3 Piece ball valve

Features:

Size: 1/4” – 4" (DN8-100)

Body Design: 3 PCs Body Design

Material: Stainless Steel SS316

Working Pressure: 1000 PSI

Connection Type: BSPP / NPT/ Socket Welding End / Butt Welding End

Operations: Standard Bore, Quarter Turn

Temperature Range: -29°C to 150°C

We're here to help:

Easy ways to get the answers you need.

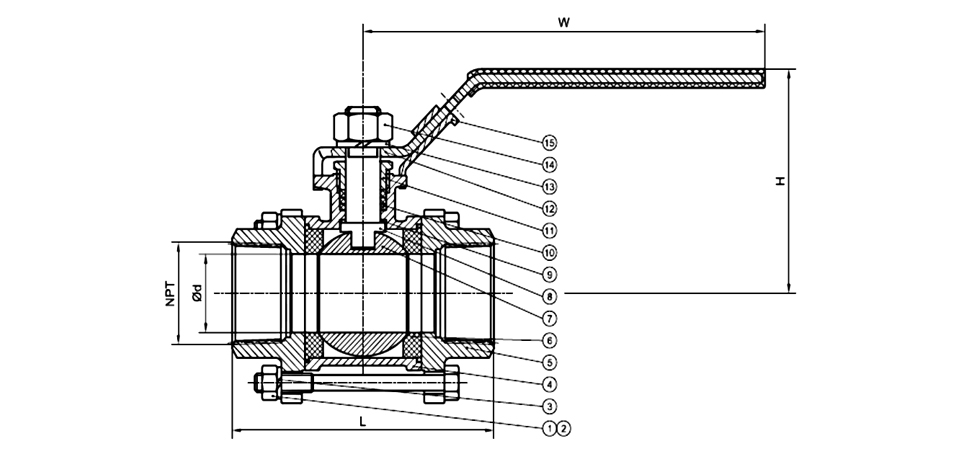

Parameter:

3 PCs threaded end ball valve consists of 3 pieces, the valve body and 2 pieces threaded end connection. This 3 pieces can be assembly together by using bolts to go through the bolt hole outside of threaded connection and tighten with nuts. The 2 pieces threaded end connection have to connect with threaded type pipe end before the valve body assembly on it. The valve body can be removed for repair purpose by removing the nuts and bolts, without remove the end connections. It is available in stainless steel SS316 material and come with PTFE sealing material.

|

NPS |

Connection |

IMPA Code |

Part No |

d |

L |

H |

E |

PCD |

Weight (kg) |

|

1/4" |

BSPP |

- |

VL-S-B1-G-1000-04 |

10 |

66 |

45 |

100 |

- |

0.30 |

|

3/8" |

BSPP |

- |

VL-S-B1-G-1000-06 |

12 |

66 |

45 |

100 |

- |

0.30 |

|

1/2" |

BSPP |

- |

VL-S-B1-G-1000-08 |

15 |

73 |

53 |

104 |

33 |

0.51 |

|

3/4" |

BSPP |

- |

VL-S-B1-G-1000-12 |

20 |

79.5 |

58 |

118 |

39.5 |

0.73 |

|

1" |

BSPP |

- |

VL-S-B1-G-1000-16 |

25 |

86.5 |

68 |

145 |

43.5 |

0.91 |

|

1 1/4" |

BSPP |

- |

VL-S-B1-G-1000-20 |

32 |

108 |

81 |

162 |

55.5 |

1.56 |

|

1 1/2" |

BSPP |

- |

VL-S-B1-G-1000-24 |

38 |

118 |

85 |

180 |

60 |

1.86 |

|

2" |

BSPP |

- |

VL-S-B1-G-1000-32 |

50 |

144 |

92 |

180 |

75 |

2.98 |

|

2 1/2" |

BSPP |

- |

VL-S-B1-G-1000-40 |

65 |

180 |

115 |

242 |

94 |

6.65 |

|

3" |

BSPP |

- |

VL-S-B1-G-1000-48 |

80 |

209 |

130 |

242 |

100 |

10.07 |

|

4" |

BSPP |

- |

VL-S-B1-G-1000-64 |

- |

- |

- |

- |

123 |

17.79 |

|

1/4" |

NPT |

- |

VL-S-B1-N-1000-04 |

10 |

66 |

45 |

100 |

- |

0.30 |

|

3/8" |

NPT |

- |

VL-S-B1-N-1000-06 |

12 |

66 |

45 |

100 |

- |

0.30 |

|

1/2" |

NPT |

- |

VL-S-B1-N-1000-08 |

15 |

73 |

53 |

104 |

33 |

0.51 |

|

3/4" |

NPT |

- |

VL-S-B1-N-1000-12 |

20 |

79.5 |

58 |

118 |

39.5 |

0.73 |

|

1" |

NPT |

- |

VL-S-B1-N-1000-16 |

25 |

86.5 |

68 |

145 |

43.5 |

0.91 |

|

1 1/4" |

NPT |

- |

VL-S-B1-N-1000-20 |

32 |

108 |

81 |

162 |

55.5 |

1.56 |

|

1 1/2" |

NPT |

- |

VL-S-B1-N-1000-24 |

38 |

118 |

85 |

180 |

60 |

1.86 |

|

2" |

NPT |

- |

VL-S-B1-N-1000-32 |

50 |

144 |

92 |

180 |

75 |

2.98 |

|

2 1/2" |

NPT |

- |

VL-S-B1-N-1000-40 |

65 |

180 |

115 |

224 |

94 |

6.65 |

|

3" |

NPT |

- |

VL-S-B1-N-1000-48 |

80 |

209 |

130 |

242 |

100 |

10.07 |

|

4" |

NPT |

- |

VL-S-B1-N-1000-64 |

- |

- |

- |

- |

123 |

17.79 |

|

1/4" |

SW |

- |

VL-S-B3-SW-1000-04 |

10 |

66 |

45 |

100 |

- |

0.30 |

|

3/8" |

SW |

- |

VL-S-B3-SW-1000-06 |

12 |

66 |

45 |

100 |

- |

0.30 |

|

1/2" |

SW |

- |

VL-S-B3-SW-1000-08 |

15 |

73 |

53 |

104 |

33 |

0.51 |

|

3/4" |

SW |

- |

VL-S-B3-SW-1000-12 |

20 |

79.5 |

58 |

118 |

39.5 |

0.73 |

|

1" |

SW |

- |

VL-S-B3-SW-1000-16 |

25 |

86.5 |

68 |

145 |

43.5 |

0.91 |

|

1 1/4" |

SW |

- |

VL-S-B3-SW-1000-20 |

32 |

108 |

81 |

162 |

55.5 |

1.55 |

|

1 1/2" |

SW |

- |

VL-S-B3-SW-1000-24 |

38 |

118 |

85 |

180 |

60 |

1.85 |

|

2" |

SW |

- |

VL-S-B3-SW-1000-32 |

50 |

144 |

92 |

180 |

75 |

2.98 |

|

2 1/2" |

SW |

- |

VL-S-B3-SW-1000-40 |

65 |

180 |

115 |

224 |

94 |

3.54 |

|

3" |

SW |

- |

VL-S-B3-SW-1000-48 |

80 |

209 |

130 |

242 |

100 |

6.38 |

|

4" |

SW |

- |

VL-S-B3-SW-1000-64 |

- |

- |

- |

- |

123 |

- |

WESDOM Advantages

1.WESDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each wesdom product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All wesdom products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WESDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WESDOM has always been noticed all over the world, and trust comes from quality.

6. WESDOM has a strict quality control system

WESDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

3 PCS Threaded End ball Valve: is a ball valve that used to allow or stop the fluids flow in a pipework systems. It is designed to full bore type and come with quarter turn handle. The handle can be turn by 90 degree to set the valve in open or close position. The locking mechanism on handle is to avoid the handle accidentally turn when it is in open position or close position.

3 PCs threaded end ball valve consists of 3 pieces, the valve body and 2 pieces threaded end connection. This 3 pieces can be assembly together by using bolts to go through the bolt hole outside of threaded connection and tighten with nuts. The 2 pieces threaded end connection have to connect with threaded type pipe end before the valve body assembly on it. The valve body can be removed for repair purpose by removing the nuts and bolts, without remove the end connections. It is available in stainless steel SS316 material and come with PTFE sealing material.

3 PCS Socket Weld Ball Valve: is a valve that used to start or stop the fluids flow in a pipeline system. It is designed in full bore type and come with quarter turn handle. The handle can be turn by 90 degree to open or close the valve. The locking device on the handle is work as a locking mechanism to make sure the valve is in open position only or close position only.

3 PCs socket weld ball valve consists of 2 pieces socket weld end connection and the valve body. The valve body is assembly with the 2 pieces socket weld end connection by bolts and nuts. The 2 pieces socket weld end connection will be connect to plain end type pipe end before the body assembly on it. The valve body can be removed for cleaning purpose without remove the 2 welded end connection. This ball valve is available in stainless steel SS316 material and with PTFE sealing material.

3 PCS Butt Weld Ball Valve: is a full bore type ball valve that installed on pipeline to allow or stop the fluids flow. It consists of 3 pieces, 2 pieces with butt weld connection end and the valve body. The 2 pieces with butt well end connection is assembly to the valve body with bolts and nuts. The 2 pieces butt well end connection need to connect to butt weld type pipe end first before attached with valve body. The valve body can be removed for maintenance purpose without the need to remove the welded connection end. It is available in stainless steel SS316 material and with PTFE seat.

Case:

WESDOM Group specializes in pipeline fluid systems: R&D, production and sales of valves, pipe fittings, water meters, flow meters, etc. The products cover cast iron, cast steel, stainless steel, copper, plastics and other materials, which are widely used in hydropower stations, heat, buildings, Water supply and drainage, petroleum, chemical industry, electric power, medical and other fields.

Why more and more customers are choosing wesdom valves:

1. There is a professional technical team, and quality is guaranteed

2. Independent factory, more favorable price

3. Extensively trained employees are well-versed in all aspects of flow control technology

Application:

Three-piece ball valves are commonly used in a variety of industrial applications where tight shut-off and high flow rates are required. Some specific applications where three-piece ball valves are commonly used include:

1. Oil and gas industry:

Three-piece ball valves are widely used in the oil and gas industry for various applications such as pipeline networks, refineries, and offshore platforms. They are used to control the flow of oil and gas and for isolation and shut-off purposes.

2. Chemical industry:

Three-piece ball valves are commonly used in the chemical industry to handle corrosive chemicals, acids, and caustics. They are designed to withstand harsh chemical environments and provide reliable and leak-free operation.

3. Water and wastewater treatment:

Three-piece ball valves are used in water and wastewater treatment plants for various applications, such as controlling the flow of water, isolating different sections of the plant, and regulating the flow of chemicals. They are preferred due to their durability, ease of maintenance, and ability to handle high flow rates.

4. Food and beverage industry:

Three-piece ball valves are used in the food and beverage industry for applications such as controlling the flow of liquids, gases, and steam. They are designed with sanitary features to ensure the highest level of cleanliness and prevent contamination.

5. Pharmaceutical industry:

Three-piece ball valves are used in the pharmaceutical industry to control the flow of liquids, gases, and steam. They are designed with sanitary features and comply with stringent industry regulations to ensure product purity and integrity.

Please fill in your procurement needs and contact information

.jpg)