to regulate the flow of water and other fluids.

2. Chemical processing plants

These valves are used in chemical processing plants to regulate the flow of various chemicals and fluids.

3. Power plants

Inflatable seat butterfly valves are used in power plants to regulate the flow of water and steam in the turbines.

4. Oil and gas industry

These valves are used in the oil and gas industry to control the flow of crude oil, natural gas, and other fluids.

5. Pharmaceutical industry

Inflatable seat butterfly valves are used in the pharmaceutical industry to regulate the flow of various fluids and chemicals used in the manufacturing of drugs.

6. Food and beverage industry

These valves are used in the food and beverage industry to regulate the flow of various fluids like water, juice, milk, etc.

Please fill in your procurement needs and contact information