- Gate valve

-

- DN1000 Extension stem double flange soft seal gate valveDIN F4 resilient seated gate valveDN450-1200 Resilient Seated Gate ValveDIN F5 resilient seated gate valveSocket connection soft seal gate valveUnderground cap soft seal gate valveBS5163 rising stem soft seal gate valveHard seal gate valveAPI slab Gate ValveStainless steel flange gate valveWafer knife gate valvePneumatic gate valveSoft seal gate valveExtension stem gate valveUL/FM fire protection groove ends gate valveRising stem forged steel gate valvecarbon steel gate valveStainless steel threaded gate valveDIN soft seal gate valveANSI soft sealing gate valve 200PSICast iron gate valveBS resilient seated gate valve

- Butterfly valve

-

- DN900 pneumatic triple eccentric hard seal butterfly valveD643H Triple Eccentric Butterfly ValveD343H Hard seal butterfly valveMulti standard EPDM seated butterfly valveSingle flange butterfly valveDN2000 Double eccentric butterfly valveFlange butterfly valveLug butterfly valveWafer butterfly valve with handleWorm gear operated butterfly valveWafer lined fluorine butterfly valveStainless steel wafer butterfly valveStainless steel flanged butterfly valveThree eccentric flange butterfly valvePneumatic flanged butterfly valvePneumatic wafer butterfly valveTriple eccentric butterfly valve wafer typeWafer butterfly valve ULC approvedInflatable seat butterfly valveHigh performance butterfly valveGrooved end butterfly valveElectric soft seal butterfly valveFlange fluorine lined butterfly valveHandle aluminum butterfly valveWorm Gear Aluminum Butterfly ValveFull PTFE lined butterfly valve wafer typeOne stem no-pin wafer butterfly valveMulti standard aluminum stem butterfly valveStainless Steel wafer Butterfly ValveAluminium handle operated lug butterfly valveLever Operated Flange Butterfly ValveButterfly valve stemButterfly valve discButterfly valve seat

- Ball valve

-

- DN1400 top-mounted eccentric semi-ball valveFlanged three-way ball valveFully welded ball valveNatural gas ball valveHigh platform flange ball valve1 PC ball valveFixed ball valvePTFE seat flanged ball valveMetal seat ball valveAPI 6D ball valve3 Piece ball valveFull Bore 3 way ball valve L-Port3 Way T-Port ball valve2PC Ball valve female thread stainless steel

- Globe Valve

-

- API Carbon Steel Globe ValveBellows Globe ValveStainless steel flange globe valveStainless steel thread S type globe valveStainless steel thread B type globe valveCast Steel Globe ValvePiston Globe ValveWCB Carbon Steel Globe Check Valveelectric motorized control stainless steel SS316 globe valveBrass Globe ValveCryogenic Globe valveHT200 Globe ValveThreaded Stainless Steel Globe ValveGG25 Globe ValveANSI API Cast Steel And Stainless Steel Globe valve

- Check valve

-

- Rubber seal check valveDN800 Slow closing check valveDN800 Rubber Disc Check ValveButterfly Buffering Check Valvecheck valve with counter weightSilent Check ValveWCB Swing check valveSwing Check ValveSingle Chip Check Valve H74WStainless Steel Wafer Check ValveSwing Start Check ValveFoot check valveAPI Swing Check ValveDIN Flange check valveSingle plate check valveLifting Check ValveBottom ValveHammer Diminish Noises Check ValveWafer Check ValveWafer dual plate check valve

- Control valve

-

- Static Balancing ValveCage Guided Sleeve Globe Control ValveDN1000 Piston Flow Regulating ValveDN1600 Electric Actuator Flow Regulating ValvePneumatic Flanged Butterfly ValvePneumatic Wafer Butterfly ValveAngle Seat ValvePneumatic gate valveElectric three-way control valveElectric sleeve control valve

- Water Meter

-

- Vertical Type Water MetersStainless steel threaded water meterPiston water meterPlastic water meterMore flow rotor dry water meterspiral vane flange water meterCI wotlman water meter with pulse outputLXCLG(R) Vertical removable element woltman cold (hot) water meterSingle flow rotor dry water meterPrepaid Token Water MeterElectromagnetic flowmeterRotary Piston Liquid Sealed Water MeterRotary Piston Liquid Sealed Water Meter

- Air valve

-

- Double ball exhaust valveDoubleair Air Valve SaudiDoubleair Air Valve Southeast AsiaDoubleair Air Valve South AmericaDouble Air ValveThreaded Air ValveSingle Air ValveTriple Functions Air ValveAutomatic Air Release ValveAutomatic release valveAutomatic exhaust valveComposite Exhaust Air ValveBrass exhaust valveDouble Ball Air Valve

- Pipe Repair & Coupling

-

- Flexible Multi-Function Pipe Coupling ZFJ-SSS Semi-Circle Pipe Repair Clamp SJW-HDuctile Iron Band Repair ClampStainless Steel Band Repair ClampDouble-Section Pipe Repair CouplingFolding Type Pipe RepairSingle-Section Multi-Function Pipe Coupling MF-SGear-Ring Type Multi-Function Pipe Coupling GR-SZBW Damping Corrugated Hose

- Dismantling Joint

-

- VSSJAFC(CC2F) Detachable Flange Transmission JointVSSJA-2(B2F) Double Flange Limited Expansion JointVSSJA-1(BF) Single Flange Limited Expansion JointVSSJA(AF) Flange Loose Expansion JointJGD-B Threaded Rubber JointZBW Damping Corrugated HoseKXT-S Flexible Dual-Spherical Rubber JointKXT Rubber Soft JointFlange Adaptor

What accessories are needed for control valves?

The introduction of the main accessories of the control valve:

In the following cases, the positioner should be equipped:

1. When the medium pressure is high, and the differential pressure is large;

2. When the caliber of the regulating valve is large (DN>100);

3. High or low-temperature control valves;

4. When there is a need to increase the operating speed of the regulating valve;

5. When operating an actuator with a non-standard spring using a standard signal (spring range other than 20 to 100 KPa);

6. When used for split-range control

7. When the valve is to be operated in the reverse direction (air-closed type and air-open type can be converted to each other);

8. When it is necessary to change the flow characteristics of the valve (the positioner cam can be changed);

9. When there is no spring or piston actuator, and proportional action is to be realized

10. When electrical signals are used to operate pneumatic actuators, electrical-pneumatic valve positioners must be distributed.

Solenoid valves:

When the system needs to achieve program control or two-position control, it is necessary to use solenoid valves. Selection of solenoid valves, in addition, to considering AC and DC power supply and voltage, and frequency, must pay attention to solenoid valves and regulating the role of the valve type of relationship, can be equipped with "normally open" or "normally closed."

Suppose you need to increase the capacity of the solenoid valve to shorten the action time. In that case, you can use two solenoid valves or solenoid valves as a pilot valve and large-capacity combination of pneumatic relays.

Pneumatic Relay:

A pneumatic relay is a kind of power amplifier, it can send the pneumatic signal to a distant place, eliminate the lag caused by the lengthening of the signal pipeline, mainly used between the field transmitter and the central control room of the regulating instrument, or between the regulator and the field regulating valve, and there is also a role is to amplify or reduce the signal.

Converters:

The converter is divided into gas-electricity converter and electricity-gas converter, whose function is to realize a specific relationship between gas and electric signals to convert each other. It is mainly used to convert 0~10mA or 4~20mA electric signals or convert 0~100KPa gas signals into 0~10mA or 4~20mA electric signals when manipulating pneumatic actuators with electric signals.

Air Filtration Pressure Reducing Valve:

An air filtration pressure-reducing valve is an accessory in industrial automation instruments. Its primary function is to filter and purify compressed air from the air compressor and stabilize the pressure at the required value. It can be used as the air supply source and pressure stabilizing device for all kinds of pneumatic instruments, solenoid valves, cylinders, spraying equipment and small pneumatic tools.

Self-locking valve (position preserving valve):

A self-locking valve is a device to keep the valve in position. Pneumatic control valve when the gas source failure occurs, the machine can cut off the gas source signal so that the membrane chamber or cylinder pressure signal to maintain a moment before the failure of the state, so that the valve position is also maintained in the position before the failure, to play the role of position preservation.

Valve position transmitter:

When the control valve is away from the control room, in order not to the scene to accurately understand the valve switching position, we must be equipped with a valve position transmitter, that is, the valve opening the amount of institutional displacement, according to a specific law converted into electrical signals sent to the control room, this signal can be reflected in the valve of any opening of the continuous movement can also be considered as the inverse action of the valve positioner.

Travel switch (return signal):

The travel switch reflects the two extreme positions of the valve switch, and at the same time, sends the indication signal device. Based on this signal, the control room can rebel against the valve switch status to take appropriate measures.

Control Valve Arrangement:

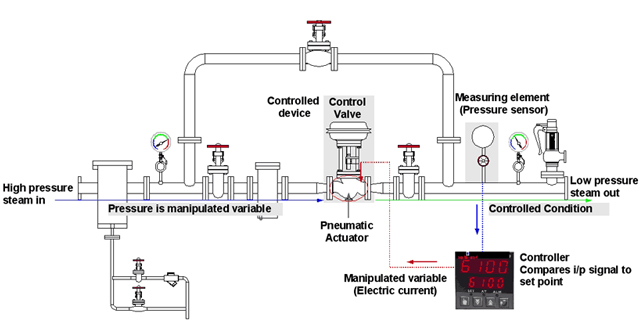

The image below shows how a control valve can be used to control rate of flow in a line. The "controller" receives the pressure signals, compares them with pressure drop for the desired flow and if the actual flow is different, adjusts the control valve to increase or decrease the flow.

Comparable arrangements can be devised to control any of numerous process variables. Temperature, pressure, level and flow rate are the most common controlled variables.