- Gate valve

-

- BS5163 rising stem soft seal gate valveDN1000 Extension stem double flange soft seal gate valveWEIZIDOMDIN F4 resilient seated gate valveDN450-1200 Resilient Seated Gate ValveDIN F5 resilient seated gate valveSocket connection soft seal gate valveWEIZIDOMUnderground cap soft seal gate valveHard seal gate valveAPI slab Gate ValveStainless steel flange gate valveWafer knife gate valvePneumatic gate valveSoft seal gate valveExtension stem gate valveUL/FM fire protection groove ends gate valveRising stem forged steel gate valvecarbon steel gate valveStainless steel threaded gate valveDIN soft seal gate valveANSI soft sealing gate valve 200PSICast iron gate valveBS resilient seated gate valve

- Butterfly valve

-

- DN900 pneumatic triple eccentric hard seal butterfly valveD643H Triple Eccentric Butterfly ValveD343H Hard seal butterfly valveMulti standard EPDM seated butterfly valveSingle flange butterfly valveDN2000 Double eccentric butterfly valveFlange butterfly valveLug butterfly valveWafer butterfly valve with handleWorm gear operated butterfly valveWafer lined fluorine butterfly valveStainless steel wafer butterfly valveStainless steel flanged butterfly valveThree eccentric flange butterfly valvePneumatic flanged butterfly valvePneumatic wafer butterfly valveTriple eccentric butterfly valve wafer typeWafer butterfly valve ULC approvedInflatable seat butterfly valveHigh performance butterfly valveGrooved end butterfly valveElectric soft seal butterfly valveFlange fluorine lined butterfly valveHandle aluminum butterfly valveWorm Gear Aluminum Butterfly ValveFull PTFE lined butterfly valve wafer typeOne stem no-pin wafer butterfly valveMulti standard aluminum stem butterfly valveStainless Steel wafer Butterfly ValveAluminium handle operated lug butterfly valveLever Operated Flange Butterfly ValveButterfly valve stemButterfly valve discButterfly valve seat

- Ball valve

-

- DN1400 top-mounted eccentric semi-ball valveFlanged three-way ball valveFully welded ball valveNatural gas ball valveHigh platform flange ball valve1 PC ball valveFixed ball valvePTFE seat flanged ball valveMetal seat ball valveAPI 6D ball valve3 Piece ball valveFull Bore 3 way ball valve L-Port3 Way T-Port ball valve2PC Ball valve female thread stainless steel

- Globe Valve

-

- API Carbon Steel Globe ValveBellows Globe ValveStainless steel flange globe valveStainless steel thread S type globe valveStainless steel thread B type globe valveCast Steel Globe ValvePiston Globe ValveWCB Carbon Steel Globe Check Valveelectric motorized control stainless steel SS316 globe valveBrass Globe ValveCryogenic Globe valveHT200 Globe ValveThreaded Stainless Steel Globe ValveGG25 Globe ValveANSI API Cast Steel And Stainless Steel Globe valve

- Check valve

-

- Rubber seal check valveDN800 Slow closing check valveDN800 Rubber Disc Check ValveButterfly Buffering Check Valvecheck valve with counter weightSilent Check ValveWCB Swing check valveSwing Check ValveSingle Chip Check Valve H74WStainless Steel Wafer Check ValveSwing Start Check ValveFoot check valveAPI Swing Check ValveDIN Flange check valveSingle plate check valveLifting Check ValveBottom ValveHammer Diminish Noises Check ValveWafer Check ValveWafer dual plate check valve

- Control valve

-

- Static Balancing ValveCage Guided Sleeve Globe Control ValveDN1000 Piston Flow Regulating ValveDN1600 Electric Actuator Flow Regulating ValvePneumatic Flanged Butterfly ValvePneumatic Wafer Butterfly ValveAngle Seat ValvePneumatic gate valveElectric three-way control valveElectric sleeve control valve

- Water Meter

-

- Vertical Type Water MetersStainless steel threaded water meterPiston water meterPlastic water meterMore flow rotor dry water meterspiral vane flange water meterCI wotlman water meter with pulse outputLXCLG(R) Vertical removable element woltman cold (hot) water meterSingle flow rotor dry water meterPrepaid Token Water MeterElectromagnetic flowmeterRotary Piston Liquid Sealed Water MeterRotary Piston Liquid Sealed Water Meter

- Air valve

-

- Double ball exhaust valveDoubleair Air Valve SaudiDoubleair Air Valve Southeast AsiaDoubleair Air Valve South AmericaDouble Air ValveThreaded Air ValveSingle Air ValveTriple Functions Air ValveAutomatic Air Release ValveAutomatic release valveAutomatic exhaust valveComposite Exhaust Air ValveBrass exhaust valveDouble Ball Air Valve

- Pipe Repair & Coupling

-

- Flexible Multi-Function Pipe Coupling ZFJ-SSS Semi-Circle Pipe Repair Clamp SJW-HDuctile Iron Band Repair ClampStainless Steel Band Repair ClampDouble-Section Pipe Repair CouplingFolding Type Pipe RepairSingle-Section Multi-Function Pipe Coupling MF-SGear-Ring Type Multi-Function Pipe Coupling GR-SZBW Damping Corrugated Hose

- Dismantling Joint

-

- VSSJAFC(CC2F) Detachable Flange Transmission JointVSSJA-2(B2F) Double Flange Limited Expansion JointVSSJA-1(BF) Single Flange Limited Expansion JointVSSJA(AF) Flange Loose Expansion JointJGD-B Threaded Rubber JointZBW Damping Corrugated HoseKXT-S Flexible Dual-Spherical Rubber JointKXT Rubber Soft JointFlange Adaptor

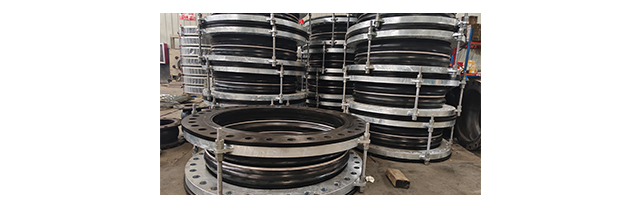

Why Are Rubber Joints Essential in Modern Pipeline Systems?

In every pipeline system, flexibility and safety are critical factors. Pipelines often face challenges such as thermal expansion, vibration, noise, and misalignment. Without proper protection, these issues can cause leakage, equipment damage, and costly downtime.

This is where the rubber joint, also known as a rubber expansion joint or flexible rubber connector, becomes an indispensable solution.

In this article, we will explain:

✔✔ What is a rubber joint?

✔✔ Where are rubber joints used?

✔✔ What are the key features and advantages?

✔✔ How should rubber joints be installed and maintained?

By the end, you’ll understand why rubber joints are essential for water, HVAC, wastewater, and industrial projects — and why choosing the right manufacturer like WEIZIDOM matters.

What is a Rubber Joint?

A rubber joint is a flexible connector made of natural or synthetic rubber, often reinforced with fabric and steel. It is designed to absorb:

✅ Vibration

✅ Noise

✅ Thermal expansion and contraction

✅ Pipe misalignment

Rubber joints are widely used in water supply systems, chemical plants, HVAC, wastewater treatment, and industrial pipelines.

Basic Structure of Rubber Joints

✅ Rubber body – The main flexible part, made from materials like EPDM, NBR, or natural rubber.

✅ Fabric reinforcement – Provides strength and durability.

✅ Steel flanges – Used to connect the joint to the pipeline.

✅ Optional inner liner – For aggressive chemicals or high-temperature applications.

Applications of Rubber Joints

Rubber joints are versatile and can be found in many industries:

✅ Water Supply and Plumbing Systems

Absorb vibration in pumps and pipelines

Protect water meters and valves from shock

Prevent leakage caused by misalignment

✅ HVAC and Air Conditioning

Reduce noise and vibration in chillers and pumps

Compensate for temperature changes in hot and cold water systems

✅ Wastewater Treatment

Withstand corrosive environments

Handle solid-containing fluids

Improve pipeline flexibility in treatment plants

✅ Industrial and Chemical Plants

Resistant to acids, alkalis, and solvents (with NBR or EPDM rubber)

Reduce stress on connected equipment

Allow safe expansion in high-pressure systems

✅ Power Plants and Oil & Gas

Compensate for pipeline movement due to high temperature and pressure

Provide protection for turbines, compressors, and boilers

Features and Advantages of Rubber Joints

✅ Excellent Flexibility

Rubber joints allow axial, lateral, and angular movements, making them ideal for pipelines subject to movement and vibration.

✅ Vibration and Noise Reduction

They act as a shock absorber, protecting pumps, valves, and meters from vibration and reducing operational noise.

✅ Corrosion Resistance

Made with materials such as EPDM, NBR, or Neoprene, rubber joints resist various fluids and harsh conditions.

✅ Easy Installation and Maintenance

Their compact and lightweight design makes rubber joints easy to install, especially in narrow pipeline spaces.

✅ Cost-Effective

Compared to metal expansion joints, rubber joints are more economical while still offering long service life.

✅ Long Service Life

When properly selected and maintained, rubber joints can last many years, even in demanding applications.

Installation Guidelines for Rubber Joints

Correct installation is key to ensuring the performance and durability of rubber joints.

✔✔ Step 1: Preparation

Inspect the rubber joint before installation

Clean flanges and pipeline ends to remove debris

✔✔ Step 2: Alignment

Ensure that the pipeline is aligned before installing the joint

Avoid twisting or stretching the rubber body during installation

✔✔ Step 3: Bolting

Tighten flange bolts evenly in a cross pattern

Do not overtighten, as it may damage the rubber body

✔✔ Step 4: Support

Use proper supports and anchors in the pipeline

Do not allow the rubber joint to bear the weight of the pipeline

✔✔ Step 5: Pressure Testing

After installation, conduct a hydrostatic test to ensure there are no leaks

Maintenance of Rubber Joints

To extend the service life of rubber joints, regular maintenance is necessary:

✅ Periodic Inspection

Check for cracks, leaks, or deformation of the rubber body.

✅ Bolt Tightness

Inspect flange bolts regularly and tighten if necessary.

✅ Environmental Protection

Avoid direct sunlight, ozone exposure, or chemical splashes that may damage the rubber.

✅ Replacement Cycle

Replace the rubber joint when significant wear or leakage is observed, typically every 5–10 years depending on service conditions.

Common Problems and Solutions

✔✔ Problem 1: Leakage at Flanges

Cause: Improper tightening of bolts or gasket failure

Solution: Retighten bolts evenly or replace gaskets

✔✔ Problem 2: Excessive Expansion or Deformation

Cause: Overstretching due to incorrect installation

Solution: Ensure proper pipeline alignment and supports

✔✔ Problem 3: Rubber Cracking

Cause: Exposure to UV, ozone, or aggressive chemicals

Solution: Use UV-resistant rubber or protective covers

Why Choose WEIZIDOM Rubber Joints?

At WEIZIDOM, we are dedicated to providing high-quality rubber expansion joints for global customers.

✔ Factories across China – specialized in ductile iron valves, stainless steel valves, flow meters, and rubber joints

✔ 100+ export countries and 1000+ project references

✔ Customized solutions for water, wastewater, HVAC, chemical, and industrial applications

✔ Competitive pricing directly from the manufacturer

With years of experience in the valve and pipeline industry, we ensure every product meets international standards and customer expectations.

Conclusion: Rubber Joints – Small Part, Big Role

The rubber joint may be a small component in a pipeline system, but its impact is huge. From reducing vibration and noise to compensating for expansion and protecting equipment, it ensures smooth and safe operation.

By choosing high-quality rubber joints from a trusted manufacturer like WEIZIDOM, you can:

✔Reduce maintenance costs

✔Improve system reliability

✔Extend equipment life

✔✔ Contact us at eileen@wsdsolution.com for technical support, free catalogs, and quotations.

✔✔ Visit: www.wsdsolution.com

Frequently Asked Questions (FAQ) About Rubber Joints

✅ What is the purpose of a rubber joint in pipelines?

A rubber joint is designed to absorb vibration, reduce noise, compensate for thermal expansion, and allow flexibility in pipelines. It also helps to protect pumps, valves, and meters from damage caused by misalignment or excessive stress.

✅ What materials are rubber joints made of?

Rubber joints are typically made of:

EPDM (Ethylene Propylene Diene Monomer) – Excellent resistance to water, steam, and chemicals

NBR (Nitrile Rubber) – Good for oil, gas, and hydrocarbon applications

Natural Rubber – Cost-effective, ideal for water pipelines

Neoprene – Resistant to weathering and abrasion

Reinforced with fabric and steel, these materials ensure durability and flexibility.

✅ Where are rubber joints commonly used?

Rubber joints are widely applied in:

Water supply and plumbing systems

Wastewater treatment plants

HVAC (Heating, Ventilation, Air Conditioning)

Chemical and industrial pipelines

Power plants and oil & gas facilities

✅ How long does a rubber joint last?

The service life of a rubber joint depends on the working environment, media, pressure, and maintenance. Generally, high-quality rubber joints can last 5–10 years or longer if properly installed and maintained.

✅ How do you install a rubber joint correctly?

Clean flange surfaces before installation

Ensure proper alignment of the pipeline

Tighten bolts evenly in a cross pattern

Avoid overtightening to prevent damage

Do not let the joint carry the weight of the pipeline — always use proper supports

✅ How do you maintain a rubber joint?

Perform regular inspections for cracks, deformation, or leaks

Check flange bolts and retighten if necessary

Protect the joint from UV light, ozone, and aggressive chemicals

Replace when signs of significant wear appear to prevent pipeline failure