- Gate valve

-

- DN1000 Extension stem double flange soft seal gate valveDIN F4 resilient seated gate valveDN450-1200 Resilient Seated Gate ValveDIN F5 resilient seated gate valveSocket connection soft seal gate valveUnderground cap soft seal gate valveBS5163 rising stem soft seal gate valveHard seal gate valveAPI slab Gate ValveStainless steel flange gate valveWafer knife gate valvePneumatic gate valveSoft seal gate valveExtension stem gate valveUL/FM fire protection groove ends gate valveRising stem forged steel gate valvecarbon steel gate valveStainless steel threaded gate valveDIN soft seal gate valveANSI soft sealing gate valve 200PSICast iron gate valveBS resilient seated gate valve

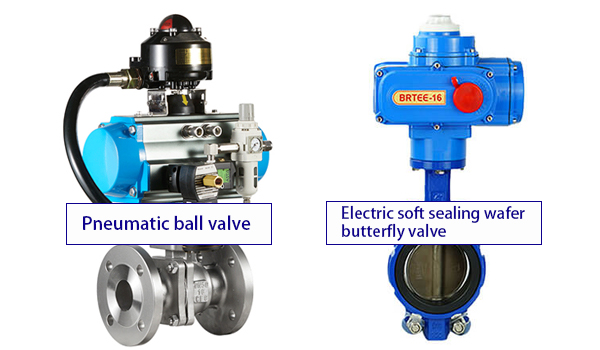

- Butterfly valve

-

- DN900 pneumatic triple eccentric hard seal butterfly valveD643H Triple Eccentric Butterfly ValveD343H Hard seal butterfly valveMulti standard EPDM seated butterfly valveSingle flange butterfly valveDN2000 Double eccentric butterfly valveFlange butterfly valveLug butterfly valveWafer butterfly valve with handleWorm gear operated butterfly valveWafer lined fluorine butterfly valveStainless steel wafer butterfly valveStainless steel flanged butterfly valveThree eccentric flange butterfly valvePneumatic flanged butterfly valvePneumatic wafer butterfly valveTriple eccentric butterfly valve wafer typeWafer butterfly valve ULC approvedInflatable seat butterfly valveHigh performance butterfly valveGrooved end butterfly valveElectric soft seal butterfly valveFlange fluorine lined butterfly valveHandle aluminum butterfly valveWorm Gear Aluminum Butterfly ValveFull PTFE lined butterfly valve wafer typeOne stem no-pin wafer butterfly valveMulti standard aluminum stem butterfly valveStainless Steel wafer Butterfly ValveAluminium handle operated lug butterfly valveLever Operated Flange Butterfly ValveButterfly valve stemButterfly valve discButterfly valve seat

- Ball valve

-

- DN1400 top-mounted eccentric semi-ball valveFlanged three-way ball valveFully welded ball valveNatural gas ball valveHigh platform flange ball valve1 PC ball valveFixed ball valvePTFE seat flanged ball valveMetal seat ball valveAPI 6D ball valve3 Piece ball valveFull Bore 3 way ball valve L-Port3 Way T-Port ball valve2PC Ball valve female thread stainless steel

- Globe Valve

-

- API Carbon Steel Globe ValveBellows Globe ValveStainless steel flange globe valveStainless steel thread S type globe valveStainless steel thread B type globe valveCast Steel Globe ValvePiston Globe ValveWCB Carbon Steel Globe Check Valveelectric motorized control stainless steel SS316 globe valveBrass Globe ValveCryogenic Globe valveHT200 Globe ValveThreaded Stainless Steel Globe ValveGG25 Globe ValveANSI API Cast Steel And Stainless Steel Globe valve

- Check valve

-

- Rubber seal check valveDN800 Slow closing check valveDN800 Rubber Disc Check ValveButterfly Buffering Check Valvecheck valve with counter weightSilent Check ValveWCB Swing check valveSwing Check ValveSingle Chip Check Valve H74WStainless Steel Wafer Check ValveSwing Start Check ValveFoot check valveAPI Swing Check ValveDIN Flange check valveSingle plate check valveLifting Check ValveBottom ValveHammer Diminish Noises Check ValveWafer Check ValveWafer dual plate check valve

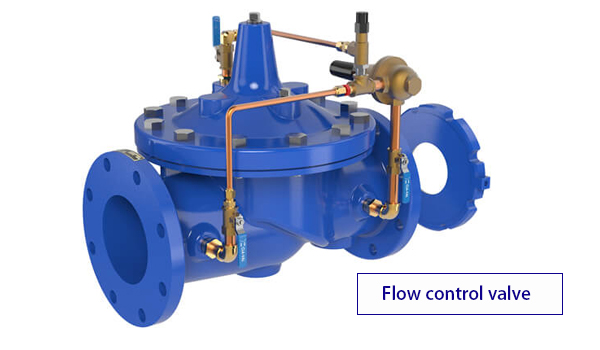

- Control valve

-

- Static Balancing ValveCage Guided Sleeve Globe Control ValveDN1000 Piston Flow Regulating ValveDN1600 Electric Actuator Flow Regulating ValvePneumatic Flanged Butterfly ValvePneumatic Wafer Butterfly ValveAngle Seat ValvePneumatic gate valveElectric three-way control valveElectric sleeve control valve

- Water Meter

-

- Vertical Type Water MetersStainless steel threaded water meterPiston water meterPlastic water meterMore flow rotor dry water meterspiral vane flange water meterCI wotlman water meter with pulse outputLXCLG(R) Vertical removable element woltman cold (hot) water meterSingle flow rotor dry water meterPrepaid Token Water MeterElectromagnetic flowmeterRotary Piston Liquid Sealed Water MeterRotary Piston Liquid Sealed Water Meter

- Air valve

-

- Double ball exhaust valveDoubleair Air Valve SaudiDoubleair Air Valve Southeast AsiaDoubleair Air Valve South AmericaDouble Air ValveThreaded Air ValveSingle Air ValveTriple Functions Air ValveAutomatic Air Release ValveAutomatic release valveAutomatic exhaust valveComposite Exhaust Air ValveBrass exhaust valveDouble Ball Air Valve

- Pipe Repair & Coupling

-

- Flexible Multi-Function Pipe Coupling ZFJ-SSS Semi-Circle Pipe Repair Clamp SJW-HDuctile Iron Band Repair ClampStainless Steel Band Repair ClampDouble-Section Pipe Repair CouplingFolding Type Pipe RepairSingle-Section Multi-Function Pipe Coupling MF-SGear-Ring Type Multi-Function Pipe Coupling GR-SZBW Damping Corrugated Hose

- Dismantling Joint

-

- VSSJAFC(CC2F) Detachable Flange Transmission JointVSSJA-2(B2F) Double Flange Limited Expansion JointVSSJA-1(BF) Single Flange Limited Expansion JointVSSJA(AF) Flange Loose Expansion JointJGD-B Threaded Rubber JointZBW Damping Corrugated HoseKXT-S Flexible Dual-Spherical Rubber JointKXT Rubber Soft JointFlange Adaptor

valve-electric,-pneumatic,-hydraulic,-electro-hydraulic-drive-mode-analysis-and-comparison

Traditional actuators are divided into three types: electric, pneumatic and hydraulic, and the derived gas-liquid combination and electro-hydraulic combined drive. Each type of drive has its own advantages and disadvantages. This article briefly explains the advantages and disadvantages of electric, pneumatic and hydraulic drives for everyone to quickly understand.

Electric actuators, as the name implies, are powered by electricity, using single-phase or three-phase motors to drive gears or worm gears to output linear or rotary motion. The electric actuator can output a relatively constant driving force, has strong anti-deviation ability, and has higher control accuracy than the pneumatic actuator, and can automatically maintain its position without the aid of other auxiliary systems. Electric actuators have the characteristics of simple operation and easy remote control. However, their structure is complex, and they are prone to failure due to load. There are often low positioning accuracy, over-opening and closing, motor burnout, gear box wear, etc., and the maintenance cost is high. Too frequent adjustment will cause the motor to heat up, and the reduction gear will be easily worn. In addition, the electric actuator runs slowly, it is difficult to achieve a large driving force, and there are problems such as difficulty in realizing over-protection and poor position.

2.Pneumatic actuator

The pneumatic actuator is powered by compressed air and has the characteristics of simple structure and convenient maintenance, but it is large in size and requires an air source and an air purification device; the actuator and adjustment mechanism of the pneumatic actuator are a unified whole, and its actuator has a thin film Type, piston type, fork type and rack and pinion type. Using gas as the power medium has the advantages of high safety and low requirements for the use environment. However, due to the compressibility of gas, pneumatic actuators with relatively low stiffness have slow response, poor resolution, low control accuracy, and weak anti-deviation ability. Undesirable vibration of the device. In addition, the power-to-weight ratio is poor, the power density is low, and the pneumatic actuator with a large driving force is extremely complex, heavy and expensive.

Ordinary hydraulic actuators are powered by high-pressure oil and have the characteristics of large load capacity and high adjustment accuracy, but they need to be equipped with huge independent oil supply equipment, and the maintenance workload is relatively large. Rack type, screw type actuator. All three have advantages and disadvantages. The vane type structure has a small bearing capacity and a lot of oil leakage; the rack and pinion type has a large bearing capacity, a simple structure, a large volume, accurate screw positioning, and high processing difficulty. The figure below shows the rack and pinion actuator mounted on the valve. Existing hydraulic actuators usually need to be matched with a hydraulic station, resulting in large volume, long hydraulic pipelines, large throttling losses, and inconvenient maintenance.

4.Electro-hydraulic actuator

As a power device derived from hydraulic actuators, electro-hydraulic actuators integrate hydraulic, control, electromechanical, computer, communication and other technologies, and can accurately control the position of the controlled object quickly and stably, and are used in various valves. Drive and control. The electro-hydraulic actuator integrates the hydraulic power module and the control module. The electro-hydraulic actuator integrates the simple electric operation, fast hydraulic power, and reliable electric control board, and has the advantages of fast response speed, high control precision, large output power, and compact structure; at the same time, the electro-hydraulic actuator overcomes the pneumatic actuator. The control accuracy is low, the controllability of the electric actuator is poor and so on. Electro-hydraulic actuators can be roughly divided into two types: one is the servo valve control type, that is, the traditional electro-hydraulic servo actuator, which adopts an open hydraulic system, and adjusts the flow direction and flow rate of hydraulic oil by controlling the servo valve, so as to realize the control of the hydraulic oil. The adjustment of the controlled object; one is the motor control type, which adopts a closed hydraulic system to control the output direction and flow of the pressure oil of the two-way pump by adjusting the steering and speed of the stepper motor or servo motor. Precise control of the controlled object.

The new electro-hydraulic actuator has the advantages of simple structure, compactness, small size, stable transmission, large output torque, convenient speed adjustment, easy control, and easy overload prevention. Features.

The hydraulic micro-power unit and control board are integrated in the control box, making the entire actuator intelligent and miniaturized. Electro-hydraulic actuator is an important control element of industrial automatic control system, which can adjust valve pressure, flow, temperature, etc., and is widely used in chemical, petroleum, metallurgy, electric power, coal and other industrial process control systems. The development of electro-hydraulic actuators is developing towards the trend of small size, light weight, high efficiency and energy saving, and high reliability.

The general principle for the correct selection of the valve drive device is: the operating characteristics of the drive device are required to be consistent with the operating characteristics of the valve. For valves that do not require automatic control, a manual drive device is optional; a valve that needs to be opened and closed quickly can be equipped with a pneumatic or pneumatic-hydraulic linkage drive device; a valve that needs automatic control or remote control can be equipped with an electric drive device; On flammable and explosive pipelines, if an electric device is selected, an explosion-proof electric drive device should be selected.