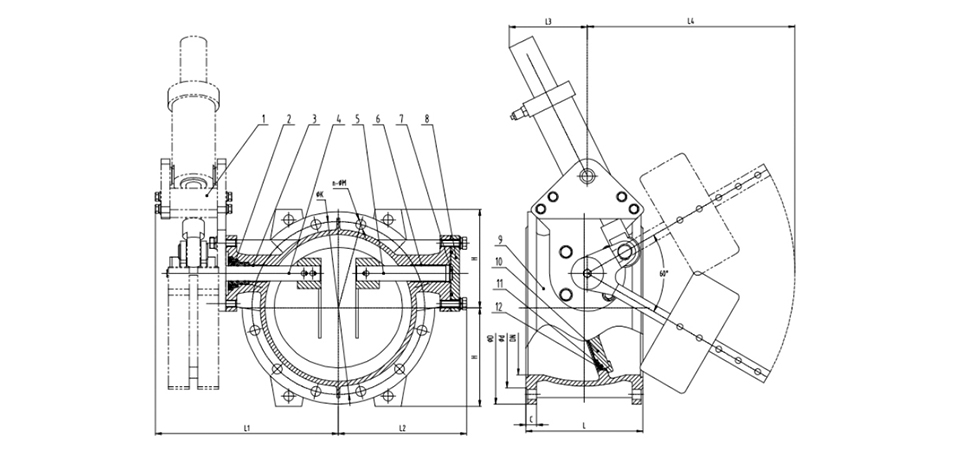

DN800 Slow closing check valve

Features:

Size: DN300-DN1000

Pressure Rating: PN16/PN25

Material: Ductile Iron

Design Standard: DIN3352 F4, LIGHT TYPE

Inspection Standard: EN12266

Application medium: Drinking water, sewage, seawater, irrigation or other neutral liquid

Application Temperature: -40°C~150°C

We're here to help:

Easy ways to get the answers you need.

Parameter:

Brief introduction of rubber disc check valve:

Slow-closing check valve also known as butterfly cushion check valve, oblique bridge soft seal slow close check valve seat adopt bevel type, large eccentric design, external or built-in buffer system, is my company independent research and development,with independent intellectual property rights of patented products. Mainly installed in the pump export and medium deep place,prevent the backflow medium, automatic eliminate the destructive water hammer,protect the safety of water pump and pipeline. It is mainly composed of valve body, valve plate,buffer system. Structure is novel, the closing of the valve plate short journeys, smooth operation, low energy consumption in medium under the action of buoyancy open closed,is a new generation of energy saving and consumption reducing and environmental protection products.

| DN | ød | øD | øK | n-øM | H | C | L | L1 | L2 | L3 | L4 |

| 300 | 370 | 460 | 410 | 12-ø28 | 230 | 24.5 | 270 | 425 | 300 | 180 | 460 |

| 350 | 429 | 520 | 470 | 16-ø28 | 260 | 26.5 | 290 | 470 | 345 | 180 | 460 |

| 400 | 480 | 580 | 525 | 16-ø31 | 290 | 28 | 310 | 545 | 377 | 185 | 570 |

| 450 | 548 | 640 | 585 | 20-ø31 | 315 | 30 | 330 | 565 | 400 | 185 | 570 |

| 500 | 609 | 715 | 650 | 20-ø34 | 340 | 31.5 | 350 | 660 | 470 | 220 | 600 |

| 600 | 720 | 840 | 770 | 20-ø37 | 395 | 36 | 390 | 710 | 520 | 220 | 600 |

| 700 | 794 | 910 | 840 | 24-ø37 | 460 | 39.5 | 430 | 810 | 580 | 230 | 760 |

| 800 | 901 | 1025 | 950 | 24-ø41 | 520 | 43 | 470 | 863 | 525 | 230 | 760 |

| 900 | 1001 | 1125 | 1050 | 28-ø41 | 565 | 46.5 | 510 | 961 | 660 | 340 | 950 |

| 1000 | 1112 | 1255 | 1170 | 28-ø43 | 625 | 50 | 550 | 1021 | 720 | 340 | 950 |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Design Standard: DIN3352 F4, LIGHT TYPE

Inspection Standard: EN12266

Advantages of slow closing check valve:

Adopt bevel type seat, easy to open, open valve in low velocity of fluid mechanics;

Close short journeys, required to reduce energy consumption, reducing the media on the impact of the valve and valve seat and the water hammer wave in pipe;

According to the working conditions of the scene, there are built-in and built-out buffer device to choose from;

Novel and reasonable structure of the valve. Body with to prevent excessive open the limit of structure, the valve plate adopts the whole suspension stream line structure rigidity, small flow resistance, smooth operation,low noise;

With the opening indicating device, the valve open intuitive visual;

Seat USES the taper sealing,reliable sealing, long service life;

According to the condition and medium hard seal soft seal(H)(x) to choose from. Generally choose sot seal, zero leakage, buffer voice closed small; But medium for sewage or containing particles, and the solid impurities such as sand, advised to choose a hard seal, improve the service life of the valve;

Adopting direct stroke cylinder cylinder replacement back transformation,more reliable structure, ensure the operation of the valve more easy smooth, no resistance;

With a standard interface of buffer device, and strictly to ensure interchangeability so in production, installation, maintenance, replacement, transportation process, is more convenient.

Application:

The slow-closing check valve is an advanced, intelligent hydraulic valve that is being used more and more widely in various industries.

The main applications are in the following areas:

1. Wastewater treatment:

Slow-closing check valves can be used in water treatment systems to prevent wastewater backflow and back-tide, ensuring a complete and flawless water treatment system.

2. Fire fighting systems:

In fire fighting systems, slow closing check valves prevent sewage or fire fighting foam from flowing back from the fire fighting pipes to the fire fighting tank or city water network.

3. Industrial applications:

Slow-closing check valves can be used in a variety of industrial piping systems such as petrochemical, pharmaceutical, and energy to protect equipment and pipelines from high pressure and

contamination.

4. Automation:

Slow-closing check valves are used in automation equipment to control fluid flow and to avoid damage caused by fluid backflow.

5. Construction:

In construction, slow-closing check valves can be connected to cast steel, cast iron, and organic pipework to maintain the flow of water and avoid pipework hazards.

Please fill in your procurement needs and contact information