Stainless Steel wafer Butterfly Valve

Features:

DN: 2~8"(DN50~DN200)

Nominal pressure: PN10, PN16, Class125

Body Materials: SS304, SS316

Seat Materials: NBR, EPDM, VITON, PTFE

Disc Materials: CF8,CF8M

Stem Materials: SS416, SS304, SS316

End Connection: Lug

We're here to help:

Easy ways to get the answers you need.

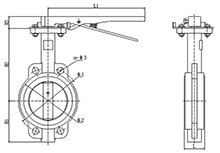

Parameter:

| Size | H1 | H2 | H3 | L | L1 | φ1 | φ2 | N | φ3 | |||||||

| mm | inch | ANSIB16.1 | DINPN10 | DINPN16 | JIS5K | JIS10K | ANSI | DIN | JIS | |||||||

| 40 | 1.5" | 60 | 130 | 32 | 36 | 267 | 98.5 | 110 | 110 | — | — | 82 | 4 | 17.46 | 18 | — |

| 50 | 2″ | 76 | 162 | 32 | 45 | 267 | 120.65 | 125 | 125 | 105 | 120 | 88 | 4 | 17.46 | 18 | 15/19 |

| 65 | 21/2″ | 89 | 175 | 32 | 48 | 267 | 139.7 | 145 | 145 | 130 | 140 | 108 | 4 | 17.46 | 18 | 15/19 |

| 80 | 3″ | 95 | 181 | 32 | 49 | 267 | 152.4 | 160 | 160 | 145 | 150 | 118 | 4 | 17.46 | 18 | 19 |

| 100 | 4″ | 114 | 200 | 32 | 55 | 267 | 190.5 | 180 | 180 | 165 | 175 | 156 | 4 | 17.46 | 18 | 19 |

| 125 | 5″ | 127 | 213 | 32 | 58 | 267 | 215.9 | 210 | 210 | 200 | 210 | 181 | 4 | 20.64 | 18 | 19/23 |

| 150 | 6″ | 140 | 225 | 32 | 59 | 267 | 241.3 | 240 | 240 | 230 | 240 | 210 | 4 | 20.64 | 22 | 19/23 |

| 200 | 8″ | 177 | 260 | 45 | 64 | 356 | 298.45 | 295 | 295 | 280 | 290 | 260 | 4 | 20.64 | 22 | 23 |

| 250 | 10″ | 203 | 292 | 45 | 70 | 356 | 361.95 | 350 | 355 | 345 | 355 | 321 | 4 | 23.81 | 22/26 | 23/25 |

| 300 | 12″ | 242 | 337 | 45 | 80 | 356 | 431.8 | 400 | 410 | 390 | 400 | 384 | 4 | 23.81 | 22/26 | 23/25 |

Standards&Features:

| Item | Name | Material |

| 1 | Body | 304/316 |

| 2 | Bushing | polymer |

| 3 | Seat | PTFE |

| 4 | Disc | CF8/CF8M/Al-bronze |

| 5 | Stem | SS416/SS304/SS316 |

| 6 | Pin ; | SS316/SS416 |

| 7 | Disc type | With stem,One stem no-pin,Double stem no-pin |

| 8 | O-ring | NBR |

Case:

1.Single Eccentric Disc-Shaft

2.Anti-Blow Out Stem

3.Bi-Directional

4.Fire safe Design

5.Low Friction Body Seat

6.Zero Leakage

Why Choose Us:

1.We promise no leakage and breakage for valves. Every butterfly valve will test for 2 times test pressure before leave factory. We will replace the valve if there is quality problem within 24 months guarantee period.

2.We obtained ISO9001 quality system certification.We inspect the parts of valve carefully, 48 produce steps, try to supply you ideal valve.

3.We can supply different kinds of materials according to customers' requests,such as DI,cast steel,SS304,SS316 body and disc. EPDM,NBR,PTFE,Viton etc. Enough stock ensure fast delivery.

4.We have more than 150 types body moulds, which include ISO,DIN,ANSI,BS standard.

5.We own full-automatic machine paint line, match high-temperature baking house,which makes smooth paint and good appearance of valve.

Standard Test :

Body Test: 1.5 times the working pressure with water. This test is performed after valve assembly and with disc in half position open, it is called as a body hydro test.

Seat Test: 1.1 times the working pressure with water.

Function / Operation Test: At the time of final inspection, each valve and its actuator (Flow-Control Lever / Gear / Pneumatic Actuator), under goes a complete operating test (Open/Close). This test carried out without pressure and at ambient temperature.

Special Test: On request, any other test can be carried out according to special instruction by client.

Application:

1.Water Treatment Plant ;

2.Drilling Rigs;

3.Paper Industry;

4.Gas Plant;

5.Sugar Industry;

6.Cooling Water Circulation;

7.Breweries;

8.Heating & Air Conditioning;

9.Chemical Industry;

10.Pneumatic Conveyors;

11.Waste Effluent Treatment Plant ;

12.Compressed Air.

Please fill in your procurement needs and contact information