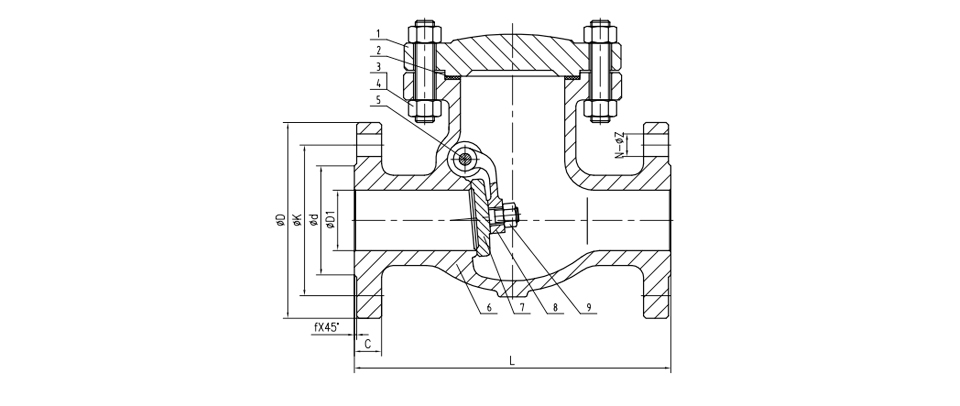

API Swing Check Valve

Features:

Product model: H44H-16C/P

Nominal DN: DN50-600

Nominal pressure: PN1.0/1.6mpa

Applicable temperature: ≤ 425℃

Applicable medium: water, oil

Body material: cast steel, stainless steel

Connection: flange

We're here to help:

Easy ways to get the answers you need.

Parameter:

Swing check valve introduction:

Swing check valves are automatically opened and closed by the force generated by the flow of the medium itself in the pipeline and belong to an automatic valve.

Check valve for pipeline system, and its main role is to prevent the backflow of media, to prevent the pump and its drive motor reversal, as well as the release of media in the container.

Check valve products can also be used to supply the auxiliary system in which the pressure may rise above the main system pressure.

| Nominal Pressure | Specifications | Size(mm) | |||||||

| PN(MPa) | inch | DN | L | D | D1 | D2 | b | Z-d | H |

| 150Lb | 1 | 25 | 127 | 108 | 79.5 | 51 | 12 | 4--15 | 90 |

| 2001/1/2 | 40 | 165 | 127 | 98.5 | 73 | 15 | 4--15 | 115 | |

| 2 | 50 | 203 | 152 | 120.7 | 92 | 16 | 4--19 | 150 | |

| 2002/1/2 | 65 | 216 | 177.8 | 139.7 | 104.7 | 18 | 4--19 | 160 | |

| 3 | 80 | 241 | 190.5 | 152.4 | 127 | 19 | 4--19 | 180 | |

| 4 | 100 | 292 | 229 | 190.5 | 157 | 24 | 8--19 | 220 | |

| 5 | 125 | 330 | 254 | 216 | 185.7 | 26 | 8--22 | 280 | |

| 6 | 150 | 356 | 279 | 241.3 | 216 | 26 | 8--22 | 340 | |

| 8 | 200 | 495 | 343 | 298.5 | 270 | 29 | 8--22 | 400 | |

| 10 | 250 | 622 | 406 | 362 | 324 | 31 | 12--25 | 460 | |

| 12 | 300 | 698 | 483 | 432 | 381 | 32 | 12--25 | 530 | |

| 14 | 350 | 787 | 533 | 476.3 | 413 | 35 | 12--29 | 580 | |

| 16 | 400 | 864 | 597 | 540 | 470 | 37 | 16-29 | 600 | |

| 18 | 450 | 978 | 635 | 578 | 533.4 | 40 | 16-32 | 650 | |

| 20 | 500 | 978 | 698.5 | 635 | 584 | 43 | 20-32 | 700 | |

| 24 | 600 | 1295 | 813 | 749.3 | 692 | 48 | 20-35 | 780 | |

| 28 | 700 | 1448 | 927 | 863.6 | 800 | 72 | 28-35 | 850 | |

| 30 | 800 | 1524 | 984 | 914.4 | 857 | 75 | 28-35 | 920 | |

| 300Lb | 2 | 50 | 267 | 165 | 127 | 92 | 23 | 8--19 | 170 |

| 2002/1/2 | 65 | 292 | 190.5 | 149.4 | 104.7 | 26 | 8--22 | 180 | |

| 3 | 80 | 318 | 210 | 168.2 | 127 | 29 | 8--22 | 210 | |

| 4 | 100 | 356 | 254 | 200.2 | 157 | 32 | 8--22 | 290 | |

| 5 | 125 | 400 | 279 | 235 | 185.7 | 35 | 8--22 | 290 | |

| 6 | 150 | 444 | 318 | 270 | 216 | 37 | 12--22 | 350 | |

| 8 | 200 | 533 | 381 | 330 | 270 | 42 | 12--25 | 430 | |

| 10 | 250 | 622 | 445 | 387.5 | 324 | 48 | 16-29 | 480 | |

| 12 | 300 | 711 | 521 | 451 | 381 | 51 | 16-32 | 550 | |

| 14 | 350 | 838 | 584 | 514.5 | 413 | 54 | 20-32 | 620 | |

| 16 | 400 | 864 | 648 | 571.5 | 470 | 58 | 2035 | 650 | |

| 18 | 450 | 978 | 711 | 628.7 | 533.4 | 61 | 24-35 | 690 | |

| 20 | 500 | 1016 | 775 | 685.8 | 584 | 64 | 24-35 | 740 | |

| 24 | 600 | 1346 | 914.4 | 812.8 | 692 | 70 | 24-41 | 800 | |

| 28 | 700 | 1499 | 1035 | 939.8 | 800 | 86 | 28-45 | 860 | |

| 30 | 800 | 1594 | 1092 | 997 | 857 | 92 | 28-48 | 980 | |

| 600Lb | 2 | 50 | 292 | 165 | 127 | 92 | 26 | 8--19 | 190 |

| 2002/1/2 | 65 | 330 | 190.5 | 149.4 | 104.7 | 29 | 8--22 | 210 | |

| 3 | 80 | 356 | 210 | 168.2 | 127 | 32 | 8--22 | 230 | |

| 4 | 100 | 432 | 273 | 216 | 157 | 38 | 8--25 | 300 | |

| 5 | 125 | 508 | 330 | 266.7 | 185.7 | 45 | 8--29 | 310 | |

| 6 | 150 | 559 | 356 | 292 | 216 | 48 | 12--29 | 370 | |

| 8 | 200 | 660 | 419 | 349 | 270 | 56 | 12-32 | 450 | |

| 10 | 250 | 787 | 508 | 432 | 324 | 64 | 16-35 | 500 | |

| 12 | 300 | 838 | 559 | 489 | 381 | 67 | 20-35 | 570 | |

| 14 | 350 | 889 | 603 | 527 | 413 | 70 | 20-38 | 640 | |

| 16 | 400 | 991 | 686 | 603 | 470 | 77 | 20-41 | 570 | |

| 18 | 450 | 1092 | 743 | 654 | 533.4 | 83 | 20-44 | 710 | |

| 20 | 500 | 1194 | 855 | 724 | 584 | 89 | 24-44 | 760 | |

| 24 | 600 | 1397 | 1040 | 838 | 692 | 102 | 24-52 | 830 | |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

1.Valve flow is streamlined with low resistance.

2. The opening and closing part is controlled by the medium itself to prevent backflow.

3. The sealing pair is advanced and reasonable. The sealing surface of the valve disc and the valve seat is welded by iron-based alloy or silicon tartar cobalt-based carbide, so it has the advantages of wear resistance, high temperature resistance, corrosion resistance and scratch resistance. . And it has a long service life.

4. The product can be used in various pipe flange and flange standard and flange sealing types to meet various engineering needs and user requirements.

5. There are a wide variety of valve bodies. Gaskets can be reasonably matched to the actual situation or user requirements and can be applied to a variety of pressure, temperature and media conditions.

6.The structure length is short, its structure length is only the traditional flange check valve 1/4~1/8.

7.Small size, light weight, its weight is only the traditional flange check valve 1/4~1/20.

8.The valve flap closed fast, water hammer pressure is small.

9.Horizontal pipe or vertical pipe can be used, convenient installation.

10.The flow channel is unobstructed, the fluid resistance is small.

11.Sensitive action, good sealing performance.

12.Short stroke, close the impact force is small.

13.The overall structure is simple and compact, beautiful appearance.

14.Long service life, reliable performance.

Application:

Swing check valve application range:

Flange type swing check valve is suitable for pressure PN16 ~ 160 working temperature -29 ℃ ~ 550 ℃ petroleum, chemical, pharmaceutical, fertilizer, electric power industry and other working conditions of the pipeline, swing check valve applicable media for water, oil, steam, acidic media, etc.

Please fill in your procurement needs and contact information