Bellows Compensator (Expansion Joint) for Pipelines: Function, Selection & Installation Guide

Quick summary: Bellows compensators (metal expansion joints) absorb thermal expansion, correct misalignment and isolate vibration in pipelines. This technical guide explains types, materials, selection steps and installation best practices to help engineers choose the right expansion joint for reliable pipeline operation.

What is a bellows compensator?

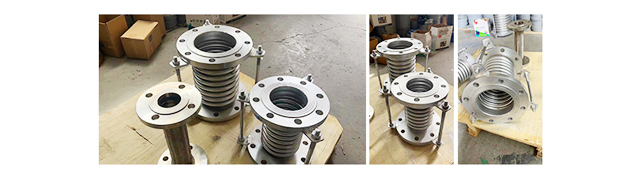

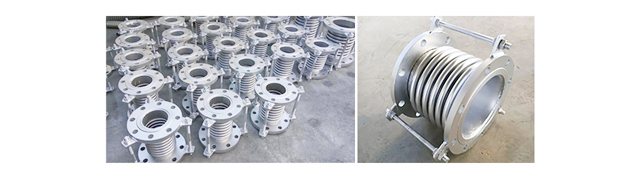

A bellows compensator (often called a bellows expansion joint) is a flexible pipeline component built around a corrugated metal or non-metal element—referred to as the bellows. The bellows element connects two pipe ends and can compress, extend or bend to absorb movements caused by thermal expansion, vibration or misalignment. Typical end connectors include weld ends, flanges or spigots, and many assemblies include guides, anchors and tie rods to control movement.

How bellows compensators work (working principle)

The bellows geometry—concentric corrugations—permits elastic deformation. When a pipeline heats up and lengthens, an axial bellows compresses or extends to absorb that length change. When the system shifts sideways, a lateral bellows flexes to accommodate the offset. Angular bellows permit rotation between sections. Pressure-balanced bellows designs incorporate internal balancing elements to reduce or neutralize pressure thrust, enabling freer movement without massive anchors.

Key functions & benefits:

* Thermal compensation: Relieves thermal stress in long runs and steam/flue ducts.

* Vibration isolation: Damps mechanical vibration from pumps, fans and compressors.

* Alignment correction: Compensates for installation tolerances and minor misalignments.

* Seismic/settlement protection: Absorbs ground movement or structural settlement.

* Noise reduction: Special lined or non-metallic joints help reduce transmitted noise.

Types of bellows compensators

Understanding the movement you need to absorb is the first step in choosing the right type:

| Type | Movement Mode | Typical Application |

| Axial bellows | Axial compression/extension | Long straight runs, thermal growth |

| Lateral bellows | Transverse displacement | Offset compensation, flexible bends |

| Angular bellows | Rotation/angle | Flanged offsets, duct changes |

| Pressure-balanced bellows | Neutralizes pressure thrust | Boiler and turbine piping, long unsupported spans |

| Non-metallic (rubber/PTFE) | Flexible & damping | Chemical lines, noise reduction |

Material & lining considerations

Choose bellows materials that match the process conditions:

* Alloy steels (e.g., Inconel, Alloy 800) – high temperature and corrosive flue gas.

* PTFE liners – aggressive chemicals where metal diffusion is a concern.

* Rubber or composite – excellent damping and lower cost for low-temperature applications.

Note: Non-metallic joints may limit temperature/pressure. For steam or high-pressure service, favor metal bellows or PTFE-lined metal bellows.

How to select the right bellows compensator

Provide the following data to your supplier to ensure correct sizing and long life:

* Design and operating pressure

* Maximum operating temperature

* Calculated thermal displacements (axial, lateral, angular)

* Pipe diameter and wall schedule

* Installation constraints: straight lengths, supports, anchors

When in doubt, request a stress and movement calculation from the manufacturer. Pressure-balanced or tie-rod assemblies are recommended when internal pressure thrust would otherwise require massive anchoring.

Installation best practices

Follow these installation steps to avoid premature failures:

* Install recommended guide and anchor points per the layout — do not let the bellows carry pipeline weight.

* Observe manufacturer-recommended upstream and downstream straight lengths to prevent flow turbulence stress.

* Use travel stops when movement may exceed rated travel.

* Pressure test after installation (with proper venting) and then drain/dry fully to avoid trapped water corrosion.

Common failure modes & maintenance

Typical bellows issues include fatigue cracking near corrugation roots, corrosion, and flange/gasket leakage.

Mitigation steps:

* Choose corrosion-resistant alloys or liners when media is aggressive.

* Perform regular visual inspections, leak checks and movement measurements.

* Replace bellows at recommended life or when any defect is detected—do not attempt extended temporary repairs on fatigued bellows.

Applications & use cases

Bellows compensators are used across industries:

* Boiler flues & power plants – handle thermal cycling and pressure thrust.

* Chemical processing – PTFE-lined bellows for chemical resistance.

* Marine & shipbuilding – absorb vibration and hull flexing.

Case highlight: Installing pressure-balanced bellows in a boiler flue line removed the need for complex anchors and reduced maintenance intervals by 30% in a mid-size plant.

FAQ — Frequently Asked Questions

Q: Can bellows compensators handle internal pressure thrust?

A: Yes — pressure-balanced designs are specifically built to neutralize pressure thrust so that anchors and supports can be simplified. For unbalanced bellows, proper anchoring is essential.

Q: How often should bellows be inspected?

A: At minimum annually for normal service. In high-cycle or corrosive environments, inspect quarterly or per manufacturer guidance.

Q: Metal bellows vs rubber expansion joint — which to choose?

A: Choose metal bellows for high temperature/pressure and where fatigue resistance is required; choose rubber or composite for noise damping, flexibility and corrosive resistance at lower temperatures.

Conclusion & Call to Action

A correctly selected and installed bellows compensator is a cost-effective tool to protect pipelines from thermal stress, vibration and misalignment. It reduces downtime, lowers maintenance costs and extends equipment life.

If you need project-specific selection, WEIZIDOM offers stainless steel bellows, PTFE-lined options and pressure-balanced designs with engineering support, movement calculations and datasheets.