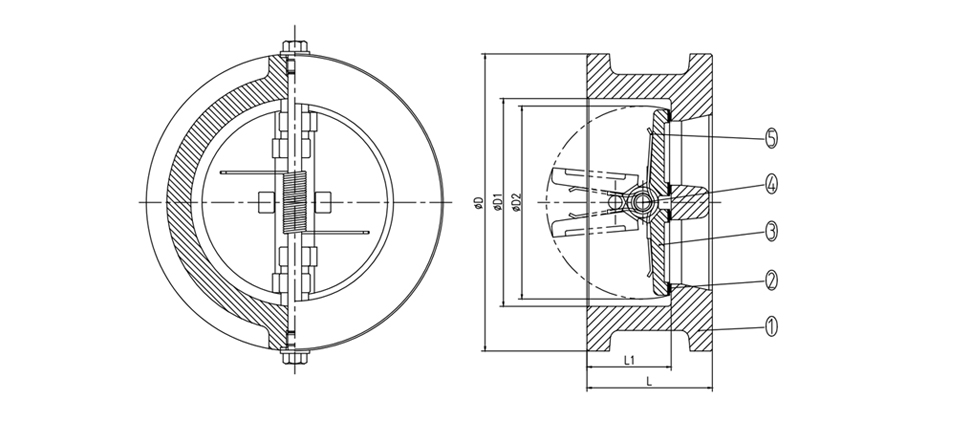

Wafer Check Valve

Features:

DN: 2~24"(DN50~DN400)

Nominal pressure (MPa): PN10, PN16,

Body Materials: Ductile Iron , WCB , Stainless Steel

Seat Materials: NBR, EPDM

Disc Materials: Ductile Iron, WCB, CF8,CF8M, Al-bronze C958

Stem Materials: SS416, SS304, SS316

We're here to help:

Easy ways to get the answers you need.

Parameter:

What is a wafer dual plate check valve?

The dual plate check valve is a general purpose check valve that is stronger, lighter in weight and smaller in size than traditional swing check valves.

The dual plate check valve utilizes two spring-loaded plates attached to a central dumpling chain pin. When the flow is reduced, the plates are closed by the action of the torsion spring, and there is no need for reverse flow.

This design provides the dual advantages of no water hammer and no impact at the same time.

Consisting of 2 discs attached to the valve body by a pin and operated by the action of springs, which immediately start closing the valve, when the fluid stops, dual plate check valves are used to prevent back flow and also work as a prevention for water hammer.

Dual Plate Check Valves are made from a wide range materials including cast iron, special stainless steels, ect. They can be soft seat or metal seat construction and also have the ability to adjust the spring torque according to the application, which makes it a product suitable for general and special purposes.

|

DN |

NPS |

L±1.5 |

D |

D1 |

D2 |

|

50 |

2'' |

43 |

101 |

58 |

65 |

|

65 |

2 1/2'' |

46 |

118 |

75 |

80 |

|

80 |

3'' |

64 |

132 |

85 |

94 |

|

100 |

4'' |

64 |

157 |

105 |

117 |

|

125 |

5'' |

70 |

186 |

125 |

145 |

|

150 |

6'' |

76 |

213 |

165 |

170 |

|

200 |

8'' |

89 |

272 |

215 |

224 |

|

250 |

10'' |

114 |

328 |

260 |

265 |

|

300 |

12'' |

114 |

378 |

300 |

310 |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Design standard:

API 594/API 6D standard

Inspection and testing standard:

API 598

Flange to flange distance:

According to ANSIBAPl 594/API 6D/ANSI B 16.10

Advantages of wafer dual plate check valve:

#1 Lightweight, so easier to handle and self-supporting. More compact and well-structured design.

#2 The same valve can be installed horizontally or vertically.

#3 Due to the spring assisted closing, only the double plate check valve can be installed upside down.

#4 Reduced pressure drop and energy loss regardless of pressure rating.

#5 Efficient and reliable sealing under most flow and pressure conditions.

#6 The valve closes before the flow reverses and the velocity is zero.

#7 Water hammer is almost non-existent.

#8 Long service life and trouble-free operation.

#9 Small in size, light in weight, compact in structure,easy in maintenance.

#10 Two torsion springs are used excreting on each of the pair valve plates,which close the plates quickly and automatically.

#11 The quick-close action prevents the medium from flowing back and eliminates water hammer effect.

#12 Short body structure length and good rigidity.

#13 This valve is tightly sealed, without leakage under the pressure water test.

#14 Safe and reliable in operation,high interference-resistance.

Case:

WEIZIDOM Group specializes in pipeline fluid systems: R&D, production and sales of valves, pipe fittings, water meters, flow meters, etc. The products cover cast iron, cast steel, stainless steel, copper, plastics and other materials, which are widely used in hydropower stations, heat, buildings, Water supply and drainage, petroleum, chemical industry, electric power, medical and other fields.

Why more and more customers are choosing wesdom valves:

1. There is a professional technical team, and quality is guaranteed

2. Independent factory, more favorable price

3. Extensively trained employees are well-versed in all aspects of flow control technology

Application:

Applicaton of wafer dual plate check valve:

1.Water Treatment Plant ;

2.Drilling Rigs;

3.Paper Industry;

4.Gas Plant;

5.Sugar Industry;

6.Cooling Water Circulation;

7.Breweries;

8.Heating & Air Conditioning;

9.Chemical Industry;

10.Pneumatic Conveyors;

11.Waste Effluent Treatment Plant;

12.Compressed Air.

Please fill in your procurement needs and contact information