- Gate valve

-

- DN1000 Extension stem double flange soft seal gate valveDIN F4 resilient seated gate valveDN450-1200 Resilient Seated Gate ValveDIN F5 resilient seated gate valveSocket connection soft seal gate valveUnderground cap soft seal gate valveBS5163 rising stem soft seal gate valveHard seal gate valveAPI slab Gate ValveStainless steel flange gate valveWafer knife gate valvePneumatic gate valveSoft seal gate valveExtension stem gate valveUL/FM fire protection groove ends gate valveRising stem forged steel gate valvecarbon steel gate valveStainless steel threaded gate valveDIN soft seal gate valveANSI soft sealing gate valve 200PSICast iron gate valveBS resilient seated gate valve

- Butterfly valve

-

- DN900 pneumatic triple eccentric hard seal butterfly valveD643H Triple Eccentric Butterfly ValveD343H Hard seal butterfly valveMulti standard EPDM seated butterfly valveSingle flange butterfly valveDN2000 Double eccentric butterfly valveFlange butterfly valveLug butterfly valveWafer butterfly valve with handleWorm gear operated butterfly valveWafer lined fluorine butterfly valveStainless steel wafer butterfly valveStainless steel flanged butterfly valveThree eccentric flange butterfly valvePneumatic flanged butterfly valvePneumatic wafer butterfly valveTriple eccentric butterfly valve wafer typeWafer butterfly valve ULC approvedInflatable seat butterfly valveHigh performance butterfly valveGrooved end butterfly valveElectric soft seal butterfly valveFlange fluorine lined butterfly valveHandle aluminum butterfly valveWorm Gear Aluminum Butterfly ValveFull PTFE lined butterfly valve wafer typeOne stem no-pin wafer butterfly valveMulti standard aluminum stem butterfly valveStainless Steel wafer Butterfly ValveAluminium handle operated lug butterfly valveLever Operated Flange Butterfly ValveButterfly valve stemButterfly valve discButterfly valve seat

- Ball valve

-

- DN1400 top-mounted eccentric semi-ball valveFlanged three-way ball valveFully welded ball valveNatural gas ball valveHigh platform flange ball valve1 PC ball valveFixed ball valvePTFE seat flanged ball valveMetal seat ball valveAPI 6D ball valve3 Piece ball valveFull Bore 3 way ball valve L-Port3 Way T-Port ball valve2PC Ball valve female thread stainless steel

- Globe Valve

-

- API Carbon Steel Globe ValveBellows Globe ValveStainless steel flange globe valveStainless steel thread S type globe valveStainless steel thread B type globe valveCast Steel Globe ValvePiston Globe ValveWCB Carbon Steel Globe Check Valveelectric motorized control stainless steel SS316 globe valveBrass Globe ValveCryogenic Globe valveHT200 Globe ValveThreaded Stainless Steel Globe ValveGG25 Globe ValveANSI API Cast Steel And Stainless Steel Globe valve

- Check valve

-

- Rubber seal check valveDN800 Slow closing check valveDN800 Rubber Disc Check ValveButterfly Buffering Check Valvecheck valve with counter weightSilent Check ValveWCB Swing check valveSwing Check ValveSingle Chip Check Valve H74WStainless Steel Wafer Check ValveSwing Start Check ValveFoot check valveAPI Swing Check ValveDIN Flange check valveSingle plate check valveLifting Check ValveBottom ValveHammer Diminish Noises Check ValveWafer Check ValveWafer dual plate check valve

- Control valve

-

- Static Balancing ValveCage Guided Sleeve Globe Control ValveDN1000 Piston Flow Regulating ValveDN1600 Electric Actuator Flow Regulating ValvePneumatic Flanged Butterfly ValvePneumatic Wafer Butterfly ValveAngle Seat ValvePneumatic gate valveElectric three-way control valveElectric sleeve control valve

- Water Meter

-

- Vertical Type Water MetersStainless steel threaded water meterPiston water meterPlastic water meterMore flow rotor dry water meterspiral vane flange water meterCI wotlman water meter with pulse outputLXCLG(R) Vertical removable element woltman cold (hot) water meterSingle flow rotor dry water meterPrepaid Token Water MeterElectromagnetic flowmeterRotary Piston Liquid Sealed Water MeterRotary Piston Liquid Sealed Water Meter

- Air valve

-

- Double ball exhaust valveDoubleair Air Valve SaudiDoubleair Air Valve Southeast AsiaDoubleair Air Valve South AmericaDouble Air ValveThreaded Air ValveSingle Air ValveTriple Functions Air ValveAutomatic Air Release ValveAutomatic release valveAutomatic exhaust valveComposite Exhaust Air ValveBrass exhaust valveDouble Ball Air Valve

- Pipe Repair & Coupling

-

- Flexible Multi-Function Pipe Coupling ZFJ-SSS Semi-Circle Pipe Repair Clamp SJW-HDuctile Iron Band Repair ClampStainless Steel Band Repair ClampDouble-Section Pipe Repair CouplingFolding Type Pipe RepairSingle-Section Multi-Function Pipe Coupling MF-SGear-Ring Type Multi-Function Pipe Coupling GR-SZBW Damping Corrugated Hose

- Dismantling Joint

-

- VSSJAFC(CC2F) Detachable Flange Transmission JointVSSJA-2(B2F) Double Flange Limited Expansion JointVSSJA-1(BF) Single Flange Limited Expansion JointVSSJA(AF) Flange Loose Expansion JointJGD-B Threaded Rubber JointZBW Damping Corrugated HoseKXT-S Flexible Dual-Spherical Rubber JointKXT Rubber Soft JointFlange Adaptor

How to choose the right flow meter?

WSDWG series gas turbine flow meter is one kind of precision measuring instruments which for gas measuring. This flow meter has the characteristics of low pressure loss, high accuracy, low initiating flow, anti vibration and pulsation flow resistance, widely range ratio etc.

When design WSDWG series gas turbine flow meter, we consider the gas compressibility, Volume quantity is closely related with medium temperature and pressure, thus we add the temperature and pressure sensors so that monitor the change of medium temperature and pressure, directly make working condition flow change into standard condition flow and ensure measuring accuracy.

WSDWG series gas turbine flow meter could be separately used for gas that is clean, low viscosity, such as Air, Natural gas, LPG, Methane gas, N2, Ar, Co₂, CO etc.

WSDWG could be widely used in gas measuring from Petroleum, Chemical, Electric power, Industrial boiler etc. In addition, WSDWG series gas turbine flow meter also be used in Gas-fired, Gas pipeline network, city gas field etc.

Working Principle of gas turbine flow meter:

WSDWG gas turbine flow meter is made up of base table and display, among them, the base table contains body, Rectifier, Turbo, Temperature sensor, Magnetic switch sensor, Pressure sensor and other important parts.

When medium enter the flow meter, through integration of the two level rectifier, medium be rectified and accelerated, then acts on the turbine blades which make a certain angle with flow direction, same time turbine will produces rotational torque, turbine blades begins to rotate after turbine overcomes the resistance moment and friction moment. When all moments reach balance, invariables turning speed, turbine rotation angular velocity is liner relationship with flow. Utilizing electromagnetic induction principle, through the top magnetizer of rotating turbine generator periodically change magnetic resistance and make magnetic field change accordingly, thus induction of the pulse signal that it is proportional to the volume flow rate.

This signal is amplified by preamplifier and shaped, the signal will be entered into integrating instrument together the temperature and pressure signal, then the integrating instrument will calculate and convert to flow value, the directly display standard instantaneous volume flow and total flow.

Features of gas turbine flow meter:

* Rectifying device could be installed at the installation conditions not good and medium velocity change larger, also could keep there liability of measurement.

* Adopt RS485 communication, could be matched with MODEM, through telephone network could build automatic reading management system, higher automation.

* Dust-proof structure can effectively prevent the impurity of the medium enter into bearing and cause rapid wear and stuck.

* Adopt E2-PROM data storage technology,setup parameters could be keep long time after outage.

* Low installation requirements,front straight pipe≥2D, back straig ht pipe≥1D,this could ensure the accuracy of flow meter.

* The low voltage alarm(≤2.7V)of internal battery could remind user to replace battery.

* Intelligent integration design could dynamically detect the temperature and pressure of medium, and automatic compensation and compression factor correction,directly display gas standard instantaneous flow and standard total flow.

* The intelligent integrating instrument could rotate 180 degrees, it is convenient reading, Unexpected power outage, Autosave data, Prevent data lost.

* Aluminum alloy turbine have some features: High strength, Corrosion resistance, Anti-aging, Long service life, High accuracy and good repeatability.

* Flow meter with signal output calibration function and could 4,8,16,20mA and 0~1000Hz.

* Advanced microcomputer technology and high performance singe chip make complete meter more powerful and superior performance.

* Adopt over wide temperature LCD technology,and LCD display converter can bear max. 80℃.

* Advanced double power supply and micro power consumption technology, complete meter with low power consumption. Both could run on battery for a long time (Two lithium batteries could be used 3 years) and also could connect outside power.

* Outside power is isolated with main circuit of flow meter, Isolation voltage reach 1000V.

* Large screen backlight LCD display,could clearly reading under dark environment.

* Reliable electromagnetic compatibility design.

* Flow meter with pulse output, also could add 4-20mA output, IC card quantitative pulse signal etc. According to user's requirement.

* One aviation plug, all output terminal.

Liquid Turbine Flow Meter

Liquid flows through the turbine housing causing an internal rotor to spin. As the rotor spins, an electrical signal is generated in the pickup coil. This signal is converted into engineering units ( liters, cubic meters, gallons etc. ) on the local display where is applicable. Optional accessory modules can be used to export the signal to other equipment.

Upon receipt, examine your meter for visible damage. The turbine is a precision measuring instrument and should be handled carefully.

Remove the protective plugs and caps for a thorough inspection. If any items are damaged or missing, contact.

Make sure the turbine flow model meets your specific needs. For your future reference, it might be useful to record this information on nameplate in the manual in case it becomes unreadable on the turbine. Refer to the nameplate for your customized product's specification.

Warning

For your safety, review the major warnings and cautions below before operating your equipment.

* Use only fluids that are compatible with the housing material and wetted components of your turbine.

* When measuring flammable liquids, observe precautions against fire or explosion.

* When handling hazardous liquids, always follow the liquid manufacturer's safety precautions.

* When working in hazardous environments, always exercise appropriate safety precautions.

* During turbine removal, liquid may spill. Follow the liquid manufacturer's safety precautions for clean up of minor spills.

* Do not blow compressed air through the turbine.

* Handle the rotor carefully. Even small scratches or nicks can affect accuracy.

* When tightening the turbine, use a wrench only on the wrench flats.

* For best results,calibrate the meter at least 1 time per year.

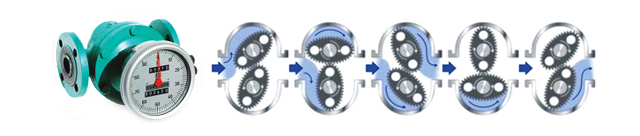

Oval Gear Flow Meter

Oval gear flow meter is one of positive displacement flow meter and mainly composed of meter shell, oval gear rotor and converter. It is an instrument used for continuous or discontinuous metering and control of liquids in the pipeline. It has advantages of large metering range, excellent accuracy, small pressure loss and high viscosity adaptability etc; It has good performance on measuring high-temperature and high-viscosity liquids. It is applicable to the calibration and metering of crude oil, chemical,chemical fiber, traffic, commerce, food, medicine and health, scientific research and military etc.

Working Principle and Structure:

Flow meter is installed in the metering tank and the measurement of a pair of oval box gear, with the upper and lower cover, an early Lunar sealed cavity (due to rotation of the gear, so sealing is not an absolute) as a unit of emissions. When measured by the pipe into the liquid flow meter, due to pressure generated by the Import and Export Department to promote a pair of differential gears for rotation, the constant measurement by cavity after the beginning of the Lunar liquid delivery to the exit, elliptical gear with each revolution time displacement is the product of four times the measured volume of liquid flow.

Flow meter is made by the shell, counter, oval gear and coupling (magnetic coupling and sub-axial coupling) and so on.

Coriolis Mass Flow Meter

Working principle:

Advantages and features:

Can output mass flow, density, temperature, etc. at the same time

High accuracy, suitable for a variety of complex media

Can measure non-Newtonian fluids and multiphase flows

Applicable working conditions:

✔ High-end applications: chemical, pharmaceutical, natural gas, liquefied gas

✔ Especially suitable for high-quality measurement occasions

✘ Expensive, suitable for projects with sufficient budget

Thermal Mass Flow Meter

Working Principle

Thermal mass flow meters operate based on the principle of heat transfer. Typically, two temperature sensors and a heating element are placed within the gas stream. As the gas flows past the heated sensor, it absorbs heat and carries it away. The rate of heat loss is directly proportional to the mass flow rate of the gas.

Key Advantages

Direct Mass Flow Measurement

No need for additional sensors or compensation — get accurate mass flow data instantly.

Highly Accurate for Gases

Especially effective for low and medium velocity gas flow applications.

No Moving Parts

Reduces wear and tear, lowers maintenance needs, and ensures long service life.

Wide Turn down Ratio

Typically offers a range of 100:1 or more, allowing accurate readings from very low to high flow rates.

Minimal Pressure Drop

The non-intrusive sensor design ensures the pressure loss in the pipeline is negligible.

Easy Installation and Integration

Available in inline or insertion types, suitable for various pipe diameters and systems.

Common Application Scenarios

Thermal mass flow meters are best suited for clean, dry, single-phase gases. They are widely used in:

Compressed Air Systems

Accurate monitoring of air consumption and leakage detection.

Natural Gas Measurement

Fuel gas flow measurement in industrial furnaces, boilers, and heating systems.

Biogas and Flue Gas Monitoring

Used in waste-to-energy plants and emission monitoring systems.

Gas Distribution Networks

Efficient flow management in process and utility gas pipelines.

Semiconductor and Electronics Industries

Precise control of specialty gases in manufacturing processes.

HVAC and Building Management Systems

For measuring airflow in ventilation and duct systems.

Metal Tube Rotameter

WSDLZZ Series intelligent metal tube rotameter is a variable area flow meter which is based on the float position measurement. With full-metal structure, it has the features of small size, low pressure loss, large range ratio(10~20:1), optional transmitter with HART communication function, and convenient installation & maintenance etc. It is widely used in flow measurement and process control of small flow, low flow rate, and various industries under complex and harsh environments.

Working Principle

The flow meter consists of a measuring tube and a float inside it. The flow pushes the float to an equilibrium point. The area obtained between the float and the tube is proportional to the flow rate.

The point of equilibrium depends on:

E=Force of the fluid flow

Ff=Weight of the float

Al=Free area of flow

Where:

Al=Ao (calibrated orifice area)- Af (float area)

Features

* Robust all-metal structure design.

* Suitable for gas and liquid measurement in various industries.

* Cone-shape measuring tube design, which has wide measuring range and good linearity.

* Wetted parts material are optional: SS304 SS316L, FEP, Hastelloy C, Titanium.

* Adopt advanced magnetic coupling system design, improve the accuracy and stability.

* The upper row displays the instantaneous flow, the lower row displays the total flow.

* For the digital LCD display type, the flow range of the instantaneous flow can be corrected onsite based on the different measuring medium.

* It adopts advanced six level data back up technology, data of total flow can be saved

automatically when power-off, (the total flow sending period is 0.3S).

* Besides AC/DC power supply, it supports battery power supply function.

* No need to open the cover, it can be operated by a magnetic pen; the key operation function is also available.

* Through the HART protocol, you can use the handheld operator or host computer software to perform partial or full configuration operations on the flow meter.

* Choosing the right flow meter means choosing efficiency and safety