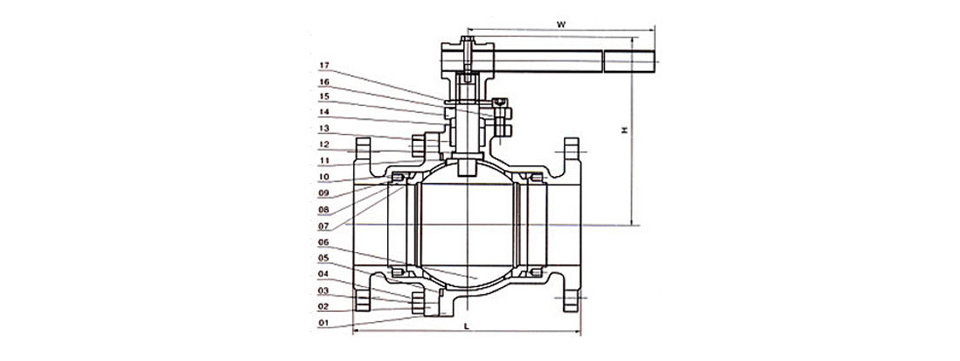

PTFE seat flanged ball valve

Features:

Size: DN15-DN300

Pressure Rating: PN16

Material: WCB

Design Standard: API608,GB/T12237

Inspection Standard: API598,GB/T13927

Application medium: Water, steam, oil

Application Temperature: -20℃~150℃

We're here to help:

Easy ways to get the answers you need.

Parameter:

A PTFE seat flanged ball valve is a type of ball valve that has a seat made of PTFE (polytetrafluoroethylene). PTFE is a synthetic fluoropolymer known for its excellent chemical resistance, low friction, and high-temperature resistance. The seat is the component that forms a seal against the ball to control the flow of fluid through the valve.

The flanged design of the valve refers to the connection type, where the valve has flanges on each end that allows for easy installation and connection to the pipeline. Flanges provide a secure and leak-proof connection by bolting the valve to the corresponding flanged ends of the pipes.

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

The combination of a PTFE seat and a flanged design offers several advantages:

1. Chemical resistance:

PTFE is highly resistant to a wide range of chemicals, making it suitable for handling corrosive and aggressive fluids. The PTFE seat provides a reliable seal and ensures compatibility with a variety of chemicals.

2. Low friction:

PTFE has a low coefficient of friction, which reduces the operating torque required to open or close the valve. This allows for smooth and easy operation of the valve.

3. High-temperature resistance:

PTFE can withstand high temperatures without losing its sealing properties or degrading. This makes PTFE seat flanged ball valves suitable for applications with elevated temperatures.

4. Leakage prevention:

When properly installed and bolted to the pipeline, the flanged design of the valve provides a secure and leak-proof connection. This ensures that there is no leakage of fluid through the valve.

5. Easy installation:

The flanged ends of the valve allow for easy installation and connection to the pipeline. The flanges can be bolted together, providing a robust and reliable connection.

Case:

WEIZIDOM Group specializes in pipeline fluid systems: R&D, production and sales of valves, pipe fittings, water meters, flow meters, etc. The products cover cast iron, cast steel, stainless steel, copper, plastics and other materials, which are widely used in hydropower stations, heat, buildings, Water supply and drainage, petroleum, chemical industry, electric power, medical and other fields.

Why more and more customers are choosing wesdom valves:

1. There is a professional technical team, and quality is guaranteed

2. Independent factory, more favorable price

3. Extensively trained employees are well-versed in all aspects of flow control technology

Application:

PTFE seat flanged ball valves have a wide range of applications in industries where chemical resistance, high-temperature resistance, and reliable sealing are required.

Some common applications include:

1. Chemical processing:

PTFE seat flanged ball valves are widely used in the chemical processing industry for handling corrosive chemicals, acids, and solvents. The PTFE seat provides excellent chemical resistance, ensuring a reliable seal and preventing leakage.

2. Pharmaceutical industry:

PTFE seat flanged ball valves are suitable for pharmaceutical applications where hygienic conditions and chemical compatibility are crucial. They are used for controlling the flow of pharmaceutical ingredients, solvents, and other fluids.

3. Water and wastewater treatment:

PTFE seat flanged ball valves are used in water and wastewater treatment plants for controlling the flow of various chemicals, acids, and corrosive substances. They are resistant to chemical attack and maintain a tight seal even in harsh environments.

4. Petrochemical industry:

PTFE seat flanged ball valves find applications in the petrochemical industry for controlling the flow of aggressive chemicals, solvents, and gases. They can withstand the high temperatures and corrosive nature of petrochemical processes.

5. Food and beverage industry:

PTFE seat flanged ball valves are used in the food and beverage industry for controlling the flow of liquids and gases. They are designed to meet hygienic requirements and can handle food-grade materials.

6. Power plants:

PTFE seat flanged ball valves are utilized in power plants for controlling the flow of steam, condensate, and other fluids. The PTFE seat provides high-temperature resistance, ensuring reliable sealing in high-temperature applications.

7. Oil and gas industry:

PTFE seat flanged ball valves are used in the oil and gas industry for controlling the flow of corrosive fluids, gases, and chemicals. They can handle high-pressure and high-temperature conditions encountered in upstream, midstream, and downstream operations.

Please fill in your procurement needs and contact information

.jpg)