- Gate valve

-

- DN1000 Extension stem double flange soft seal gate valveDIN F4 resilient seated gate valveDN450-1200 Resilient Seated Gate ValveDIN F5 resilient seated gate valveSocket connection soft seal gate valveUnderground cap soft seal gate valveBS5163 rising stem soft seal gate valveHard seal gate valveAPI slab Gate ValveStainless steel flange gate valveWafer knife gate valvePneumatic gate valveSoft seal gate valveExtension stem gate valveUL/FM fire protection groove ends gate valveRising stem forged steel gate valvecarbon steel gate valveStainless steel threaded gate valveDIN soft seal gate valveANSI soft sealing gate valve 200PSICast iron gate valveBS resilient seated gate valve

- Butterfly valve

-

- DN900 pneumatic triple eccentric hard seal butterfly valveD643H Triple Eccentric Butterfly ValveD343H Hard seal butterfly valveMulti standard EPDM seated butterfly valveSingle flange butterfly valveDN2000 Double eccentric butterfly valveFlange butterfly valveLug butterfly valveWafer butterfly valve with handleWorm gear operated butterfly valveWafer lined fluorine butterfly valveStainless steel wafer butterfly valveStainless steel flanged butterfly valveThree eccentric flange butterfly valvePneumatic flanged butterfly valvePneumatic wafer butterfly valveTriple eccentric butterfly valve wafer typeWafer butterfly valve ULC approvedInflatable seat butterfly valveHigh performance butterfly valveGrooved end butterfly valveElectric soft seal butterfly valveFlange fluorine lined butterfly valveHandle aluminum butterfly valveWorm Gear Aluminum Butterfly ValveFull PTFE lined butterfly valve wafer typeOne stem no-pin wafer butterfly valveMulti standard aluminum stem butterfly valveStainless Steel wafer Butterfly ValveAluminium handle operated lug butterfly valveLever Operated Flange Butterfly ValveButterfly valve stemButterfly valve discButterfly valve seat

- Ball valve

-

- DN1400 top-mounted eccentric semi-ball valveFlanged three-way ball valveFully welded ball valveNatural gas ball valveHigh platform flange ball valve1 PC ball valveFixed ball valvePTFE seat flanged ball valveMetal seat ball valveAPI 6D ball valve3 Piece ball valveFull Bore 3 way ball valve L-Port3 Way T-Port ball valve2PC Ball valve female thread stainless steel

- Globe Valve

-

- API Carbon Steel Globe ValveBellows Globe ValveStainless steel flange globe valveStainless steel thread S type globe valveStainless steel thread B type globe valveCast Steel Globe ValvePiston Globe ValveWCB Carbon Steel Globe Check Valveelectric motorized control stainless steel SS316 globe valveBrass Globe ValveCryogenic Globe valveHT200 Globe ValveThreaded Stainless Steel Globe ValveGG25 Globe ValveANSI API Cast Steel And Stainless Steel Globe valve

- Check valve

-

- Rubber seal check valveDN800 Slow closing check valveDN800 Rubber Disc Check ValveButterfly Buffering Check Valvecheck valve with counter weightSilent Check ValveWCB Swing check valveSwing Check ValveSingle Chip Check Valve H74WStainless Steel Wafer Check ValveSwing Start Check ValveFoot check valveAPI Swing Check ValveDIN Flange check valveSingle plate check valveLifting Check ValveBottom ValveHammer Diminish Noises Check ValveWafer Check ValveWafer dual plate check valve

- Control valve

-

- Static Balancing ValveCage Guided Sleeve Globe Control ValveDN1000 Piston Flow Regulating ValveDN1600 Electric Actuator Flow Regulating ValvePneumatic Flanged Butterfly ValvePneumatic Wafer Butterfly ValveAngle Seat ValvePneumatic gate valveElectric three-way control valveElectric sleeve control valve

- Water Meter

-

- Vertical Type Water MetersStainless steel threaded water meterPiston water meterPlastic water meterMore flow rotor dry water meterspiral vane flange water meterCI wotlman water meter with pulse outputLXCLG(R) Vertical removable element woltman cold (hot) water meterSingle flow rotor dry water meterPrepaid Token Water MeterElectromagnetic flowmeterRotary Piston Liquid Sealed Water MeterRotary Piston Liquid Sealed Water Meter

- Air valve

-

- Double ball exhaust valveDoubleair Air Valve SaudiDoubleair Air Valve Southeast AsiaDoubleair Air Valve South AmericaDouble Air ValveThreaded Air ValveSingle Air ValveTriple Functions Air ValveAutomatic Air Release ValveAutomatic release valveAutomatic exhaust valveComposite Exhaust Air ValveBrass exhaust valveDouble Ball Air Valve

- Pipe Repair & Coupling

-

- Flexible Multi-Function Pipe Coupling ZFJ-SSS Semi-Circle Pipe Repair Clamp SJW-HDuctile Iron Band Repair ClampStainless Steel Band Repair ClampDouble-Section Pipe Repair CouplingFolding Type Pipe RepairSingle-Section Multi-Function Pipe Coupling MF-SGear-Ring Type Multi-Function Pipe Coupling GR-SZBW Damping Corrugated Hose

- Dismantling Joint

-

- VSSJAFC(CC2F) Detachable Flange Transmission JointVSSJA-2(B2F) Double Flange Limited Expansion JointVSSJA-1(BF) Single Flange Limited Expansion JointVSSJA(AF) Flange Loose Expansion JointJGD-B Threaded Rubber JointZBW Damping Corrugated HoseKXT-S Flexible Dual-Spherical Rubber JointKXT Rubber Soft JointFlange Adaptor

What is Water Hammer?

What is Water Hammer? And how to eliminate water hammer?

Water hammer is when there is a sudden power failure or when the valve is closed too fast, due to the inertia of the pressure water flow, a water shock wave is generated, just like a hammer, so it is called water hammer. The force generated by the back and forth shock waves of the water flow, sometimes so great, can damage valves and pumps.

"Water hammer effect" means that inside the water pipe, the inner wall of the pipe is smooth and the water flows freely. When the open valve is suddenly closed, the water flow will generate a pressure on the valve and the pipe wall, mainly the valve. Due to the smooth pipe wall, the subsequent water flow will Under the action, it quickly reaches the maximum and produces damage.

This is the "water hammer effect" in fluid mechanics, that is, positive water hammer. This factor must be considered in the construction of water supply pipelines. On the contrary, the closed valve suddenly opens;

Finally, there will also be water hammer, called negative water hammer, which also has certain destructive power, but not as great as the former. When the electric water pump unit is suddenly powered off or started, it will also cause pressure shock and water hammer effect.

The shock wave of this pressure Propagation along the pipeline can easily lead to local overpressure of the pipeline, resulting in pipeline rupture and damage to equipment, so water hammer effect protection has become one of the key technologies in water supply projects.

Why does water hammer occur?

1. The valve suddenly opens or closes;

2. The water pump unit suddenly stops or starts;

3. Single-pipe water delivery to high places (water supply terrain height difference exceeds 20 meters);

4. The total head (or working pressure) of the pump is large;

5. The water velocity in the water pipeline is too high;

6. The water pipeline is too long and the terrain changes greatly.

The dangers of water hammer:

The pressure increase caused by water hammer can reach several times or even dozens of times the normal working pressure of the pipeline. Such large pressure fluctuations cause harm to the pipeline system mainly as follows:

1. Cause strong vibration of the pipeline and disconnection of the pipeline joint;

2. The valve is damaged, and the serious pressure is too high to cause the pipe to burst, and the pressure of the water supply network is reduced;

3. On the contrary, if the pressure is too low, the pipe will collapse, and the valve and fixing parts will be damaged;

4. Cause the water pump to reverse, damage the equipment or pipelines in the pump room, seriously cause the pump room to be submerged, cause personal casualties and other major accidents, and affect production and life.

Protective measures to eliminate or mitigate water hammer:

Best Practices to Avoid Water Hammer

There are many protective measures against water hammer, but different measures need to be taken according to the possible causes of water hammer.

1. Reducing the flow rate of the water pipeline can reduce the water hammer pressure to a certain extent, but it will increase the diameter of the water pipeline and increase the project investment. When laying out water pipelines, consideration should be given to avoiding humps or drastic changes in slope.

(1)Reduce the length of the water pipeline, the longer the pipeline, the greater the water hammer value when the pump is stopped. Change from one pumping station to two pumping stations, and connect the two pumping stations with a suction well.

(2)The size of the water hammer when the pump is stopped is mainly related to the geometric head of the pump room. The higher the geometric head, the greater the water hammer when the pump is stopped. Therefore, a reasonable pump head should be selected according to the actual local conditions. the

(3)After stopping the pump in an accident, wait until the pipeline behind the check valve is filled with water before starting the pump.

Do not fully open the outlet valve of the water pump when starting the pump, otherwise a large water impact will be generated. Most of the major water hammer accidents in many pumping stations occur under such circumstances.

2. Set up water hammer elimination device

(1) Using constant pressure control technology;

The PLC automatic control system is adopted to control the frequency conversion and speed regulation of the pumps, and to automatically control the operation of the entire water supply pump room system. Since the pressure of the water supply pipe network changes continuously with the change of working conditions, low pressure or overpressure often occurs during the operation of the system, which is prone to water hammer, resulting in damage to pipes and equipment.

PLC automatic control system is adopted to control the pipe network. Pressure detection, feedback control of pump start, stop and speed adjustment, control flow, and then maintain a certain level of pressure. The water supply pressure of the pump can be set by controlling the microcomputer to maintain constant pressure water supply, avoiding excessive pressure fluctuations, so that The probability of water hammer is reduced.

(2) Install the water hammer eliminator;

This equipment mainly prevents water hammer when the pump is stopped. It is generally installed near the outlet pipe of the pump. It uses the pressure of the pipe itself as the power to realize low-pressure automatic action, that is, when the pressure in the pipe is lower than the set protection value, the drain will automatically open and discharge water. Pressure relief to balance the pressure of local pipelines and prevent the impact of water hammer on equipment and pipelines. Generally, eliminators can be divided into two types: mechanical and hydraulic. reset.

(3) Install a slow-closing check valve on the large-diameter water pump outlet pipe;

It can effectively eliminate the water hammer when the pump is stopped, but because there is a certain amount of water backflow when the valve is actuated, the suction well must have an overflow pipe. There are two types of slow-closing check valves: hammer type and energy storage type. This kind of valve can adjust the closing time of the valve within a certain range according to the needs. Generally, 70% to 80% of the valve is closed within 3 to 7 s after the power failure, and the closing time of the remaining 20% to 30% is adjusted according to the conditions of the water pump and pipeline, generally in the range of 10 to 30 s. It is worth noting that when there is a hump in the pipeline to bridge the water hammer, the effect of the slow-closing check valve is very limited.

(4) Set up a bypass pipe (valve) in the pump station;

When the pump system is running normally, the check valve is closed because the water pressure on the pressure water side of the pump is higher than the water pressure on the suction side. When the power failure suddenly stops the pump, the pressure at the outlet of the pumping station drops sharply, while the pressure on the suction side rises sharply.

Under this differential pressure, the transient high-pressure water in the water suction main pipe is the transient low-pressure water that pushes the check valve plate to flow to the pressure water main pipe, and makes the low water pressure there rise; on the other hand, the water pump The water hammer boost on the suction side is also reduced. In this way, the rise and fall of water hammer on both sides of the pumping station are controlled, thereby effectively reducing and preventing water hammer hazards. the

(5) Set multi-stage check valve;

In the longer water pipeline, add one or more check valves, divide the water pipeline into several sections, and set a check valve on each section. When the water in the water pipe flows back during the water hammer process, the check valves are closed one after another to divide the backflush flow into several sections. Since the hydrostatic head in each section of the water pipe (or backflush flow section) is quite small, the water flow is reduced.

Hammer Boost. This protective measure can be effectively used in situations where the geometrical water supply height difference is large; but it cannot eliminate the possibility of water column separation. Its biggest disadvantage is: the power consumption of the water pump increases during normal operation, and the cost of water supply increases.

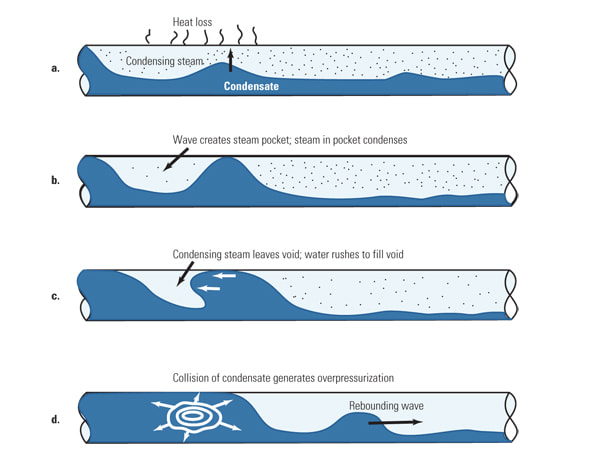

Below Figure depicts the four-step sequence that causes condensation-induced water hammer.

(a) As condensing steam loses its heat to the pipe wall and cooler condensate, it changes phase from a vapor to a liquid.

(b) Working together, the condensation and flow of steam produce waves that build until they fill the pipe cross section, trapping steam between their peaks. The trapped steam then condenses rapidly.

(c) Resulting liquid, due to condensation of steam, occupies up to 1,000 times less space than it did as steam. The pressure in the void falls to a much lower level than that of the steam surrounding it. The void then collapses as the water, under steam pressure, rushes in.

(d) The collision of the water and condensate produces a local, pressurized pulse of water that rebounds down the pipe.