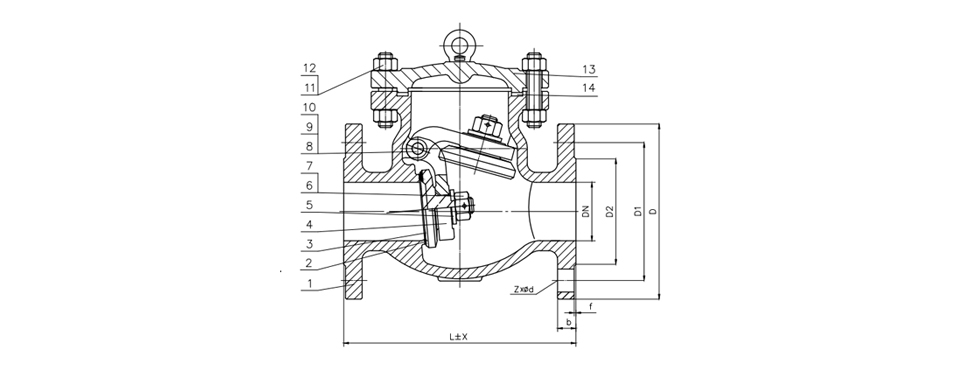

DIN Flange check valve

Features:

Product model: H44H-16C/P

Nominal DN: DN50-600

Nominal pressure: PN1.0/1.6mpa

We're here to help:

Easy ways to get the answers you need.

Parameter:

|

Nominal DN(mm) |

L |

D |

D1 |

D2 |

b-f |

Z-Фd |

H |

|

40 |

200 |

145 |

110 |

85 |

18-3 |

4-Ф18 |

110 |

|

50 |

230 |

160 |

125 |

100 |

20-3 |

4-Ф18 |

120 |

|

65 |

290 |

180 |

145 |

120 |

20-3 |

4-Ф18 |

130 |

|

80 |

310 |

195 |

160 |

135 |

22-3 |

4-Ф18 |

140 |

|

100 |

350 |

215 |

180 |

155 |

22-3 |

8-Ф18 |

170 |

|

125 |

400 |

245 |

210 |

185 |

24-3 |

8-Ф18 |

192 |

|

150 |

480 |

280 |

240 |

210 |

24-3 |

8-Ф23 |

215 |

|

200 |

495 |

335 |

295 |

265 |

26-3 |

8-Ф23 |

240 |

|

250 |

600 |

390 |

350 |

320 |

28-3 |

12-Ф23 |

265 |

|

300 |

698 |

440 |

400 |

368 |

28-4 |

12-Ф23 |

350 |

|

350 |

800 |

500 |

460 |

428 |

30-4 |

16-Ф23 |

405 |

|

400 |

900 |

565 |

515 |

482 |

32-4 |

16-Ф25 |

430 |

|

500 |

978 |

670 |

620 |

585 |

34-4 |

20-Ф25 |

480 |

|

600 |

1295 |

780 |

725 |

685 |

36-5 |

20-Ф31 |

622 |

WEIZIDOM Advantages

1.WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

2.The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

3.Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

4.One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

5.WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

6. WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

Quality Control Process

Standards&Features:

Features of DIN flange check valve:

1. Valve flow is streamlined with low resistance.

2. The opening and closing part is controlled by the medium itself to prevent backflow.

3. The sealing pair is advanced and reasonable. The sealing surface of the valve disc and the valve seat is welded by iron-based alloy or silicon tartar cobalt-based carbide, so it has the advantages of wear resistance, high temperature resistance, corrosion resistance and scratch resistance. . And it has a long service life.

4. The product can be used in various pipe flange and flange standard and flange sealing types to meet various engineering needs and user requirements.

5. There are a wide variety of valve bodies. Gaskets can be reasonably matched to the actual situation or user requirements and can be applied to a variety of pressure, temperature and media conditions.

Case:

WEIZIDOM Products applied in Bangladesh one Mining project. Accoridng to client critical working condition, WESDOM customized solutions for client project. Now all products have well installed on site and get good feedback from clients.

Main applied products as following:

Foot Valves, Check Valves and Motorized gate valves.

Application:

1.Suitable for oil

2.Chemical

3.Chemical fertilizer

4.Chemical fertilizer

5.Power industry and other working conditions of the pipeline.

Please fill in your procurement needs and contact information