- Gate valve

-

- DN1000 Extension stem double flange soft seal gate valveDIN F4 resilient seated gate valveDN450-1200 Resilient Seated Gate ValveDIN F5 resilient seated gate valveSocket connection soft seal gate valveUnderground cap soft seal gate valveBS5163 rising stem soft seal gate valveHard seal gate valveAPI slab Gate ValveStainless steel flange gate valveWafer knife gate valvePneumatic gate valveSoft seal gate valveExtension stem gate valveUL/FM fire protection groove ends gate valveRising stem forged steel gate valvecarbon steel gate valveStainless steel threaded gate valveDIN soft seal gate valveANSI soft sealing gate valve 200PSICast iron gate valveBS resilient seated gate valve

- Butterfly valve

-

- DN900 pneumatic triple eccentric hard seal butterfly valveD643H Triple Eccentric Butterfly ValveD343H Hard seal butterfly valveMulti standard EPDM seated butterfly valveSingle flange butterfly valveDN2000 Double eccentric butterfly valveFlange butterfly valveLug butterfly valveWafer butterfly valve with handleWorm gear operated butterfly valveWafer lined fluorine butterfly valveStainless steel wafer butterfly valveStainless steel flanged butterfly valveThree eccentric flange butterfly valvePneumatic flanged butterfly valvePneumatic wafer butterfly valveTriple eccentric butterfly valve wafer typeWafer butterfly valve ULC approvedInflatable seat butterfly valveHigh performance butterfly valveGrooved end butterfly valveElectric soft seal butterfly valveFlange fluorine lined butterfly valveHandle aluminum butterfly valveWorm Gear Aluminum Butterfly ValveFull PTFE lined butterfly valve wafer typeOne stem no-pin wafer butterfly valveMulti standard aluminum stem butterfly valveStainless Steel wafer Butterfly ValveAluminium handle operated lug butterfly valveLever Operated Flange Butterfly ValveButterfly valve stemButterfly valve discButterfly valve seat

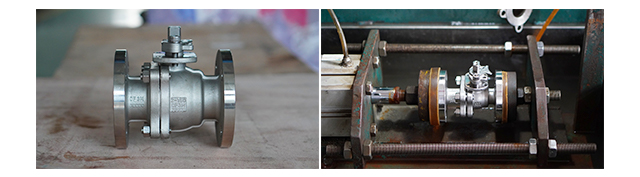

- Ball valve

-

- DN1400 top-mounted eccentric semi-ball valveFlanged three-way ball valveFully welded ball valveNatural gas ball valveHigh platform flange ball valve1 PC ball valveFixed ball valvePTFE seat flanged ball valveMetal seat ball valveAPI 6D ball valve3 Piece ball valveFull Bore 3 way ball valve L-Port3 Way T-Port ball valve2PC Ball valve female thread stainless steel

- Globe Valve

-

- API Carbon Steel Globe ValveBellows Globe ValveStainless steel flange globe valveStainless steel thread S type globe valveStainless steel thread B type globe valveCast Steel Globe ValvePiston Globe ValveWCB Carbon Steel Globe Check Valveelectric motorized control stainless steel SS316 globe valveBrass Globe ValveCryogenic Globe valveHT200 Globe ValveThreaded Stainless Steel Globe ValveGG25 Globe ValveANSI API Cast Steel And Stainless Steel Globe valve

- Check valve

-

- Rubber seal check valveDN800 Slow closing check valveDN800 Rubber Disc Check ValveButterfly Buffering Check Valvecheck valve with counter weightSilent Check ValveWCB Swing check valveSwing Check ValveSingle Chip Check Valve H74WStainless Steel Wafer Check ValveSwing Start Check ValveFoot check valveAPI Swing Check ValveDIN Flange check valveSingle plate check valveLifting Check ValveBottom ValveHammer Diminish Noises Check ValveWafer Check ValveWafer dual plate check valve

- Control valve

-

- Static Balancing ValveCage Guided Sleeve Globe Control ValveDN1000 Piston Flow Regulating ValveDN1600 Electric Actuator Flow Regulating ValvePneumatic Flanged Butterfly ValvePneumatic Wafer Butterfly ValveAngle Seat ValvePneumatic gate valveElectric three-way control valveElectric sleeve control valve

- Water Meter

-

- Vertical Type Water MetersStainless steel threaded water meterPiston water meterPlastic water meterMore flow rotor dry water meterspiral vane flange water meterCI wotlman water meter with pulse outputLXCLG(R) Vertical removable element woltman cold (hot) water meterSingle flow rotor dry water meterPrepaid Token Water MeterElectromagnetic flowmeterRotary Piston Liquid Sealed Water MeterRotary Piston Liquid Sealed Water Meter

- Air valve

-

- Double ball exhaust valveDoubleair Air Valve SaudiDoubleair Air Valve Southeast AsiaDoubleair Air Valve South AmericaDouble Air ValveThreaded Air ValveSingle Air ValveTriple Functions Air ValveAutomatic Air Release ValveAutomatic release valveAutomatic exhaust valveComposite Exhaust Air ValveBrass exhaust valveDouble Ball Air Valve

- Pipe Repair & Coupling

-

- Flexible Multi-Function Pipe Coupling ZFJ-SSS Semi-Circle Pipe Repair Clamp SJW-HDuctile Iron Band Repair ClampStainless Steel Band Repair ClampDouble-Section Pipe Repair CouplingFolding Type Pipe RepairSingle-Section Multi-Function Pipe Coupling MF-SGear-Ring Type Multi-Function Pipe Coupling GR-SZBW Damping Corrugated Hose

- Dismantling Joint

-

- VSSJAFC(CC2F) Detachable Flange Transmission JointVSSJA-2(B2F) Double Flange Limited Expansion JointVSSJA-1(BF) Single Flange Limited Expansion JointVSSJA(AF) Flange Loose Expansion JointJGD-B Threaded Rubber JointZBW Damping Corrugated HoseKXT-S Flexible Dual-Spherical Rubber JointKXT Rubber Soft JointFlange Adaptor

What working conditions are ball valves suitable for?

Advantages of ball valves:

①Has the lowest flow resistance (actually 0);

②Because it will not get stuck during operation (when there is no lubricant), it can be reliably used in corrosive media and low-boiling point liquids;

③Complete sealing can be achieved within a wide range of pressure and temperature;

④Rapid opening and closing can be achieved. The opening and closing time of some structures is only 0.05~0.1s to ensure that it can be used in the automation system of the test bench. When opening and closing the valve quickly, there is no impact in the operation.

⑤The spherical closing member can automatically locate at the boundary position;

⑥The working medium is reliably sealed on both sides;

⑦When fully open and fully closed, the sealing surfaces of the ball and valve seat are isolated from the medium, so the medium passing through the valve at high speed will not cause erosion of the sealing surface;

⑧With compact structure and light weight, it can be considered as a reasonable valve structure for low-temperature medium systems;

⑨The valve body is symmetrical, especially the welded valve body structure, which can withstand the stress from the pipeline well;

⑩The closing part can withstand the high pressure difference during closing.

⑪The ball valve with a fully welded body can be buried directly underground so that the valve internal parts are not corroded and has a service life of ≤30 years. It is an ideal valve for oil and natural gas pipelines.

Disadvantages of ball valves:

①Because the main valve seat sealing ring material of the ball valve is polytetrafluoroethylene, it is inert to almost all chemical substances, and has a small friction coefficient, stable performance, not easy to age, wide temperature range and sealing performance Excellent comprehensive features.

However, the physical properties of PTFE, including a high coefficient of expansion, sensitivity to cold flow and poor thermal conductivity, require that the valve seat seal must be designed around these properties. Therefore, when the sealing material hardens, the reliability of the seal is compromised. Moreover, PTFE has a low temperature resistance level and can only be used below 180°C. Above this temperature, the sealing material will age. When considering long-term use, it is generally only used at 120°C.

②Its adjustment performance is worse than that of the stop valve, especially the pneumatic valve (or electric valve).

The many unique characteristics of ball valves determine that ball valves are used in a relatively wide range of applications. Usually, they are used in two-position adjustment, strict sealing performance, mud, wear, shrinkage channel, rapid opening and closing action (1/4 turn opening and closing), high pressure cut-off ( Ball valves are recommended for pipeline systems with large pressure difference), low noise, cavitation and vaporization phenomena, a small amount of leakage to the atmosphere, small operating torque, and small fluid resistance.

Ball valves are also suitable for pipeline systems with light structure, low pressure cutoff (small pressure difference), and corrosive media. Ball valves can also be used in cryogenic (cryogenic) devices and piping systems.

Applicable principles of ball valves:

2. If it is buried on the ground, choose a ball valve with a full-diameter welded connection or a flange connection; for a branch pipe, choose a ball valve with a flange connection, a welded connection, a full-diameter or a reduced diameter.

3. For product oil transportation pipelines and storage equipment, flange-connected ball valves are used.

4. On city gas and natural gas pipelines, floating ball valves with flange connection and internal thread connection are used.

5. In the oxygen pipeline system in the metallurgical system, fixed ball valves with flange connections should be selected that have undergone strict degreasing treatment.

6. For piping systems and devices with low-temperature media, low-temperature ball valves with valve covers should be used.

7. For the piping system of the catalytic cracking unit of the oil refining unit, a lift-rod ball valve can be used.

8. For devices and piping systems with corrosive media such as acid and alkali in chemical systems, it is appropriate to use all-stainless steel ball valves made of austenitic stainless steel and with polytetrafluoroethylene as the valve seat seal.

9. Metal-to-metal sealing ball valves can be used for pipeline systems or devices with high-temperature media in metallurgical systems, power systems, petrochemical installations, and urban heating systems.

10. When flow adjustment is required, a worm gear-driven, pneumatic or electric regulating ball valve with a V-shaped opening can be used.

Ball valves are widely used, and the variety and quantity are still expanding, and are developing towards high pressure, high temperature, large diameter, high sealing, long life, excellent regulating performance and multi-functionality of one valve. Its reliability and other performance indicators All have reached a high level and can partially replace gate valves, stop valves and regulating valves.

With the technological advancement of ball valves, they will be more widely used in the foreseeable short term, especially on oil and gas pipelines, cracking units in oil refining, and in the nuclear industry. In addition, ball valves will also become one of the leading valve types in large and medium diameter, medium and low pressure fields in other industries.