Metal seat ball valve

Features:

Size: 2”-24”

Pressure Rating: PN10-PN64,150LB-600LB,10K-20K

Material: Carbon Steel,Stainless Steel

Design Standard: ASME B16.34,GB/T12237,JISB2071

Inspection Standard: API598,GB/T13927,JISB2003

Application medium: Water, Sewage, Gas

Application Temperature: 0-300℃

We're here to help:

Easy ways to get the answers you need.

Parameter:

A metal seat ball valve is a type of valve that uses a metal seat to create a tight seal between the ball and the valve body. It consists of a spherical ball with a hole in the middle and a metal seat pressed against it to form a seal. The ball is usually made of metal, such as stainless steel or brass, and the seat is made of a compatible metal or alloy.

When the valve is closed, the ball is pressed against the seat, creating a tight seal to prevent fluid flow. When the valve is opened, the ball rotates to align the hole with the flow path, allowing fluid to pass through. Metal seat ball valves are typically operated by a handle or lever that controls the rotation of the ball.

Metal seat ball valves are chosen for applications that require high pressure and temperature resistance, as well as resistance to corrosive and abrasive fluids. The metal seat provides a durable and reliable sealing mechanism, making them suitable for demanding industrial applications. They are commonly used in oil and gas, petrochemical, power generation, and chemical processing industries.

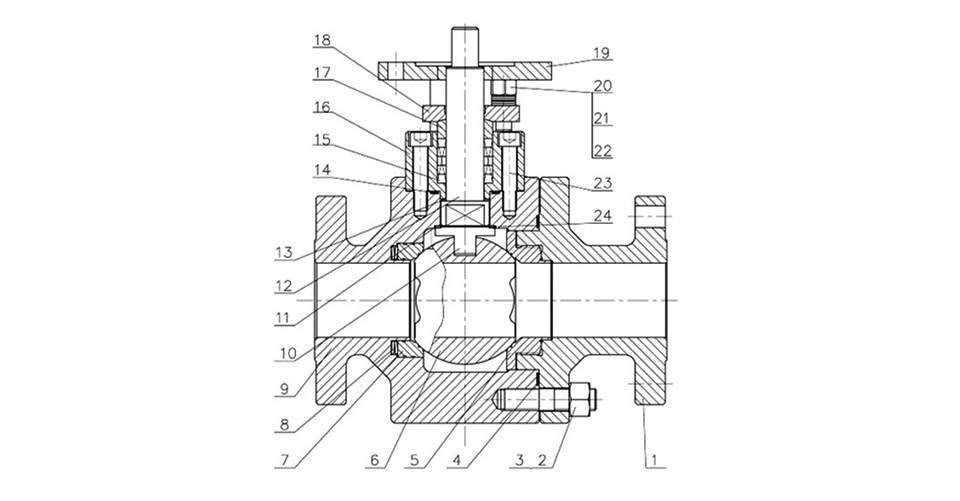

|

No. |

Name |

Materials |

No. |

Name |

Materials |

|

1 |

Secondary body |

ASTM A162 316H |

13 |

Packing |

Graphite+Metal wire |

|

2 |

Bolt |

ASTM A453 Gr.660A |

14 |

Packing gland |

ASTM A182-F316H |

|

3 |

Nut |

ASTM A194 Gr.8C |

15 |

Packing sleeve |

ASTM A182-F316H |

|

4 |

Gasket |

Graphite+Metal wire |

16 |

Packing plate |

ASTM A182-F316H |

|

5 |

Main seat |

ASTM A182-F6a+CCC |

17 |

Bracket |

ASTM A182-F316 |

|

6 |

Ball |

ASTM A182-F316H+CCC |

18 |

Bolt |

ASTM A453 Gr.660A |

|

7 |

Secondary seat |

ASTM A182-F6a+CCC |

19 |

Nut |

ASTM A194 Gr.8C |

|

8 |

Belleville spring |

Incinel 718 |

20 |

Belleville spring |

Inconel 718 |

|

9 |

Main body |

ASTM A182-F316H |

21 |

Bolt |

ASTM A453 Gr.660A |

|

10 |

Universal joint |

ASTM A638 Gr.660 |

22 |

Nut |

ASTM A194 Gr.8C |

|

11 |

Stem |

ASTM A638 Gr.660 |

23 |

Belleville spring |

Inconel 718 |

|

12 |

Packing washer |

Graphite+Metal wire |

24 |

Flat washer |

N6 |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Metal seat ball valves offer several advantages that make them a preferred choice in many industries and applications.

Here are some key advantages of metal seat ball valves:

1. Durability:

Metal seat ball valves are highly durable and can withstand harsh operating conditions, including high pressure, high temperature, and abrasive fluids. They are resistant to wear, erosion, and corrosion, making them suitable for long-term use in demanding environments.

2. Reliable sealing:

The metal seat provides a tight seal between the ball and the valve body, ensuring leak-free operation. The metal-to-metal contact creates a reliable sealing mechanism that is resistant to pressure differentials, ensuring a secure closure even under high pressures.

3. High flow capacity:

Metal seat ball valves have a full bore design, which means that the flow path through the valve is the same diameter as the pipeline. This allows for maximum flow capacity and minimal pressure drop, making them ideal for applications where high flow rates are required.

4. Versatility:

Metal seat ball valves can handle a wide range of fluids, including aggressive and corrosive substances. They are compatible with various chemicals, oils, gases, and abrasive slurries, making them suitable for diverse industrial applications.

5. Easy operation:

Metal seat ball valves are designed for easy operation and can be quickly opened or closed with a simple quarter-turn of the handle or lever. They offer smooth and precise control over the flow rate, allowing for accurate flow regulation.

6. Low maintenance:

Metal seat ball valves require minimal maintenance due to their robust construction and reliable sealing mechanism. They have a long service life and do not require frequent repairs or replacements, resulting in cost savings over time.

7. Fire-safe design:

Some metal seat ball valves are designed to meet fire-safe standards, meaning they can withstand and maintain their sealing capability even in the event of a fire. This makes them suitable for applications where fire safety is a concern.

Application:

Metal seat ball valves have a wide range of applications across various industries.

Some common applications include:

1. Oil and gas industry:

Metal seat ball valves are widely used in the oil and gas industry for controlling the flow of crude oil, natural gas, and other petroleum products. They can handle high-pressure and high-temperature conditions, making them suitable for upstream, midstream, and downstream operations.

2. Petrochemical industry:

Metal seat ball valves are used in the petrochemical industry for regulating the flow of various chemicals, solvents, and gases. They can withstand corrosive and aggressive substances commonly found in petrochemical processes.

3. Power plants:

Metal seat ball valves are essential in power plants for controlling the flow of steam, water, and other fluids. They are used in applications such as boiler feedwater control, turbine bypass, and cooling water systems due to their ability to handle high-pressure and high-temperature conditions.

4. Mining industry:

Metal seat ball valves are utilized in the mining industry for controlling the flow of slurries, tailings, and other abrasive materials. They are designed to handle the harsh conditions and abrasive particles frequently encountered in mining operations.

5. Water and wastewater treatment:

Metal seat ball valves find applications in water and wastewater treatment plants for regulating the flow of water, chemicals, and other fluids. They are resistant to corrosion and can handle the various chemicals used in the treatment processes.

6. Chemical industry:

Metal seat ball valves are used in the chemical industry for controlling the flow of various chemicals and corrosive substances. They are designed to handle aggressive fluids and can maintain a tight seal even in demanding chemical processes.

7. Food and beverage industry:

Metal seat ball valves are suitable for applications in the food and beverage industry where the flow of liquids and gases needs to be controlled. They are designed to meet hygienic requirements and can handle food-grade materials.

Please fill in your procurement needs and contact information

.jpg)