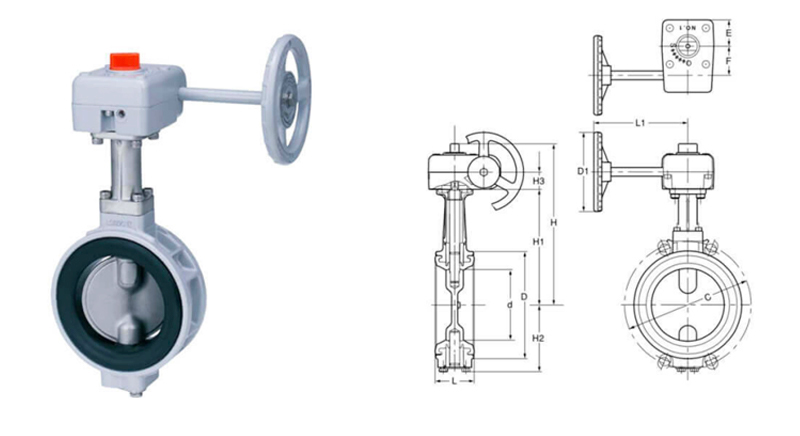

Worm Gear Aluminum Butterfly Valve

Features:

Size: DN50-DN300

Pressure Rating: PN10 & PN 16,150LB

Material: NBR/EPDM,304/316

Design Standard: BS 5155,EN593, API 609

Inspection Standard: EN12266, API 598,GB/T 13927-92

Application medium: Water

Application Temperature: NBR 0-70G,EPDM 0-120'℃

We're here to help:

Easy ways to get the answers you need.

Parameter:

The aluminum alloy butterfly valve is made of high-performance material, which can effectively prevent the temperature difference of the valve body, isolate the transfer of medium in the pipeline and not condense on the surface of the actuator and flange. The high performance material has many outstanding advantages: such as low water absorption, corrosion resistance, heat insulation, cold resistance, etc., which is four times more than ordinary materials. Anti-condensation butterfly valve is suitable for HVAC, central air conditioning, and water supply equipment, widely used in water, gas, petroleum, chemical, smelting, energy, shipbuilding, electric power, oil, water treatment, construction, and other industries.

Anti-condensation butterfly valves are generally made of aluminum alloy body and light weight driving device. The aluminum alloy valve body has strong corrosion resistance and is light in weight, making it easy to install; the butterfly plate is surrounded by a spherical structure, which is conducive to reducing the friction torque with the valve seat; the butterfly plate and valve shaft are made of stainless steel, which increases the ability to prevent rust and corrosion and at the same time plays a role in reducing heat transfer and preventing the temperature of the drive unit from being too low; the housing of the drive unit is made of aluminum alloy, which is light in weight and dissipates heat quickly, which is conducive to the distribution of moisture; the vulcanized rubber valve seat and The use of vulcanized rubber seats and long steel necks further reduce heat transfer.

| Size | d | H | H1 | H2 | H3 | L | C Gear D | |||||||||

| mm | inch | 10K | Class150 | PN16 | D1 L1 E F type | |||||||||||

| 40 | 1 1/2 | 40 | 175 | 128 | 40 | 19 | 33 | 80 | 105 | 98.5 | - | 80 | 122 | 29 | 28 | No.0 |

| 50 | 2 | 50 | 179 | 132 | 66 | 19 | 43 | 93 | 120 | 120.5 | 125 | 80 | 122 | 29 | 28 | No.0 |

| 65 | 2 1/2 | 65 | 188 | 141 | 74 | 19 | 46 | 118 | 140 | 139.5 | 145 | 80 | 122 | 29 | 28 | No.0 |

| 80 | 3 | 80 | 196*2 | 149 | 83 | 19 | 46 | 129 | 150 | 152.5 | 160 | 80 | 122 | 29 | 28 | No.0 |

| 100 | 4 | 100 | 223 | 1 60 | 94 | 24 | 52 | 149 | 175 | 190.5 | 180 | 110 | 135 | 36 | 40 | No.1 |

| 125 | 5 | 125 | 258 | 195 | 122 | 24 | 56 | 184 | 210 | 216 | 210 | 110 | 150 | 36 | 40 | No.1 |

| 150 | 6 | 150 | 270 | 207 | 135 | 24 | 56 | 214 | 240 | 241.5 | 240 | 110 | 150 | 36 | 40 | No.1 |

| 200 | 8 | 196 | 311 | 234 | 161*1 | 32 | 60 | 258 | 290 | 298.5 | 295 | 170 | 180 | 51 | 63 | No.2 |

| 250 | 10 | 245 | 405 | 328 | 238 | 32 | 68 | 316 | 355 | 362 | - | 170 | 180 | 51 | 63 | No.2 |

| 300 | 12 | 295 | 430 | 353 | 263 | 32 | 78 | 367 | 400 | - | - | 170 | 180 | 51 | 63 | No.2 |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Advantages of aluminum butterfly valve:

1. High sealing performance

Wide disc seating contact for high sealing performance;

Stem seal bearings are assembled on the top and bottom stems for stable sealing

Reinforced ribbing minimizes valve operating problems such as distortion, skidding, and exfoliation of rubber liners caused by line pressure load and friction with metal discs;

2. Aluminum die-cast valve body to prevent corrosion

Light aluminum alloy valve body, small torque, easy to use and install;

3. Longer valve seat service life

Some multi-level progressive contact valve seat design allows the valve plate to gradually contact the valve seat during the closing process, which reduces unnecessary torque while ensuring good sealing performance, thereby prolonging the service life of the valve seat;

4. Good anti-corrosion and sealing performance

Some valve stem sealing rings prevent fluid leakage;Valve seats of different materials adapt to different working conditions and have good anti-corrosion and sealing performance;

5. Multi-stage progressive contact valve seat design

The unique multi-level progressive contact seat design of the anti-condensation butterfly valve makes the valve plate gradually contact the seat during the closing process.

6. Valve body is made of light aluminum alloy body

The valve body is made of light aluminum alloy body, with low torque, preventing rust, and preventing long-term circulation of chilled water in the air conditioner.

7. Stronger anti-condensation function

The low temperature of the fluid in the pipeline follows the conduction of the butterfly valve metal material and exchanges with the ambient air temperature to produce condensation.

8. The valve plate is processed as a complete spherical shape

Each part of the sealing surface is a part of the spherical surface, even the axial sealing surface at the upper and lower parts of the valve plate.

Application:

Aluminum butterfly valves are commonly used in various industrial applications where high performance and durability are required. Some of the common applications of aluminum butterfly valves include:

1. Chemical processing plants

Aluminum butterfly valves are used in chemical processing plants to control the flow of various chemicals and fluids.

2. Water treatment plants

These valves are used in water treatment plants to regulate the flow of water and other fluids.

3. Petrochemical industry

Aluminum butterfly valves are commonly used in petrochemical industry to regulate the flow of various liquids and gases.

4. Food and beverage industry

These valves are used in food and beverage industry to regulate the flow of various fluids like water, juice, milk, etc.

5. HVAC systems

Aluminum butterfly valves are used in heating, ventilation, and air conditioning (HVAC) systems to regulate the flow of air and other fluids.

6. Pharmaceutical industry

Aluminum butterfly valves are used in the pharmaceutical industry to regulate the flow of various fluids and chemicals used in the manufacturing of drugs.

7. Marine industry

These valves are used in the marine industry to regulate the flow of seawater, freshwater, and other fluids in ships and boats.

Please fill in your procurement needs and contact information