Cage Guided Sleeve Globe Control Valve

Features:

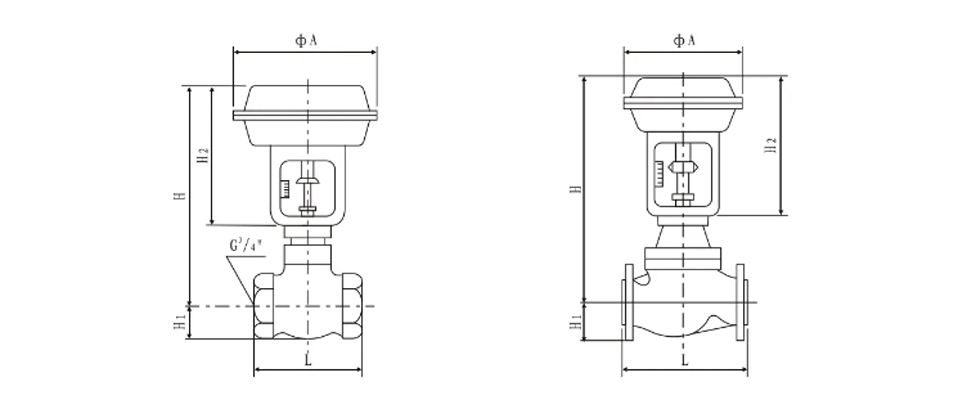

Size: 2"~24” DN40~DN600

Pressure range: ASME 150~900# PN1.6~PN16.0MPa

Leakage performance standards: ASME B16.104 GB/T4213-2008/GB/T17213.IEC60534

Flange type: JB/T79-2015 GB/T9113-2010 HG/T20592-2009/ASMEB16.5

Butt welding: GB/T9124-2010/ASME B16.25 GB/T12224-2015 Butt welding end

Temperature range: -100℃-560°℃

Body type: straight-through, angled,Z-shaped

We're here to help:

Easy ways to get the answers you need.

Parameter:

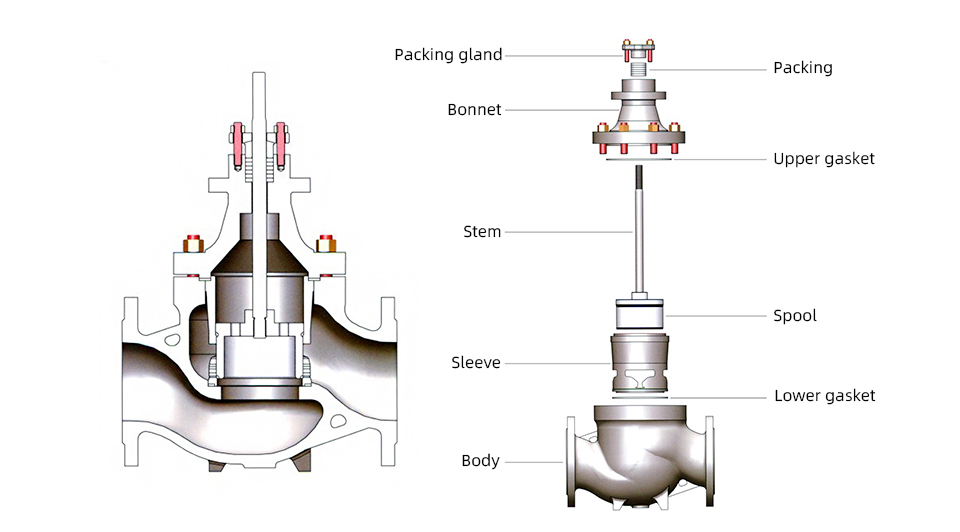

It adopts a sleeve guide structure and pressure-balanced valve core designed for heavy load conditions. It adopts a double valve seat seal and is used on occasions where leakage requirements are not high. The valve body has a compact structure and the fluid channel is S streamlined. There is a guide vane to improve the balanced flow of fluid around the sleeve. The advantages are that the pressure drop loss is small, the flow rate is large, the adjustable range is wide, and the high flow characteristic accuracy. The valve core uses the pressure balance structure and can control high pressure and other working conditions through the light and small thrust of the actuator. It is widely used in fluid control of pipelines requiring good dynamic stability, high temperature, and high pressure. Cage guide, large guide area, good stability, and compact structure.

| DN (mm) | L(mm) | H( mm) | Hl(mm) | Weight(Kg) | øA (mm) | |||||||

| ANSI25FF ANSI150RF JIS10KFF.RF PN0.6/1.6 | ANSI300 JIS20 30KRF PN4.0 | ANSI600 JIS40K.RF PN6.4 | Regular Iype | High Temper -ature Type | PN6 | PN16 | PN40 | PN64 | PN6 PN16 | PN40 PN64 | ||

| G3/4" | 120 | 120 | 120 | 253 | 31 | 32 | 11 | 12 | 236 | |||

| 20 | 181 | 194 | 206 | 398.5 | 548.5 | 45 | 52.5 | 65 | 19 | 23 | 285 | |

| 25 | 184 | 197 | 210 | 410.5 | 560.5 | 50 | 57.5 | 70 | 20 | 24 | ||

| 40 | 222 | 235 | 251 | 455 | 620 | 65 | 75 | 85 | 26 | 35 | ||

| 50 | 280 | 267 | 286 | 457.5 | 627.5 | 70 | 82.5 | 90 | 30 | 40 | ||

| 65 | 286 | 292 | 311 | 610 | 790 | 80 | 92.5 | 102.5 | 47 | 66 | 360 | |

| 80 | 298 | 317 | 337 | 622 | 807 | 95 | 100 | 107.5 | 55 | 78 | ||

| 100 | 345 | 368 | 394 | 640 | 850 | 105 | 110 | 17.5 | 125 | 65 | 99 | |

| 150 | 465 | 473 | 508 | 870 | 1130 | 132.5 | 142.5 | 150 | 172.5 | 102 | 145 | 470 |

| 200 | 555 | 610 | 650 | 890 | 1150 | 160 | 170 | 187.5 | 207.5 | 140 | 184 | |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Valve trim features:

Double seat structure,sleeve guide balanced trim, split or integral standard cage

Body type:

Straight-through, angled,Z-shaped

Upper bonnet type:

Normal temperature type, high temperature heat dissipation type, extension type

Temperature range:

-100℃-560°℃

Stem Seal Type:

Standard Standard Packing Seal

High temperature type packing seal, bellows seal(optional)

Standard leak class:

CLASS IV(standard, metal seat)

Flow characteristics:

Equal percentage, straight line

Connection with pipelines:

Flange, butt welded

Adjustable ratio:

50:1

Case:

WEIZIDOM Group specializes in pipeline fluid systems: R&D, production and sales of valves, pipe fittings, water meters, flow meters, etc. The products cover cast iron, cast steel, stainless steel, copper, plastics and other materials, which are widely used in hydropower stations, heat, buildings, Water supply and drainage, petroleum, chemical industry, electric power, medical and other fields.

Why more and more customers are choosing wesdom valves:

1. There is a professional technical team, and quality is guaranteed

2. Independent factory, more favorable price

3. Extensively trained employees are well-versed in all aspects of flow control technology

Application:

Food & Beverage

Water & Wastewater

Ultra Pure Water

Desalination

Chemical

Textile

Pharmaceutical

Pulp & Paper

Mining

Boiler and Power Industries

Please fill in your procurement needs and contact information