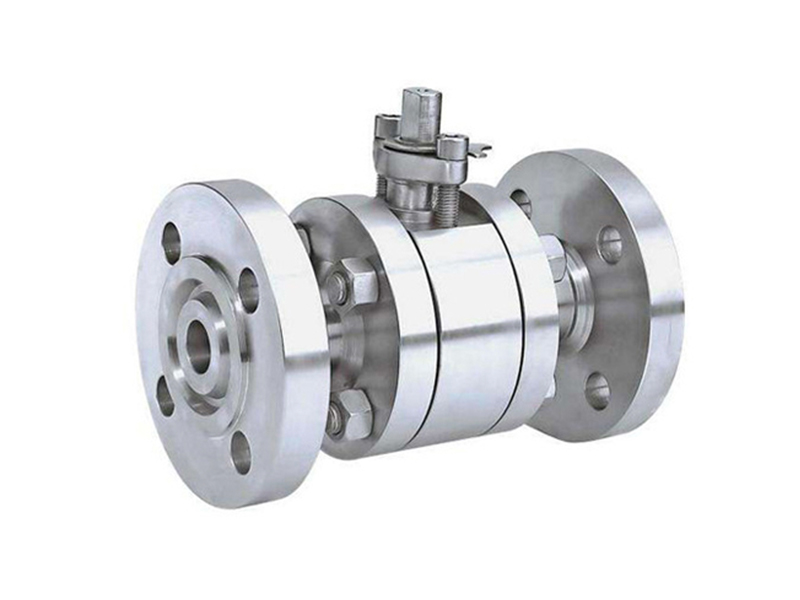

Fixed ball valve

Features:

Size: 2”~32”

Pressure Rating: PN10-PN64,150LB-600LB

Material: Carbon Steel,Stainless Steel

Design Standard: API6D,API608,GB/T12237

Inspection Standard: API598,GB/T13927

Application medium: Water,Oil ,Gas

Application Temperature: -29~300℃

We're here to help:

Easy ways to get the answers you need.

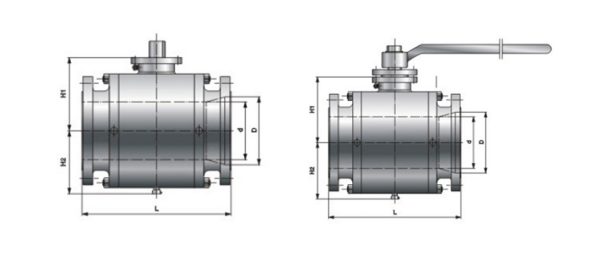

Parameter:

A fixed ball valve is a type of valve that uses a ball with a hole through the middle to control the flow of fluid. The ball has a fixed position within the valve body and is rotated by a handle or actuator to open or close the valve. When the ball is rotated so that the hole aligns with the flow path, fluid can pass through the valve, and when the ball is rotated to block the flow path, the valve is closed. Fixed ball valves are commonly used in various industries for their durability, reliability, and ease of operation.

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

Quality Control Process

Standards&Features:

Design features:

1. Structure form:

Floating structure, fixed structure, single seat bi-directional seal powder structure;

2. Bidirectional sealing structure design

3. Stem anti-jet structure

4. Sealing performance to ANSI B16.104 CLASS VI and zero leakage

Fixed ball valves offer several advantages, including:

1. Excellent sealing:

Fixed ball valves provide tight shut-off capabilities, ensuring minimal leakage when the valve is closed. The ball design and sealing materials offer reliable sealing even under high pressures and temperatures.

2. Smooth flow control:

The full bore design of fixed ball valves allows for unobstructed flow with minimal pressure drop. This ensures efficient and smooth flow control, reducing energy loss and system inefficiencies.

3. Durability and reliability:

Fixed ball valves are known for their robust construction and long service life. The ball and seat materials are typically chosen for their resistance to corrosion, erosion, and wear, making fixed ball valves suitable for a wide range of applications and operating conditions.

4. Easy operation:

Fixed ball valves generally have a simple design and are easy to operate. They typically feature a quarter-turn operation, where the handle or actuator is rotated by 90 degrees to open or close the valve. This quick and easy operation improves efficiency and reduces the time required for manual valve control.

5. Versatility:

Fixed ball valves are available in various materials, sizes, and pressure ratings, allowing them to be used in a wide range of applications across different industries. They can handle various fluids, including liquids, gases, and slurries.

6. Low maintenance requirements:

Due to their durable construction and reliable sealing, fixed ball valves usually require minimal maintenance. Regular inspection and lubrication can help ensure their continued performance.

7. Bi-directional flow:

Fixed ball valves can handle flow in either direction, making them suitable for applications where the flow direction may change.

Application:

Fixed ball valves find applications in various industries and systems, including:

1. Oil and gas industry:

Fixed ball valves are commonly used in oil and gas pipelines, refineries, and petrochemical plants for flow control and shut-off applications. They can handle high pressures and temperatures, making them suitable for harsh operating conditions.

2. Water and wastewater treatment:

Fixed ball valves are used in water and wastewater treatment plants for controlling the flow of water, chemicals, and sludge. They are also used in water distribution systems for residential, commercial, and industrial applications.

3. Power generation:

Fixed ball valves are employed in power plants for controlling the flow of steam, condensate, and other fluids. They are used in boiler feedwater systems, cooling water systems, and various other applications within power generation facilities.

4. Chemical and pharmaceutical industries:

Fixed ball valves are utilized in chemical processing plants and pharmaceutical manufacturing facilities for precise flow control and shut-off of corrosive chemicals, solvents, and gases.

5. HVAC systems:

Fixed ball valves are used in heating, ventilation, and air conditioning (HVAC) systems for controlling the flow of water, refrigerants, and other fluids. They help regulate temperature and maintain optimal comfort levels in buildings.

6. Food and beverage industry:

Fixed ball valves are found in food and beverage processing plants for controlling the flow of liquids, such as water, beverages, and food ingredients. They are designed to meet hygiene and sanitary requirements.

7. Pulp and paper industry:

Fixed ball valves are used in pulp and paper mills for controlling the flow of chemicals, pulp, water, and steam. They are crucial for various processes involved in paper production.

Please fill in your procurement needs and contact information

.jpg)