One stem no-pin wafer butterfly valve

Features:

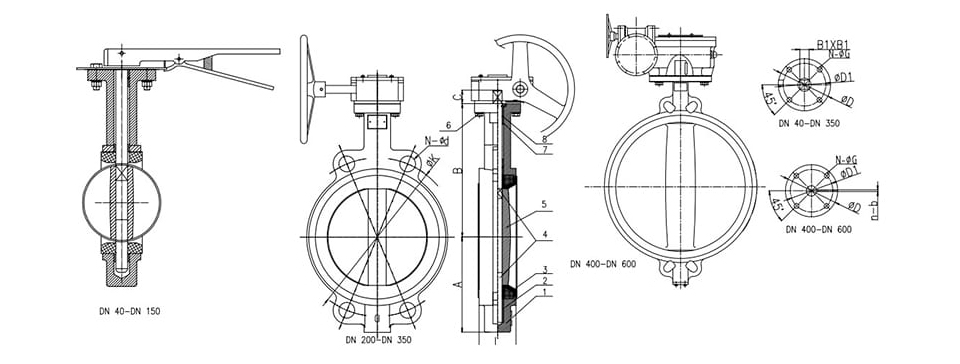

Size Range 1½"~24"(DN40~DN600)

Pressure PN10, PN16, Class125

Body Materials Cast Iron, Ductile Iron, WCB , Stainless Steel, Bronze

Seat Materials NBR, EPDM, VITON, PTFE

Disc Materials Ductile Iron, WCB, CF8,CF8M, Al-bronze C958

Stem Materials SS416, SS304, SS316

Operate Manual, Worm gear, Pneumatic, Electric-Motorized

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is a one stem no-pin wafer butterfly valve?

A one stem no-pin wafer butterfly valve is a type of valve that is used to regulate the flow of fluids or gases in a pipeline. It is called "one stem" because it has a single stem that connects the valve disc to the actuator, which controls the valve's opening and closing. It is called "no-pin" because it doesn't have a separate pin that connects the valve disc to the stem. Instead, the stem is directly attached to the valve disc, which makes it more compact and easier to install in a pipeline.

| SIZE | A | B | C | L | DIN PN10 | DIN PN16 | ANSI 150B | JIS 10K | ISO5211 | Top Flange | B1XB1 | nb | |||||||

| mm | in | ΦK | N-Φd | ΦK | N-Φd | ΦK | N-Φd | ΦK | N-Φd | ΦD | ΦD1 | N-ΦG | |||||||

| 40 | 1.5" | 67 | 141 | 32 | 33 | 110 | 4-Φ18 | 110 | 4-Φ18 | 98.5 | 4-Φ16 | 105 | 4-Φ19 | 65 | 50 | 4-Φ8 | F05 | 9X9 | - |

| 50 | 2" | 67 | 141 | 32 | 43 | 125 | 4-Φ18 | 125 | 4-Φ18 | 120.6 | 4-Φ19 | 120 | 4-Φ19 | 65 | 50 | 4-Φ8 | F05 | 9X9 | |

| 65 | 2½" | 75 | 151 | 32 | 46 | 145 | 4-Φ18 | 145 | 4-Φ18 | 139.7 | 4-Φ19 | 140 | 4-Φ19 | 65 | 50 | 4-Φ8 | F05 | 9X9 | |

| 80 | 3" | 95 | 160 | 32 | 46 | 160 | 8-Φ18 | 160 | 8-Φ18 | 152.4 | 4-Φ19 | 150 | 8-Φ19 | 65 | 50 | 4-Φ8 | F05 | 9X9 | |

| 100 | 4" | 111 | 180 | 32 | 52 | 180 | 8-Φ18 | 180 | 8-Φ18 | 190.5 | 8-Φ19 | 175 | 8-Φ19 | 90 | 70 | 4-Φ10 | F07 | 11X11 | |

| 125 | 5" | 129 | 193 | 32 | 56 | 210 | 8-Φ18 | 210 | 8-Φ18 | 215.9 | 8-Φ22.4 | 210 | 8-Φ23 | 90 | 70 | 4-Φ10 | F07 | 14X14 | |

| 150 | 6" | 142 | 207 | 32 | 56 | 240 | 8-Φ22 | 240 | 8-Φ22 | 241.3 | 8-Φ22.4 | 240 | 8-Φ23 | 90 | 70 | 4-Φ10 | F07 | 14X14 | |

| 200 | 8" | 170 | 240 | 45 | 60 | 295 | 8-Φ22 | 295 | 12-Φ22 | 298.4 | 8-Φ22.4 | 290 | 12-Φ23 | 125 | 102 | 4-Φ12 | F10 | 17X17 | |

| 250 | 10" | 206 | 270 | 45 | 68 | 350 | 12-Φ22 | 355 | 12-Φ22 | 361.9 | 12-Φ25.4 | 355 | 12-Φ25 | 125 | 102 | 4-Φ12 | F10 | 22X22 | |

| 300 | 12" | 238 | 316 | 45 | 78 | 400 | 12-Φ22 | 410 | 12-Φ26 | 431.8 | 12-Φ25.4 | 400 | 16-Φ25 | 125 | 102 | 4-Φ12 | F10 | 22X22 | |

| 350 | 14" | 267 | 368 | 45 | 78 | 460 | 16-Φ22 | 470 | 16-Φ26 | 476.2 | 12-Φ28.4 | 445 | 16-Φ25 | 125 | 102 | 4-Φ12 | F10 | 22X22 | |

| 400 | 16" | 298 | 400 | 51 | 86 | 515 | 12-Φ26 | 525 | 16-Φ30 | 539.7 | 16-Φ28.4 | 510 | 16-Φ27 | 175 | 140 | 4-Φ18 | F14 | - | 1--10 |

| 450 | 18" | 318 | 422 | 51 | 105 | 565 | 20-Φ26 | 585 | 20-Φ30 | 577.8 | 16-Φ31.8 | 565 | 20-Φ27 | 175 | 140 | 4-Φ18 | F14 | 1--10 | |

| 500 | 20" | 349 | 479 | 57 | 130 | 620 | 20-Φ26 | 650 | 20-Φ33 | 635 | 20-Φ31.8 | 620 | 20-Φ27 | 175 | 140 | 4-Φ18 | F14 | 1--12 | |

| 600 | 24" | 410 | 562 | 70 | 152 | 725 | 20-Φ30 | 770 | 20-Φ36 | 749.3 | 20-Φ35.1 | 730 | 24-Φ33 | 210 | 165 | 4-Φ22 | F16 | 1--16 | |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Advantages of one stem no-pin wafer butterfly valve:

1.Wesdom patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The thickness of valve body wall is up to standard

The valve body wall thickness meets the requirement of GB 26640, the thickness is up to the standard, and the pressure strength is guaranteed.

3.Valve body valve plate is made of QT450-10 material

Valve body valve plate is made of qt450-10 material with spheroidization rate above grade 3, tensile strength of 450Mpa and elongation of >10%.

4.Good sealing and long service life of valve seat

The valve seat is made of imported rubber material, with more than 50% rubber content; Elongation at break greater than 350%, valve sealing reliable, long life.

5.Soft back with wide side seat

Soft backrest wide side valve seat, is advantageous to the valve installation, in the pipeline and flange boss contact surface is wide, sealing performance is reliable. Life is longer than a hard back. And easy to remove and replace.

6.No pin structure to avoid corrosion

Butterfly plate and valve shaft adopt through shaft without pin structure to avoid leakage caused by hole mounting pin and accelerated corrosion caused by coating damage.

7.Valve body is sprayed with Aksu epoxy powder

The valve body is sprayed with world-renowned Aksu epoxy resin powder, which has stronger adhesion and better environmental tolerance after melting and curing.

Case:

Tanzania Water Project

Main products: Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client feedback:

The customer sent us the installation pictures of the WEIZIDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WEIZIDOM;

Project pictures:

Application:

One stem no-pin wafer butterfly valves are commonly used in the following applications:

1. HVAC systems:

These valves are used in heating, ventilation, and air conditioning (HVAC) systems to regulate the flow of air and water.

2. Water treatment plants:

These valves are used in water treatment plants to control the flow of water through different stages of the treatment process.

3. Chemical processing:

One stem no-pin wafer butterfly valves are used in chemical processing plants to regulate the flow of chemicals through pipelines.

4. Food and beverage processing:

These valves are used in food and beverage processing plants to control the flow of liquid and semi-solid materials.

5. Pharmaceutical industry:

These valves are used in the pharmaceutical industry to control the flow of different fluids and chemicals during the manufacturing process.

6. Oil and gas industry:

One stem no-pin wafer butterfly valves are used in the oil and gas industry to control the flow of oil and gas through pipelines.

7. Power generation:

These valves are used in power generation plants to regulate the flow of water and steam through different stages of the power generation process.

Please fill in your procurement needs and contact information