- Gate valve

-

- DN1000 Extension stem double flange soft seal gate valveDIN F4 resilient seated gate valveDN450-1200 Resilient Seated Gate ValveDIN F5 resilient seated gate valveSocket connection soft seal gate valveUnderground cap soft seal gate valveBS5163 rising stem soft seal gate valveHard seal gate valveAPI slab Gate ValveStainless steel flange gate valveWafer knife gate valvePneumatic gate valveSoft seal gate valveExtension stem gate valveUL/FM fire protection groove ends gate valveRising stem forged steel gate valvecarbon steel gate valveStainless steel threaded gate valveDIN soft seal gate valveANSI soft sealing gate valve 200PSICast iron gate valveBS resilient seated gate valve

- Butterfly valve

-

- DN900 pneumatic triple eccentric hard seal butterfly valveD643H Triple Eccentric Butterfly ValveD343H Hard seal butterfly valveMulti standard EPDM seated butterfly valveSingle flange butterfly valveDN2000 Double eccentric butterfly valveFlange butterfly valveLug butterfly valveWafer butterfly valve with handleWorm gear operated butterfly valveWafer lined fluorine butterfly valveStainless steel wafer butterfly valveStainless steel flanged butterfly valveThree eccentric flange butterfly valvePneumatic flanged butterfly valvePneumatic wafer butterfly valveTriple eccentric butterfly valve wafer typeWafer butterfly valve ULC approvedInflatable seat butterfly valveHigh performance butterfly valveGrooved end butterfly valveElectric soft seal butterfly valveFlange fluorine lined butterfly valveHandle aluminum butterfly valveWorm Gear Aluminum Butterfly ValveFull PTFE lined butterfly valve wafer typeOne stem no-pin wafer butterfly valveMulti standard aluminum stem butterfly valveStainless Steel wafer Butterfly ValveAluminium handle operated lug butterfly valveLever Operated Flange Butterfly ValveButterfly valve stemButterfly valve discButterfly valve seat

- Ball valve

-

- DN1400 top-mounted eccentric semi-ball valveFlanged three-way ball valveFully welded ball valveNatural gas ball valveHigh platform flange ball valve1 PC ball valveFixed ball valvePTFE seat flanged ball valveMetal seat ball valveAPI 6D ball valve3 Piece ball valveFull Bore 3 way ball valve L-Port3 Way T-Port ball valve2PC Ball valve female thread stainless steel

- Globe Valve

-

- API Carbon Steel Globe ValveBellows Globe ValveStainless steel flange globe valveStainless steel thread S type globe valveStainless steel thread B type globe valveCast Steel Globe ValvePiston Globe ValveWCB Carbon Steel Globe Check Valveelectric motorized control stainless steel SS316 globe valveBrass Globe ValveCryogenic Globe valveHT200 Globe ValveThreaded Stainless Steel Globe ValveGG25 Globe ValveANSI API Cast Steel And Stainless Steel Globe valve

- Check valve

-

- Rubber seal check valveDN800 Slow closing check valveDN800 Rubber Disc Check ValveButterfly Buffering Check Valvecheck valve with counter weightSilent Check ValveWCB Swing check valveSwing Check ValveSingle Chip Check Valve H74WStainless Steel Wafer Check ValveSwing Start Check ValveFoot check valveAPI Swing Check ValveDIN Flange check valveSingle plate check valveLifting Check ValveBottom ValveHammer Diminish Noises Check ValveWafer Check ValveWafer dual plate check valve

- Control valve

-

- Static Balancing ValveCage Guided Sleeve Globe Control ValveDN1000 Piston Flow Regulating ValveDN1600 Electric Actuator Flow Regulating ValvePneumatic Flanged Butterfly ValvePneumatic Wafer Butterfly ValveAngle Seat ValvePneumatic gate valveElectric three-way control valveElectric sleeve control valve

- Water Meter

-

- Vertical Type Water MetersStainless steel threaded water meterPiston water meterPlastic water meterMore flow rotor dry water meterspiral vane flange water meterCI wotlman water meter with pulse outputLXCLG(R) Vertical removable element woltman cold (hot) water meterSingle flow rotor dry water meterPrepaid Token Water MeterElectromagnetic flowmeterRotary Piston Liquid Sealed Water MeterRotary Piston Liquid Sealed Water Meter

- Air valve

-

- Double ball exhaust valveDoubleair Air Valve SaudiDoubleair Air Valve Southeast AsiaDoubleair Air Valve South AmericaDouble Air ValveThreaded Air ValveSingle Air ValveTriple Functions Air ValveAutomatic Air Release ValveAutomatic release valveAutomatic exhaust valveComposite Exhaust Air ValveBrass exhaust valveDouble Ball Air Valve

- Pipe Repair & Coupling

-

- Flexible Multi-Function Pipe Coupling ZFJ-SSS Semi-Circle Pipe Repair Clamp SJW-HDuctile Iron Band Repair ClampStainless Steel Band Repair ClampDouble-Section Pipe Repair CouplingFolding Type Pipe RepairSingle-Section Multi-Function Pipe Coupling MF-SGear-Ring Type Multi-Function Pipe Coupling GR-SZBW Damping Corrugated Hose

- Dismantling Joint

-

- VSSJAFC(CC2F) Detachable Flange Transmission JointVSSJA-2(B2F) Double Flange Limited Expansion JointVSSJA-1(BF) Single Flange Limited Expansion JointVSSJA(AF) Flange Loose Expansion JointJGD-B Threaded Rubber JointZBW Damping Corrugated HoseKXT-S Flexible Dual-Spherical Rubber JointKXT Rubber Soft JointFlange Adaptor

Electromagnetic flowmeter common faults and solutions

Electromagnetic flowmeter is a professional industrial instrument, which is widely used in the production industry, with good reliability and stability. This paper starts from the principle of the electromagnetic flowmeter, focuses on describing the electromagnetic flowmeter in the commissioning, and operation during the common five kinds of fault phenomena, and detailed analysis of the reasons for these failures and solutions. Skilled in solving these faults skills, can shorten the electromagnetic flowmeter troubleshooting time, better for the production service.

Electromagnetic flowmeter working principle:

Electromagnetic flowmeter is suitable for measuring the volume flow of electrically conductive liquids and slurries in closed pipelines, and it is based on the working principle of Faraday's law of electromagnetic induction: when a conductor in a magnetic field in motion, in the direction of the magnetic field, the direction of motion mutually perpendicular to the direction of the ends of the conductor, there will be an induced electromotive force; the magnitude of the electromotive force with the speed of movement of the conductor and the size of the magnetic field of the magnetic field of induction is directly proportional to the size of the magnetic field of induction. Electromagnetic flowmeter by the transmitter and converter two parts.

The transmitter (also known as the sensor) is based on Faraday's law of electromagnetic induction work.

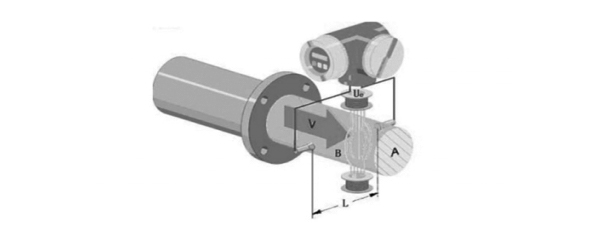

The principle is shown in the figure below:

The measuring tube is equipped with magnetizing coils, the two electromagnetic coils at the upper and lower ends produce a constant magnetic field after passing the magnetizing current; the measured medium (i.e., the conductive medium inside the measuring tube) flows perpendicular to the direction of the magnetic lines of force, then the induced potential Ex will be generated; a pair of electrodes mounted on the inner wall of the measuring tube in contact with the liquid, induced voltage is induced, and sent to the converter. In recent years, with the depth of the theoretical technology, wesdom in the design and manufacture, in the measurement of electrodes within the plane of the two ground electrodes, so that no need to add, grounding ring can be eliminated to eliminate electrical noise interference.

The converter is a high input impedance, and can suppress various interference components of the AC millivolt converter. Generally available in one-piece type (signal converter mounted directly on the measurement sensor) and split type (electrical connection to the measurement sensor through the excitation cable and signal cable).

On the one hand, the converter supplies a stable excitation current to the excitation coil of the sensor to ensure that B is a constant. On the other hand, when B is stable, the sensor inductance of electric potential amplification, converted into a standard current signal or frequency signal, easy to flow display, control and regulation.

Troubleshooting in the use of electromagnetic flowmeter:

The elimination method is to analyze the fault to find the possible causes, and then one by one elimination;

The replacement method is unable to determine whether a component or part is faulty, replace a good to judge.

Electromagnetic flowmeter in operation to produce two kinds of faults:

First, the instrument itself, that is, the instrument structure or component damage caused by the failure;

The second is caused by external causes of failure, such as improper installation flow distortion, deposition and scaling.

The following two types of failure on the cause of analysis and solutions:

1, No flow signal output instrument

This type of failure is more common in the early stage of installation and use, common causes and countermeasures are as follows:

(1) Check whether the instrument is powered:

Need to confirm access to the power supply is normal; second check to confirm the flow meter power circuit board output voltage to be normal, if encountered difficult to judge the situation, replace the entire power circuit board; but also check whether the power fuse is intact;

(2) Check whether the cable connection is connected correctly:

To check whether the cable is intact, the line connection is correct.

(3) Check whether the liquid flow direction is consistent with the setting:

For the electromagnetic flowmeter can be measured in the forward and reverse directions, if the direction is not the same, the total amount of the reverse direction can be accumulated, but the converter output may be "0" (4mA or 0mA), you must set the settings of the "reverse measurement is allowed" state set to "allow". Allowed" in the settings must be set to "Allowed."

(4) Sensor parts are damaged or there is an adherent layer on the inside wall of the measurement:

Check whether the electrode on the inner wall of the transmitter is covered with liquid scars, and clean up the measurement liquid which is easy to be scarred regularly.

(5) Check whether the liquid in the pipe is full or there is no "empty pipe alarm":

The pipeline is not full of liquid is mainly caused by the sensor installation location is not appropriate, should be installed to take measures to avoid causing the liquid in the pipe is not full of pipe. If the empty pipe alarm, to check whether the converter components are damaged, can be shorted converter input signal to see whether the alarm disappears, if it disappears, the converter is normal; if the judgment is that the converter components are damaged caused by the failure, replace the damaged components can be.

2, The output value fluctuations

In order to ensure the accuracy of the measurement, such failures should not be ignored

(1) Caused by the measurement medium or the influence of the external environment:

At this time to check the fluid process, to confirm that the process operation reasons for fluid pulsation do occur, or the pipeline is not full of liquid or liquid containing air bubbles and so on. At this time, the flow meter only faithfully reflect the flow conditions, when the end of the pulsation or the liquid filled with pipeline faults can be eliminated on their own;

(2) Due to strong electromagnetic interference:

In this case, we should check whether the instrument operating environment of large electrical appliances or welding machine at work, to confirm that the instrument grounding and operating environment is good, to avoid electromagnetic interference.

(3) Loose circuit board:

Transmitter circuit board for the plug-in structure, in some production environments, due to the measurement of pipeline or liquid vibration, will cause the flow meter circuit board loose, can also cause fluctuations in the output value. If loose, the flowmeter can be disassembled, re-fixed circuit board.

3, The measured value of the flow rate does not match the actual value:

(1) Check whether the transmitter circuit board is intact, if the junction box into the water or corrosive measured liquid corrosion, can lead to electrical performance decline or damage. At this time, the circuit board should be replaced.

(2) Check whether the flow rate is above the specified minimum flow rate:

When the liquid flow rate is too low, the measured liquid contains tiny bubbles, bubbles rise in the pipeline above the gradual aggregation of the liquid circulation area changes, the gas more will also produce interference signals, affecting the accuracy of the measurement; to ensure that the pipeline flow rate of the measured liquid in the minimum flow rate above the threshold value, in order to enable the transmitter to work properly.

(3) Check the signal cable connection and cable insulation is intact:

Signal cable connection is bad phenomenon or the use of the insulation of the cable in the process of degradation caused by inaccurate measurements; at this time, if the signal cable loosening phenomenon, will be reconnected to; if you check to the insulation of the cable does not meet the insulation requirements, it is necessary to change the new cable.

(4) Check whether the parameter setting value of the converter is accurate:

At this time to re-set the converter set value, and the zero point of the converter, the fullness value of the calibration.

4, The output signal exceeds the fullness range:

(1) Check the signal to check the signal circuit connection is normal or not if the signal circuit is disconnected, the output signal will exceed the fullness value, this time you need to check the cable, reconnect the signal cable correctly. At the same time, need to check whether the insulation of the cable is intact, if it is not in line with the requirements, it is necessary to replace the new cable.

(2) Check whether the parameter setting of the converter is correct.

Check in detail whether the parameter settings of the converter and the zero point and fullness meet the requirements.

(3) Check whether the converter and the sensor model matching.

If the model does not match, it is necessary to contact with the factory replacement.

5, Zero point instability:

(1) Check whether the pipeline is not full of liquid or liquid containing air bubbles

Pipes are not full of liquid or liquid containing air bubbles are process reasons, this time should ask the process staff to confirm that the process is normal, the output value can return to normal.

(2) Check whether there is a trace of flow in the pipe

Sometimes, subjectively think that the pump liquid flow but in fact there is a small flow, this is a truthful reflection of the working conditions, not electromagnetic flowmeter failure.

(3) Check whether the electrode pollution

If long-term operation, the impurities in the liquid deposition of the measuring tube wall or in the measuring tube wall scaling, or electrode contamination, there may be zero change, this time must be cleaned; if the zero change is not large, you can also try to re-zero.

(4) Signal circuit insulation degradation

Due to the impact of environmental conditions, dust, oil and so on may enter the case body, therefore, need to check whether the electrode part of the insulation decline or damage, if not in line with the insulation requirements, it must be cleaned.

The summary:

Electromagnetic flowmeter generally does not require frequent maintenance. When there are failures, proficiency in troubleshooting skills, combined with its measurement principle, can shorten the electromagnetic flowmeter troubleshooting time, better service for production.

Each of our products has undergone strict inspection and testing before reaching your hands.

We look forward to working with you!

To learn more about our products, please contact:

WhatsApp: +86 13849184495

Email: weisidun888@gmail.com